Your cart is currently empty!

Category: Knowledge Base SVA1000X Series

Quickly Monitor FM Deviation using a Spectrum Analyser

Spectrum analysers are very useful tools for observing radio transmissions. One of the more common applications is to monitor a known channel or band of frequencies. In this note, we are going to show how to quickly capture an FM radio transmission and then configure the analyser to provide us with the frequency deviation of that signal.

NOTE: If you are unsure of the power of the signal that you are attempting to measure, it may be a good idea to add external attenuation to the RF input of the analyser to help prevent damage to the analysers sensitive measurement circuit. You are ultimately responsible for any damage caused by excessive signal power.

- Connect the appropriate antenna to receive the signals of interest:

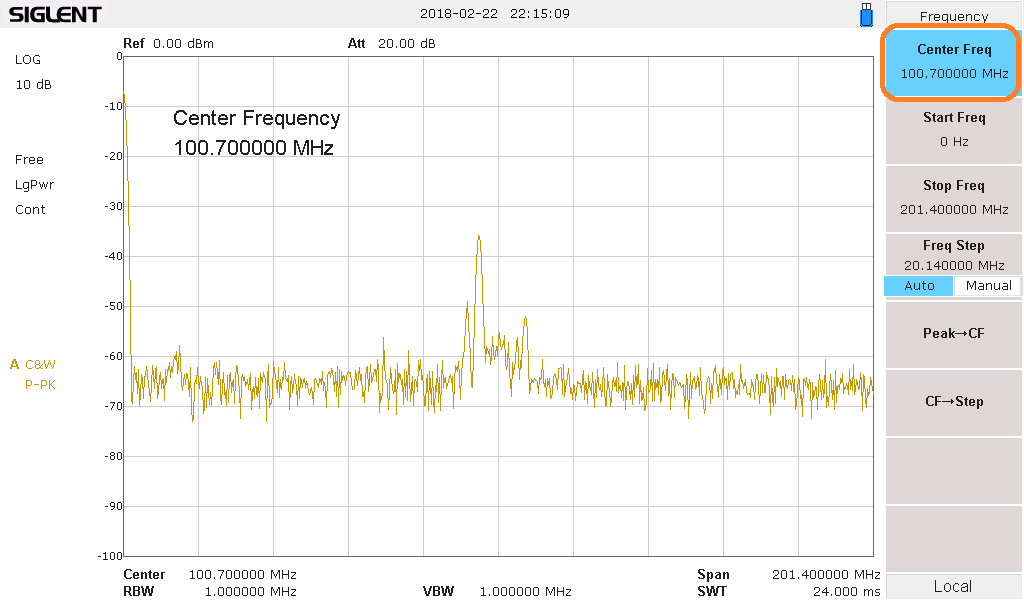

2. Press Frequency > Center Frequency and set the center frequency to match the frequency of interest. Here, we are setting the center frequency to 100.7 MHz, a local FM radio station:

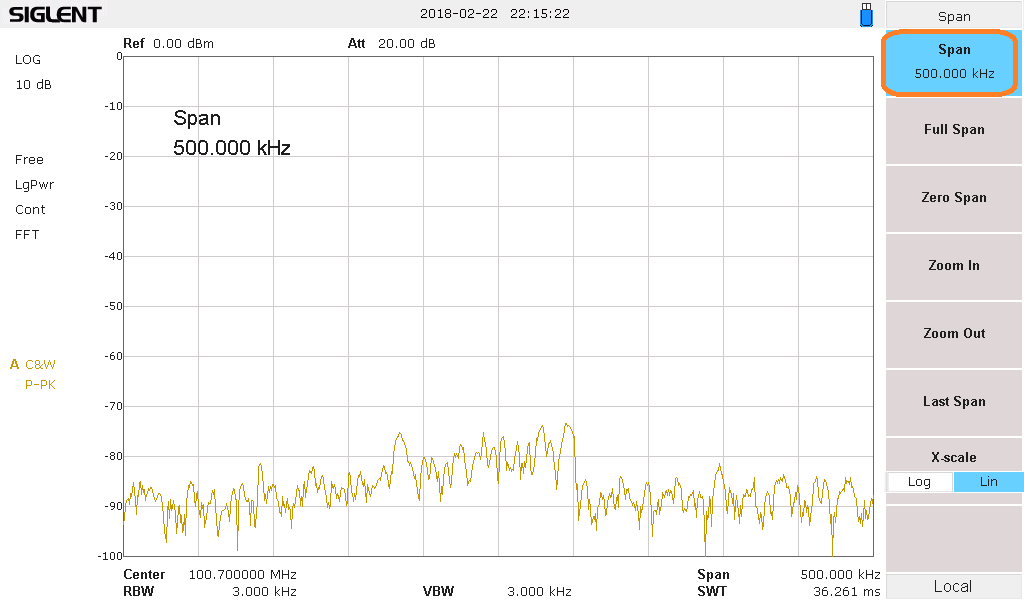

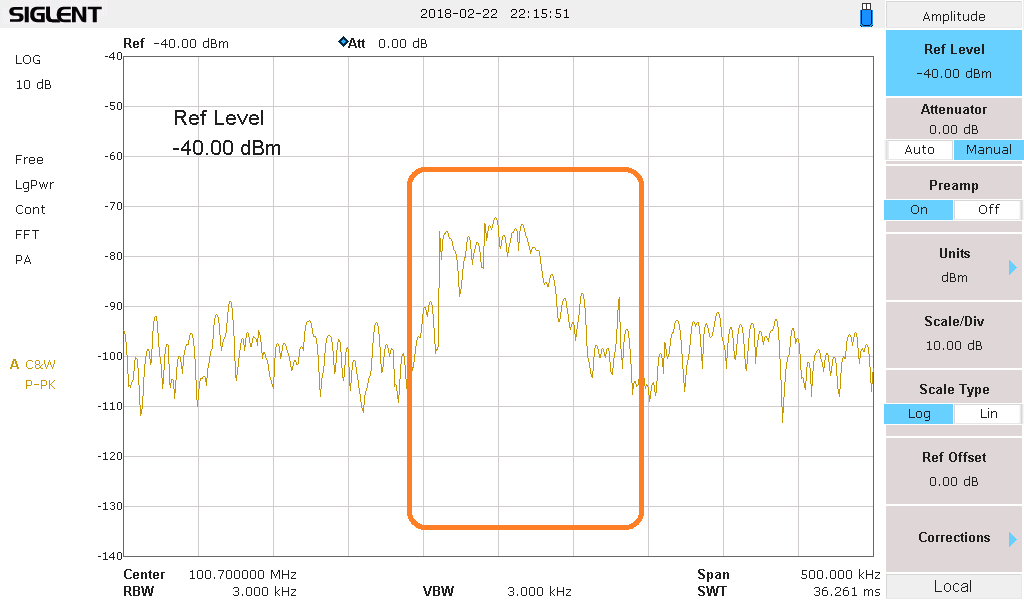

2. Press Span > Span and set the span to an appropriate level for your application. If you are looking at a single channel, you can set the span to 500 kHz or so. This will allow you to observe the channel and the full range of the frequency deviation:

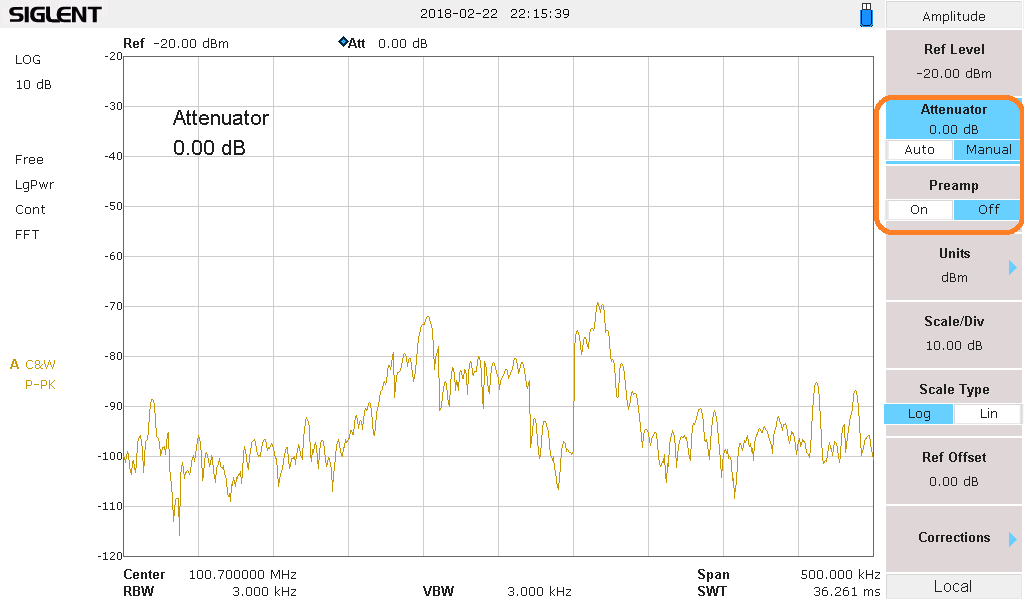

3. If the signal is still very low or cannot be easily observed through the noise, you can lower the attenuation by pressing Amplitude > and lower the Attenuator setting. You can also enable the preamplifier.

NOTE: Use caution as lowering the attenuation and enabling the preamplifier makes the instrument more susceptible to damage due to overpowering the input.

After adjusting the preamp and attenuator, you can see the signal rise out of the noise:

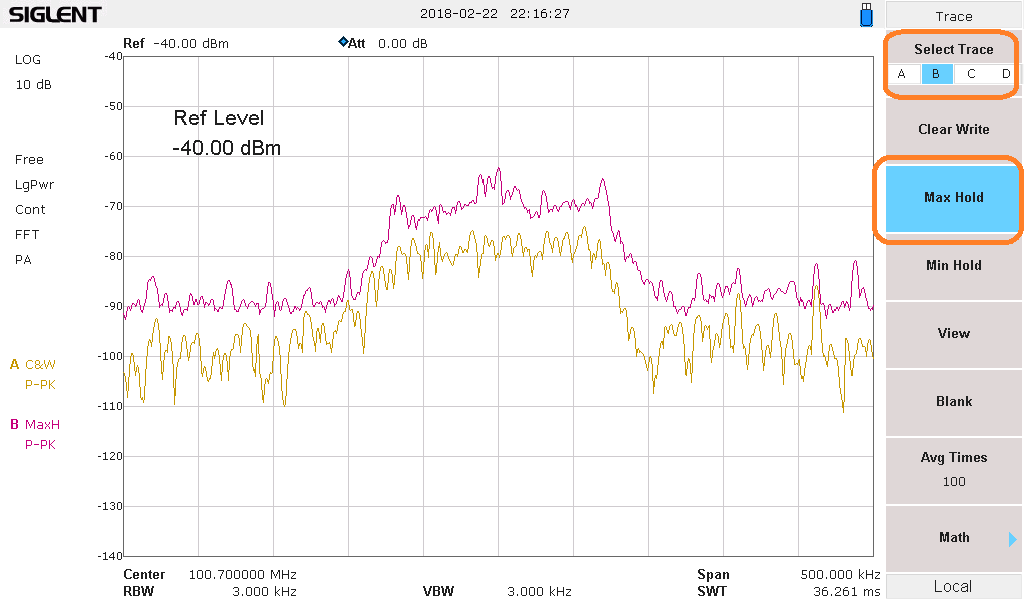

4. Now, we can activate another trace on the display and we can set it to be a Max Hold trace type. This trace type records the largest amplitude for each frequency bin and it will stay there until it has been manually cleared. Over time and successive scans, the Max Hold trace will show us the frequency deviation of our signal.

Note that trace 1 type is Clear Write. This overwrites each frequency bin amplitude with a new value for each scan:

The FM deviation of this signal is approximately 4 divisions.

The Span is 500 kHz and there are 10 divisions on the display. Therefore, each division is 50 kHz. So, the FM signal deviates around 200 kHz.

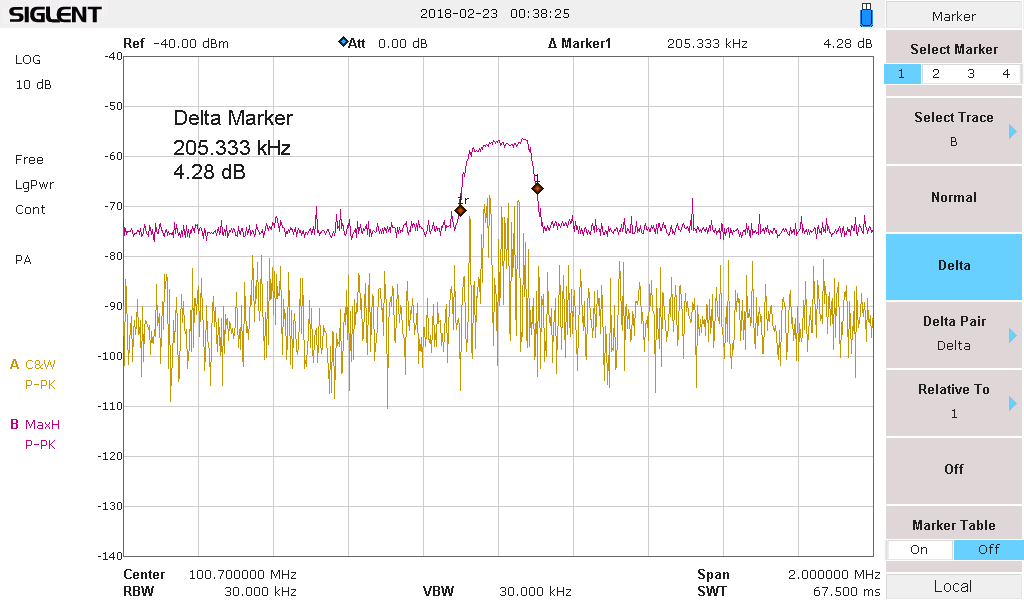

You can use markers for more accurate measurements:

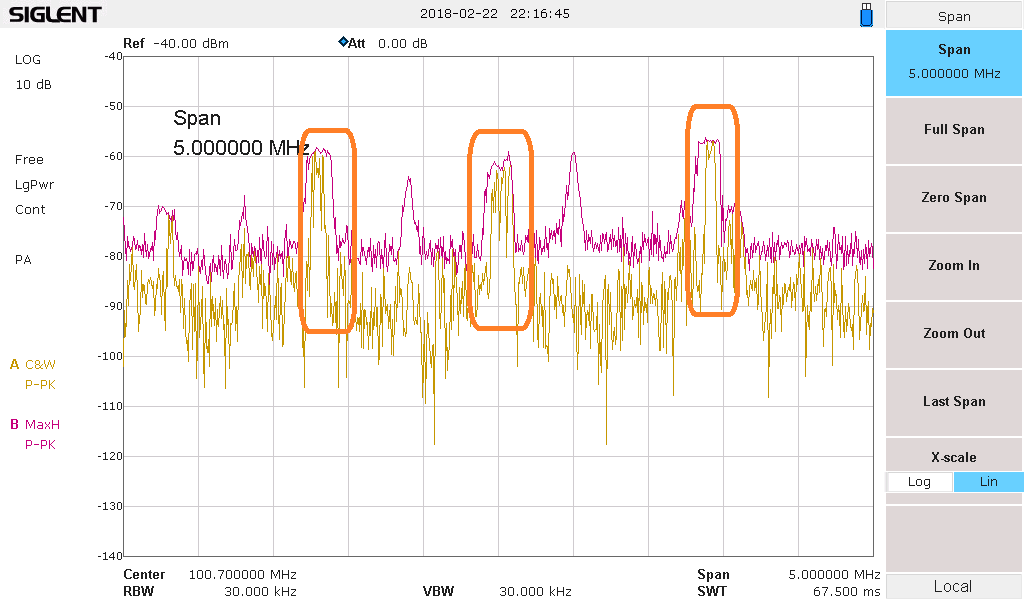

Or adjust the span to see adjacent transmissions:

Electromagnetic Compliance: Troubleshooting with Near-Field and Current Probes

Electromagnetic interference (EMI) can cause a host of problems, especially when developing a product or attempting to pass mandatory electromagnetic compliance (EMC) tests. Garbled displays, bad data, or complete malfunctions can occur when a design is effected by EMI. To minimise the effects of interference, government agencies like the Federal Communications Commission (FCC) in North America create and enforce standards that set limits on the EM output of a product type. Testing to the specifications is commonly referred to as Electromagnetic Compliance (EMC) testing.

Many EMC test failures stem from the interaction of unintentional radio frequency (RF) emissions with a circuit or element within the design itself. The electric and magnetic fields that cause this interference are not visible to the unaided eye, which can present complications when trying to isolate the root cause and minimize the effects of the EMI.

- What is causing the issue?

- Where is the source of the signal or energy causing the radiation?

- How can I fix it?

Fortunately, there are simple tools and techniques that can help identify the sources of EMI. Once you can identify the source, you can begin to build up a list of solutions to the problems. These techniques are not part of the mandatory compliance tests required to pass EMC testing. Rather, these are pre-compliance test techniques that help identify potential areas of EMI as quickly as possible without the burden of expensive test equipment and setups.

In this application note, we are going to introduce some common pre-compliance test techniques for identifying potential problematic EMI sources using near-field and current probes. These techniques can save you time and money by isolating problem areas quickly, and with a little fixturing, you can create repeatable test stations to help correlate data. This knowledge can then be used to “design for EMC” in your future products.

NOTE: Pre-compliance tests are designed to help identify and resolve issues that may hinder passing full compliance tests. Pre-compliance testing is not a replacement for full compliance testing at a certified lab.

ELECTROMAGNETIC RADIATION BASICS

In electronics, EM radiation is most commonly caused by a current flow or voltage build-up along or through a conductor. This includes traces on a PC board, discrete wires, component leads/pins, connectors, or any other metal, including the chassis, rack, or product enclosure. Recall that EM radiation is actually a combination of electric and magnetic field components. It is described as the propagation of orthogonal time-varying electric and magnetic fields as shown in figure 1.

Figure 1: Electromagnetic wave propagation out of the page (top left), to the right (top right) and out of the page at an angle. Note that the E and H fields are orthogonal (90°) to one another.

While the electric (E) and magnetic (H) fields are created by the same phenomena, they physically behave quite differently in the environment. Magnetic fields are only created by moving charges (current). In most circuits, current is conducted by traces on the PC board, component pins/leas, and discrete wires. Therefore, the magnetic field tends to dominate the EM radiation produced by the traces and wires that route signals and power to different parts of the design.

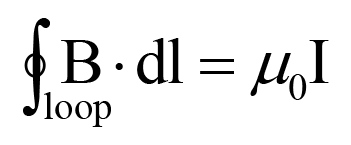

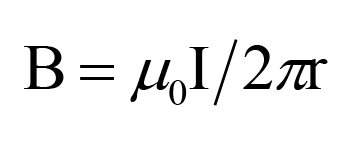

Visualising the magnetic field can be a bit easier if you go back to your Physics texts. Recall that the magnetic field of an infinitely long straight wire can be calculated by applying Ampere’s law:

For a circular path centered on the wire, the summation becomes:

Where:

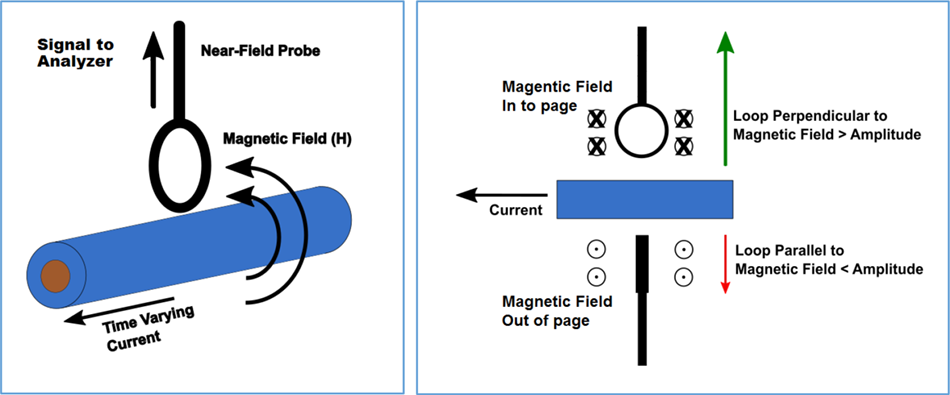

Figure 2 is a physical representation of this relationship. Note, this is also described by the “right-hand-rule” wherein if you were to point the thumb of your right hand in the direction of the current flow, then the magnetic field lines form concentric rings that wrap around the conductor in the direction of your fingers.

Figure 2: Magnetic field produced by a currentUnlike the magnetic field, electric fields can be created by moving or static charges. In this way, electric field effects dominate over magnetic fields when searching for EM radiation on surfaces like heatsinks or metal enclosures. The effects of the electric field also tend to dominate further away from the source (far-field). Far-field measurements are more susceptible to error due to environmental factors like radio stations, WiFi, and intentional RF. Far-field measurements, like those performed during radiated emissions portion of a compliance test, require more setup, equipment, and expertise than near-field.

By measuring the amplitude and frequency of the magnetic and electric fields that are generated by elements of a product, we can identify the areas that have the highest potential to cause EMI issues.

EQUIPMENT LIST

Here are the basic requirements for a near-field troubleshooting kit:

Spectrum Analyzer/EMI Receiver: Measures RF power with respect to frequency. The analyser should have a maximum frequency of at least 1 GHz, DANL of -100 dBm (-40 dBuV) or less, and a minimum RBW of at least 10 kHz.

Figure 3: A SIGLENT SSA3021X 2.1 GHz spectrum analyser.Near-field probes: Commercial or handmade. Many are magnetic (H) field probes, but there are also electric (E) field probes as well.

Current probes: Commercial or handmade.

50 Ohm cable: Use a cable with connectors that mate to the near-field probes and the RF input of the spectrum analyzer. Many commercial probes can be purchased with a cable and any adapters that may be required.

PROBES

Since EMI cannot directly observed by the human eye, we need some tools to help. Recall that moving charges in a conductor produce magnetic and electric fields that radiate throughout space from the conductor. We can use these fields to induce a voltage in a circuit. Then, measure that induced voltage and therefore indirectly measuring the strength of the original field. The two most common types of probes used in EMI troubleshooting are near-field probes and current clamps.

Magnetic field probes and current clamps operate on a similar principle. The magnetic field that flows through the “loop” area of the probe induces a voltage that can be measured (figure 4). Larger loop areas pick up more magnetic flux, and are therefore better suited to finding smaller signals, but smaller loops offer better spatial resolution. Many kits come with multiple loop sizes (figure 5) to help strike the balance between sensitivity and spatial resolution.

Electric field probes do not generally have a loop area. They pick up the electric field similar to a monopole antenna. The rotation of an electric field probe is not critical as with the magnetic field probe, but the distance from the signal source is.

Here are some guidelines for probing:- Measure the background radiation by powering off the device-under-test and monitor the analyser display. Note any RF that may be caused by background or environmental conditions and retest often.

- Probe displays, communications port terminals, and any cutout/air vent/seam of the enclosure. These are common problem areas.

- E and H field probes positioned closer to the signal source will measure higher amplitudes

- H field probes oriented perpendicular to the magnetic field will measure higher amplitudes than those oriented parallel to the magnetic field.

- Since probe positioning is critical to repeatable measurements, a non-conductive fixture (wood, plastic) to position the device-under-test (DUT) and the probe can be used. Remember, position and orientation are very important. A few millimeters or a few degrees of rotation can cause a big difference in the measured amplitude of a given magnetic field.

Figure 4: Magnetic field probe orientation and position affect measurement amplitude.

Figure 4: Magnetic field probe orientation and position affect measurement amplitude. Figure 5: SIGLENT SRF5030 near-field probe kit.

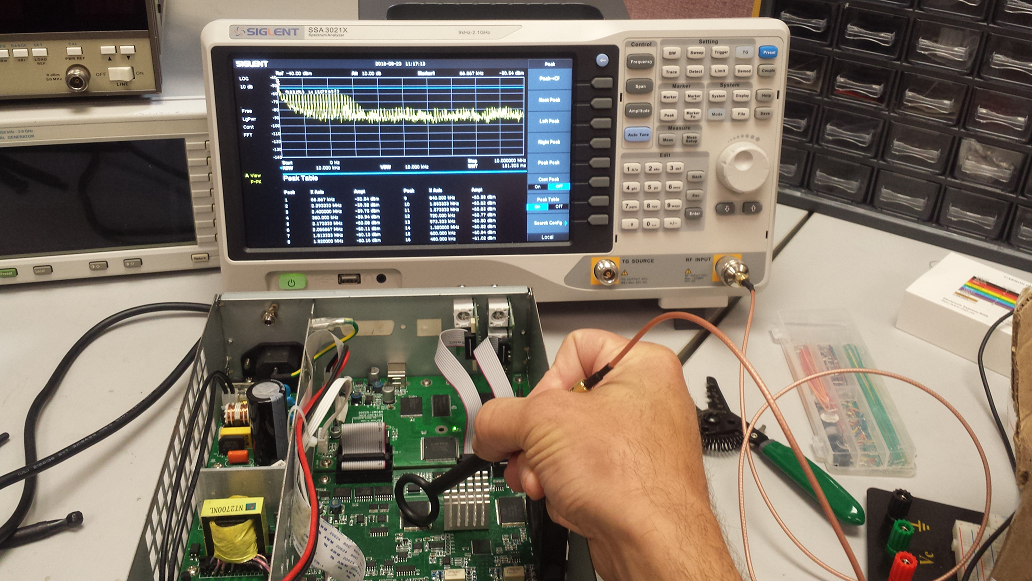

Figure 5: SIGLENT SRF5030 near-field probe kit. Figure 6: Probing a PCB using a SIGLENT SSA3X and SRF5030 probe.

Figure 6: Probing a PCB using a SIGLENT SSA3X and SRF5030 probe.Cables and interconnects can make very effective (and unintentional) antennas if they are not shielded/grounded correctly. Small currents flowing on the outside of the conductor can easily cause radiated emissions that can exceed the set EMC limits. A current clamp can be used with a spectrum analyser to provide insight into the cause of radiating cables/interconnects.

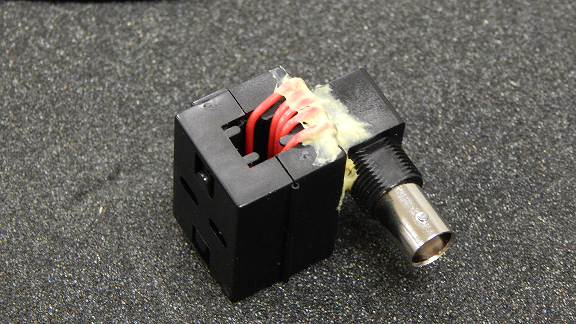

Current clamps operate on the same principle as magnetic loop probes. They can be purchased or made by wrapping a few rounds of wire around a ferrite clamp and epoxy a BNC connector as shown in figure 7. Simply attach the clamp to the cable to be tested, connect it to the spectrum analyser input, and configure the analyser for the frequency span of interest.

Figure 7: A handmade current clamp.Here are some guidelines for probing:

- If in doubt, add an external attenuator to the RF input of the analyser before you start. Power cables or expected high-power applications can have signals that will damage the sensitive RF input of the analyser.

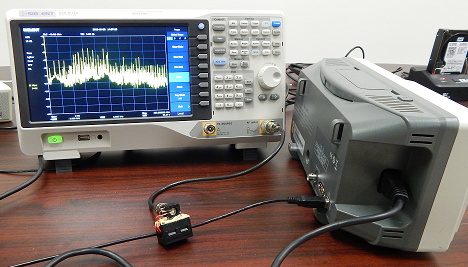

- Test all of the cables that could be connected to the DUT. This includes the power cord, USB, Ethernet, and any other possible connections (figure 8)

Figure 8: Measuring the RFI of a USB cable connected to a scope.- Current clamps, especially handmade, are susceptible to picking up environmental RF that can skew or overwhelm the signals that you wish to measure. Connect and arrange all cables, probes, etc.. and then measure the environmental RF by simply keeping the DUT powered OFF. Then, compare it to measurements made with the DUT ON. It may also be a good idea to retest periodically to account for any environmental changes.

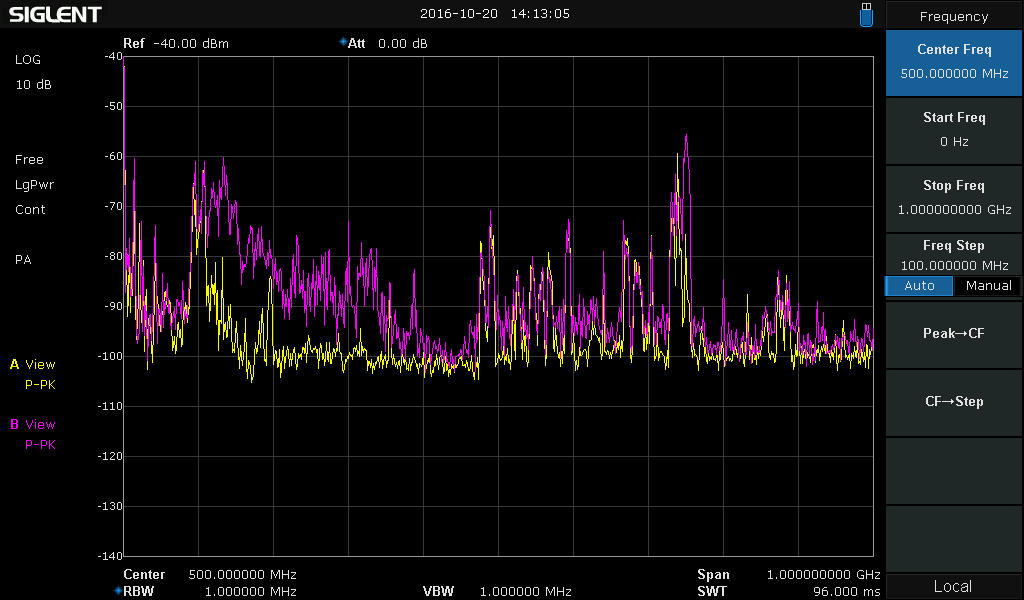

Figure 9: Traces of the environmental pickup from a current clamp (Yellow) and with the DUT powered ON (Pink).- If you have a failed radiated emissions report, start by looking for the failed frequencies or for the first few harmonics of those frequencies.

SCANS AND EVALUATION

It is highly unlikely that data collected during probing will directly correlate to radiated emissions test performance. But, by observing the RF output of cables, switching power supplies, displays, and cutouts, you can have information that can lead to faster troubleshooting if you do happed to fail.

Here are optional techniques that can help provide more insight:

1. Most spectrum analysers do not have pre-selection filters. If you are using a spectrum analyser without pre-selection filters, the peaks you observe may not be real. Analysers without pre-selection filters can create false peaks due to out-of-band signals mixing with the observed signals.

You can test the validity of a peak by adding an external attenuator (3 or 10dB should do). Real peaks will fall by the amount of the attenuator. If the peak falls by more than the attenuator, it is likely to be a false peak. Make a note of the false peaks for comparison with your compliance test results. You can also use pre-selection filters or an EMI receiver, but these tend to be cost prohibitive for most quick testing.

Figure 10 below shows a typical peak confirmation test. The yellow trace was collected without an attenuator. The Pink trace was collected with a 10 dB attenuator added to the RF input of the analyser. In this case, the peaks drop the same amount as the added attenuation. This helps affirm that the peaks are likely real and not products of out-of-band signals.

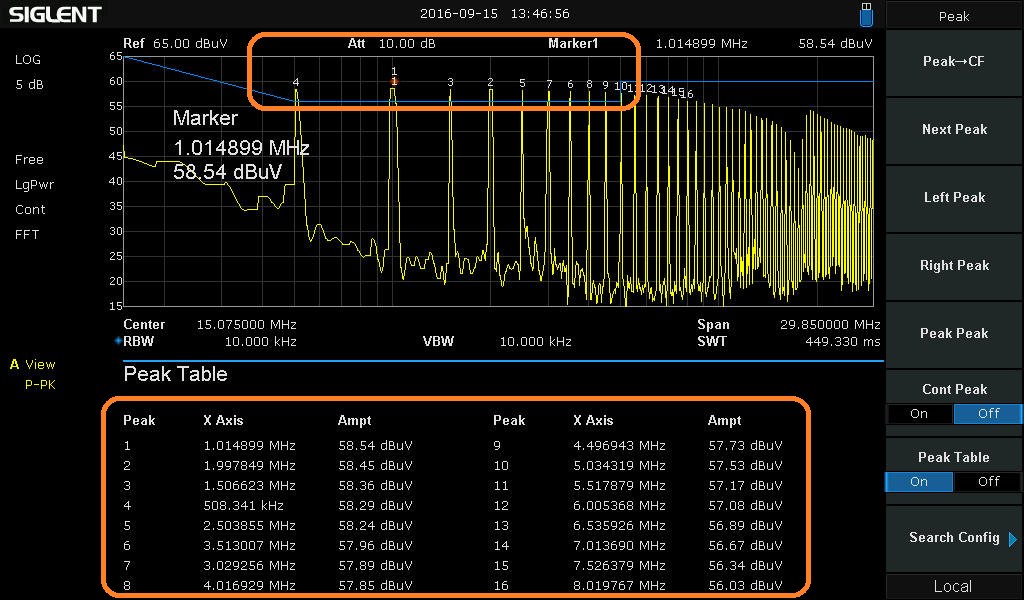

Figure 10: Comparison of two scans using the marker table function of the SIGLENT SSA3000X spectrum analyser. The Yellow trace was collected without attenuation while the Pink trace was collected after adding a 10 dB external attenuator.2. Many spectrum analysers have Max Hold trace types that will continuously hold the highest amplitudes of each frequency scan. You can enable a single trace as Clear Write to show active RF performance and enable a second trace as Max Hold. This allows you to compare changes in the DUT to the “worst case” data collected and “frozen” using Max Hold.

3. You can use markers and peak tables to clearly indicate peak frequencies and amplitudes, if available.

Figure 11: SSA3000X analyzer with Peak table and markers activated.CONCLUSION

- Magnetic fields are produced by current flow. Use a magnetic (H) near-field probe to identify EM radiation near traces, wires, and ribbon/flex cables.

- Electric fields can be produced by current flow or static charge build up. Use an electric (E) near-field probe to identify EM radiation on metal surfaces like heat-sinks, enclosures, display bonding/edges, and slots/cutouts.

- Use current clamps to identify potential radiation and resonance from cables, wires, and interconnects

- Displays, cutouts/holes/seams in the chassis, ribbon cables, and communications ports/busses are the most likely cause of radiated emission failures.

- Use conductive tape or aluminium foil to cover areas of “leakage”, making sure that the covering is grounded. Rescan with the tape/foil in place to see if it has mitigated the EMI.

- Poorly terminated cables and interconnects also cause radiated issues

- Frequently measure the background effects by removing power from the device-under-test and monitor the output on an analyser. Note any changes and their potential effects on the measurements.

With a few simple tools, you can implement an in-house pre-compliance test process that will minimize the total development time for your products, lower the cost of design, and decrease the amount of testing on future products.

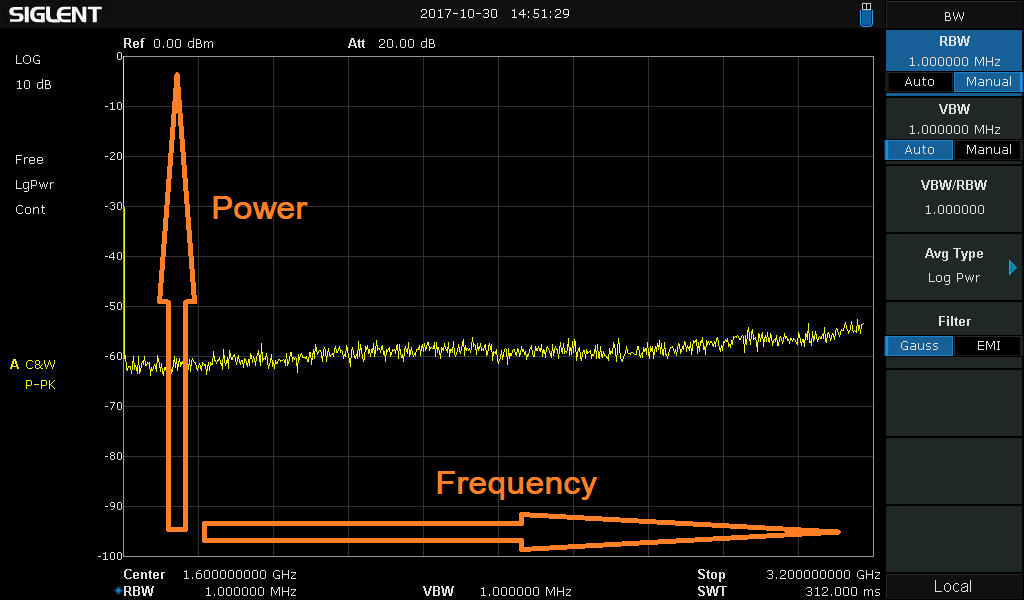

Spectrum Analyser Basics: Bandwidth

Spectrum analysers are useful tools for broadcast monitoring, RF component testing, and EMI troubleshooting. There are a number of common adjustments available with many modern analysers that can optimize performance for a particular application. In this application note, we will introduce resolution bandwidth (RBW) and video bandwidth (VBW) and how they affect measurements.

Resolution Bandwidth (RBW)

Bandwidth is defined as the span of frequencies that are the focus of a particular event. For example, the bandwidth of transmission signal is the span of frequencies that the transmission occupies. The bandwidth of a measurement defines the range of frequencies that were used for the measurement.

In spectrum analysis, the resolution bandwidth (RBW) is defined as the frequency span of the final filter that is applied to the input signal. Smaller RBWs provide finer frequency resolution and the ability to differentiate signals that have frequencies that are closer together.

Why not use the smallest RBW setting for all measurements?

Sweep Time.

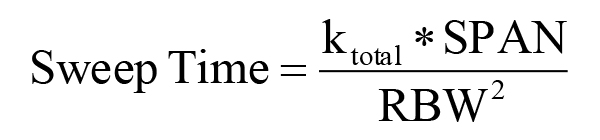

Sweep time is the length of time it takes to sweep the detector from the start to the stop frequency. Here is the equation governing the sweep speed:

In this formula, the meaning of the first factor is the number of frequency selections under SPAN, each step is 1 / k of RBW, to ensure the accuracy of amplitude measurement. The second factor means that each selection The time required depends on the smaller value between RBW and video bandwidth (VBW). Usually when we do not focus on noise, the VBW can be set to a value greater than or equal to RBW.

The time equation is reduced to:

That is to say, the scanning time is proportional to SPAN and is inversely proportional to the square of RBW. This means that if the RBW is reduced by 100 times the scanning time will be increased by 10000 times in the same SPAN

Smaller RBWs also lower the noise floor, but they extended the sweep time for a given span of frequencies. Select a spectrum analyser that has a large number of RBW settings, especially on the lower frequency end. You may not use 10 Hz RBW often, but it is very useful when you do. Adjustment is easy. Simply adjust the RBW to provide the proper balance between speed and resolution for your application.

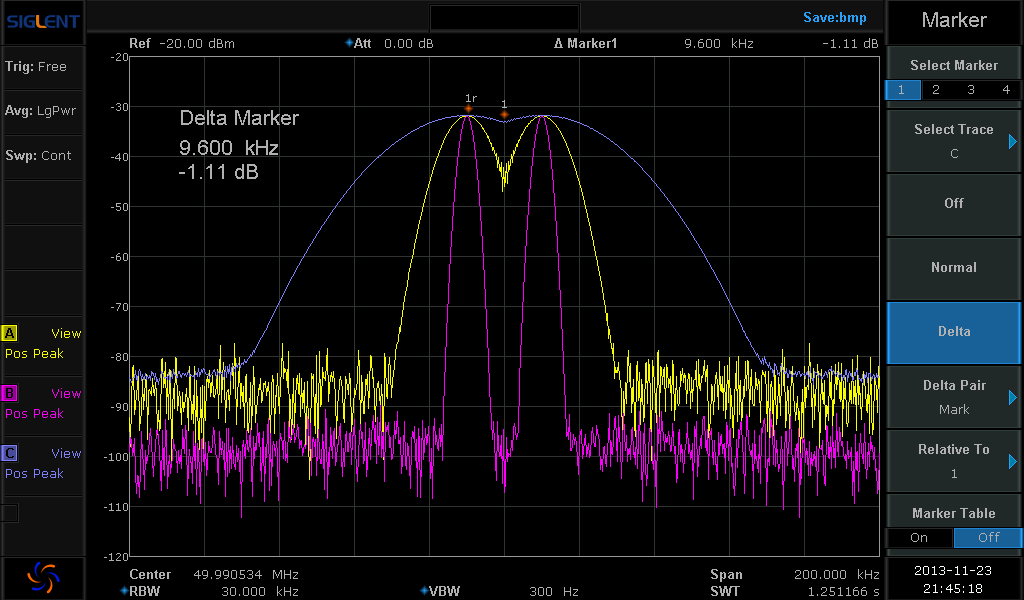

Figure 1 is the measurement of two signals separated by 20 kHz. The traces were collected using RBWs of 30 kHz (Blue), 10 kHz (Yellow), and 3 kHz (Pink). Observer that while the frequency of these two similar signal measurement power is completely unchanged, the signal separation is only clear when the RBW is less than the frequency difference between the signals.

Figure 1: Spectrum analyser display showing two signals at three different resolution bandwidth (RBW) settings.Shape and Shape Factor

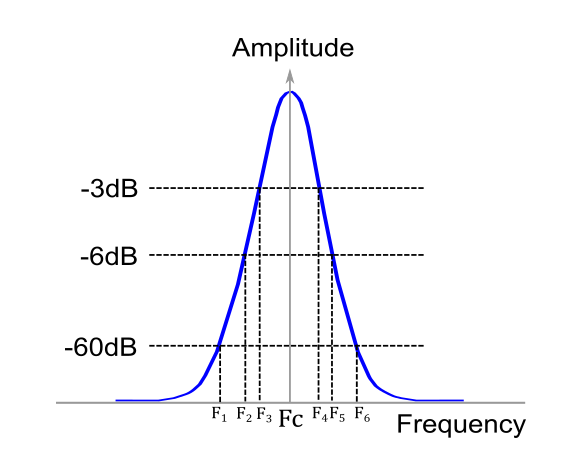

The shape and shape factor of the RBW filter can also be an important selection. Many analysers have an RBW filter that has a Gaussian shape and a shape factor determined at the 3 dB point. The RBW value is the bandpass frequency of the filter 3 dB below the peak response of the filter. Recall that 3 dB is equal to 50% of the maximum. This is also referred to as the filters Full Width Half Max (FWHM) value. The 3 dB Gaussian filter is acceptable for many measurements, but for Electromagnetic Compliance (EMC) related measurements, a filter defined at 6 dB may be required.

The shape factor of a filter is the ratio of the response at two attenuation values. Typically, the highest attenuation is measured at 60 dB down. The lower attenuation value is either or 6 dB down. It is a measure of the sharpness of the filter response. If the ratio is large, the filter is not very “sharp”. This indicates that the filter spreads out over a large frequency range. If the ratio is small, this indicates a skinnier filter shape and sharper roll off. This aids in rejecting more out-of-band signals because they don’t “bleed” over. Figure 2 shows how the shape factors for both the 3 dB and 6 dB points are calculated for a given filter. For spectrum analysers, the 3 and 6 dB shape factors are similar, but the 6 dB filter has a steeper curve and has higher out-of-band rejection.

Shape Factor @ 3/60dB = (F6 – F1)/(F4-F3)

Shape Factor @ 6/60dB = (F6 – F1)/(F5-F2)

Figure 2: Gaussian filter showing 3, 6, and 60 dB points and center Frequency (Fc).Phase Noise

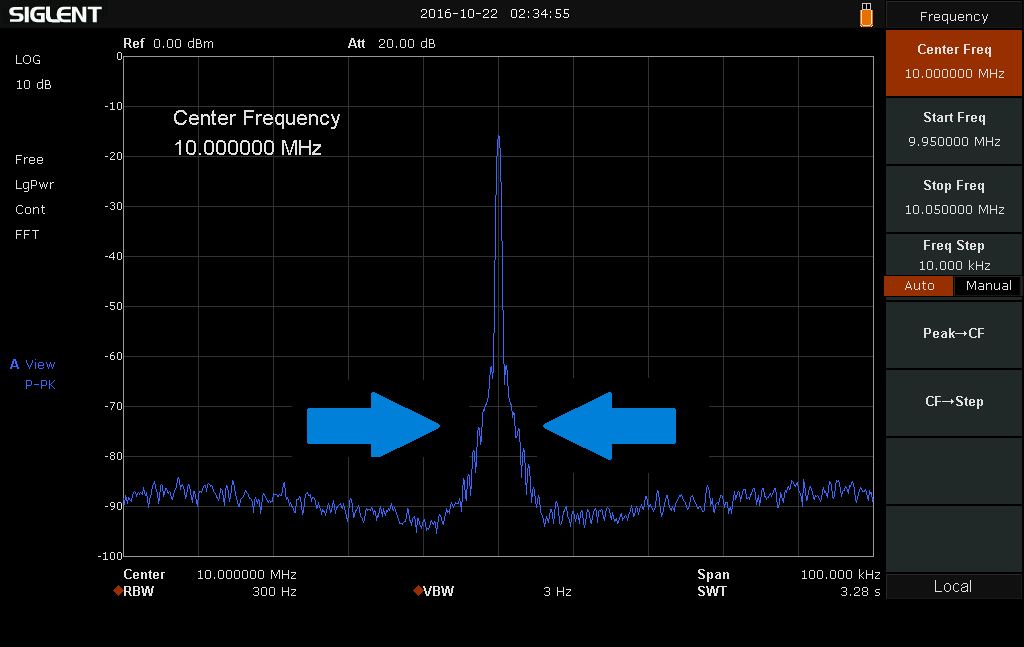

Another factor that affects the frequency resolution of an analyser is the phase noise. This is observed as a widening and increase in the noise amplitude near the center frequency of the signal (figure 3). It is caused by the random thermal fluctuations of the oscillator used as a timing reference in the spectrum analyser circuitry. These fluctuations cause the phase of the output clock signal to vary with time, very similar to jitter in a time-based system. This widening can cover up any small signals that may be near the frequency of interest. For meaningful measurements, select an instrument with lower phase noise than the signal source you are measuring.

Figure 3: Spectrum analyser display showing phase noise effects of an input signalVideo Bandwidth (VBW)

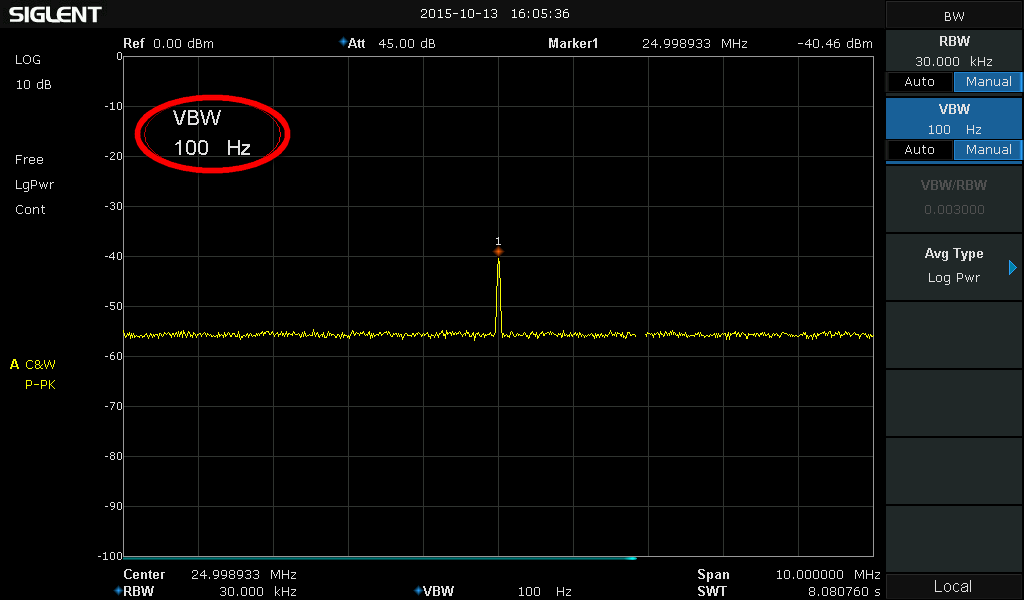

Another factor that affects the displayed trace quality of a spectrum analyser is the video bandwidth (VBW). Video filtering is a time-domain low-pass filter, mathematically equivalent to the mean or average. The main effect of the VBW filter is to smooth the trace and decrease noise.

Strictly speaking, the VBW does not change the measurement results. It will not affect the “frequency selection, peak detection” of the measurement process. The VBW filter is applied after the data has been collected, but before the screen displays the trace. As can be seen from figure 4 below, when the VBW is large, noise makes small signal observation difficult. If we reduce the VBW, the small signal becomes much more clearly.

Figure 2: Smoothing effect of random signal with different VBWConclusions

Modern spectrum analysers offer flexible measurement capabilities. Select an analyser that provides an adjustable RBW/VBW (lower is better), lower phase noise than the signal you are testing. Adjusting the RBW can provide lower noise floor and fine frequency resolution, but the sweep time will increase dramatically. For noisy signals, you can lower the VBW to help smooth the trace and make signal identification easier, but this will also increase sweep time. If you are performing EMI measurements, a 6dB sharper filter option is required to increase peak detection accuracy.

Spectrum Analyser Basics: Detectors

Spectrum analysers like the SIGLENT SSA3000X Series have a number of available detector selections that can help you observe specific signals of interest. This operating tip provides a brief description of the available detector types and suggested usage.

BASICS:

The SIGLENT SSA 3000X Series spectrum analysers normally display power versus frequency on a Cartesian coordinate system as shown below:

The horizontal span (which composes a frequency span when the instrument is configured to sweep/not in zero span mode) is comprised of 751 discrete samples (also called “bins”).

The analyser sweeps from the start frequency to the stop frequency and fills each frequency “bin” with an amplitude value determined by the detector selected for that particular sweep operation.

THE DETECTORS:

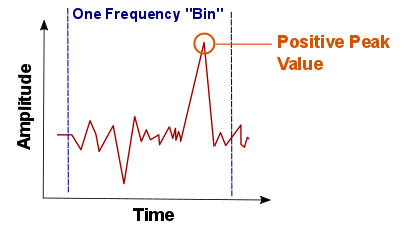

Positive Peak: For each trace point, a Positive Peak detector displays the maximum value of data sampled within the corresponding time interval.

Positive peak detectors are the most commonly used detector type. They are perfect for measuring the peak power of a signal as well as determining the “worst case” signal in EMI applications.

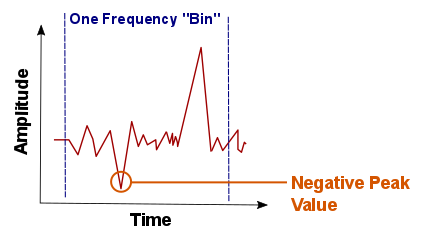

- Negative Peak: For each trace point, a Negative Peak detector displays the minimum value of data sampled within the corresponding time interval.

Negative peak detectors are rarely used, but can be helpful when comparing positive and negative peak values when looking for CW and Pulsed signals. CW signals will have less difference between positive and negative peak values for a given frequency bin. A pulsed signal could have a significant difference

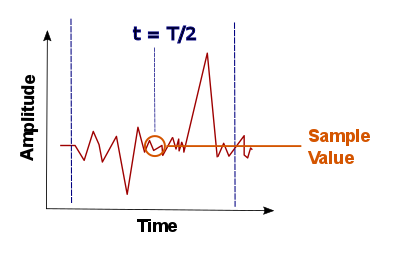

- Sample: For each trace point, a Sample detector displays the transient level corresponding to the central time point of the corresponding time interval.

This detector type is applicable to noise, noise-like signals, or small amplitude continuous wave (CW) signals that are near the noise floor of the analyser.

- Normal: Normal detector (also called rosenfell detector) displays the maximum value and the minimum value of the sample data segment in turn; namely for an odd-numbered data point (bin), the maximum value (positive peak) is displayed; for an even-numbered data point (bin), the minimum value is displayed. In this way, the amplitude variation range of the signal is clearly shown.

- Average: For each trace point, an Average detector displays the average value of data sampled within the corresponding time interval.

- Quasi-Peak (QP): This is a mathematically weighted form of the positive peak detector. For a single frequency point, the detector measures the peaks within the defined detector dwell time. These peaks are then weighted using a mathematical model that simulates a tank circuit that meets charge/discharge rates specified by CISPR (an international organization that governs electromagnetic effects). The measurement time for QPD is far longer than Peak Detector.

For a given signal, the QP detector values will never be greater than the positive peak results.

Electromagnetic Compliance: Measuring Conducted Noise with a Tekbox LISN

Our friends at Tekbox have a nice app note that provides details on performing conducted noise measurements using a SIGLENT SSA3000X Spectrum Analyser:

DIY Spectrum Analyser Input Protection

Spectrum analysers like the SIGLENT SSA3000X and SVA1000X series are extremely useful instruments that can provide invaluable insight into broadcast signal performance, transmitter troubleshooting, and interference as well as RF device characterization and EMC testing.

But, like other spectrum analysers, they are very sensitive and can be damaged easily, if the proper precautions are not followed.

The instruments have standard protection elements that includes a DC blocking capacitor and an automatic attenuator that help to prevent damage from low frequency and higher powered signals. There is even an audible and visible warning if the ADC (Analog-to-Digital Converter) overload.

In addition to this, adding external attenuation and protection can be useful in further preventing damage, especially when connecting to unknown sources such as antennas, transmitters, and LISNs.

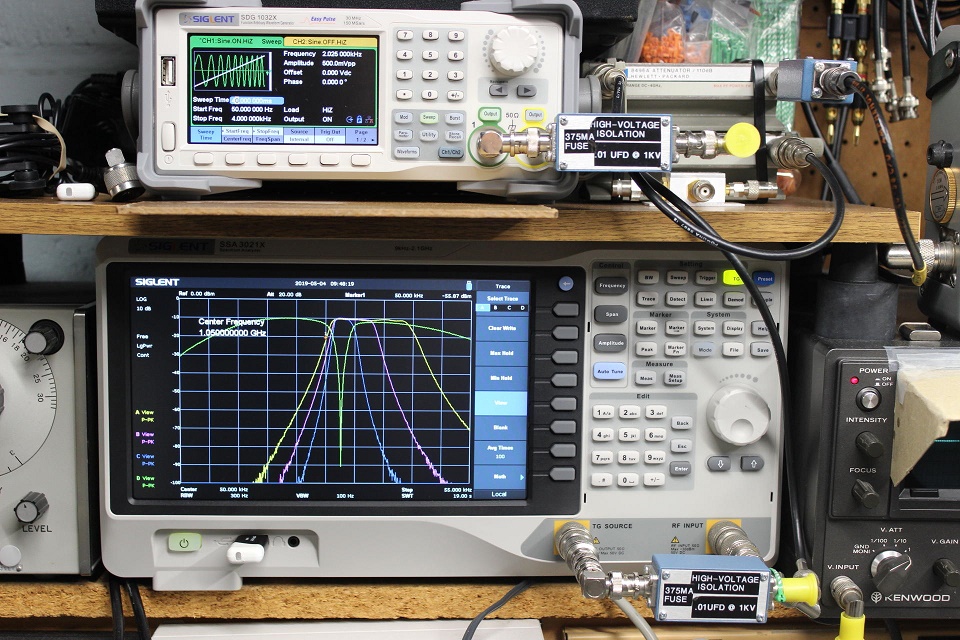

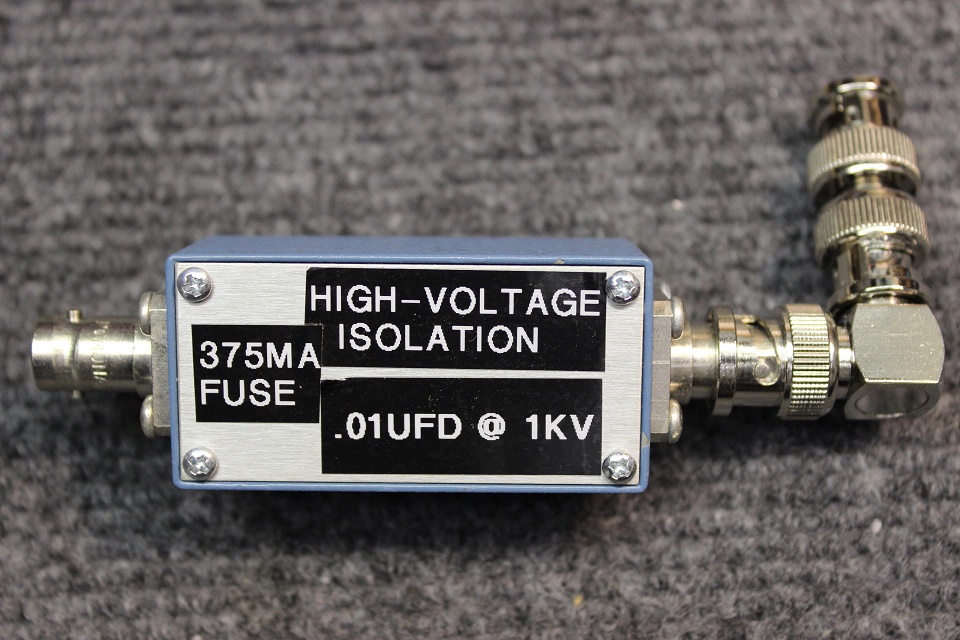

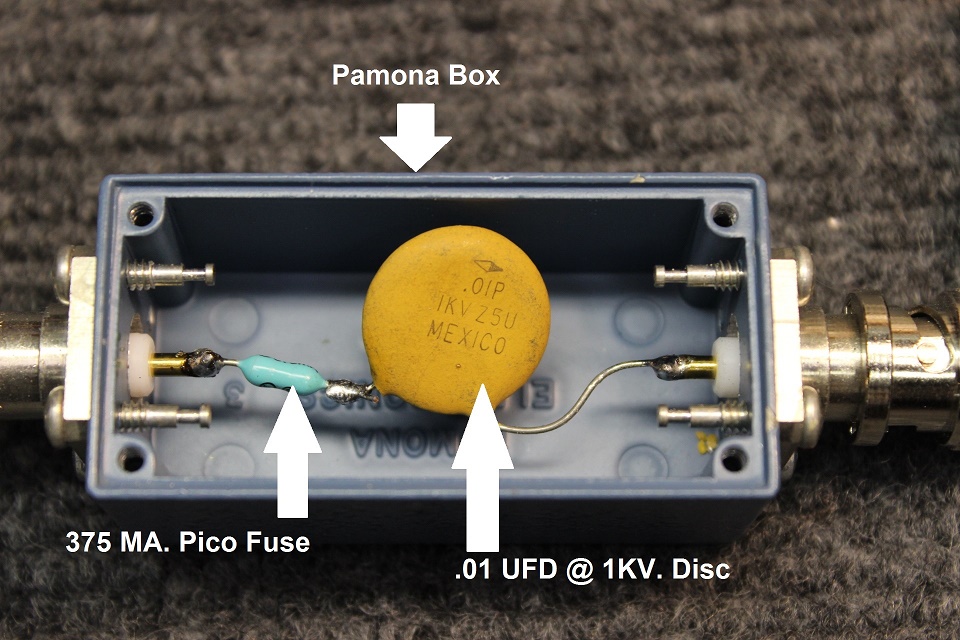

One of our customers, Mr. Jeff Covelli (WA8SAJ), is a HAM (Amateur Radio Operator) who recently shared a very simple protection box that can be useful for keeping that sensitive front end functioning when connecting to unknown signal sources.

He uses it to help protect the input on his SIGLENT SDG1032X signal generator as well as his SSA3021X spectrum analyser:

And he has a pretty impressive setup:

And here are the details:

At some point, I hope to characterize this setup and provide S11, S21 information.. but, if your signal is unknown, this will add an additional layer of protection when measuring an unknown signal for the “first time”.

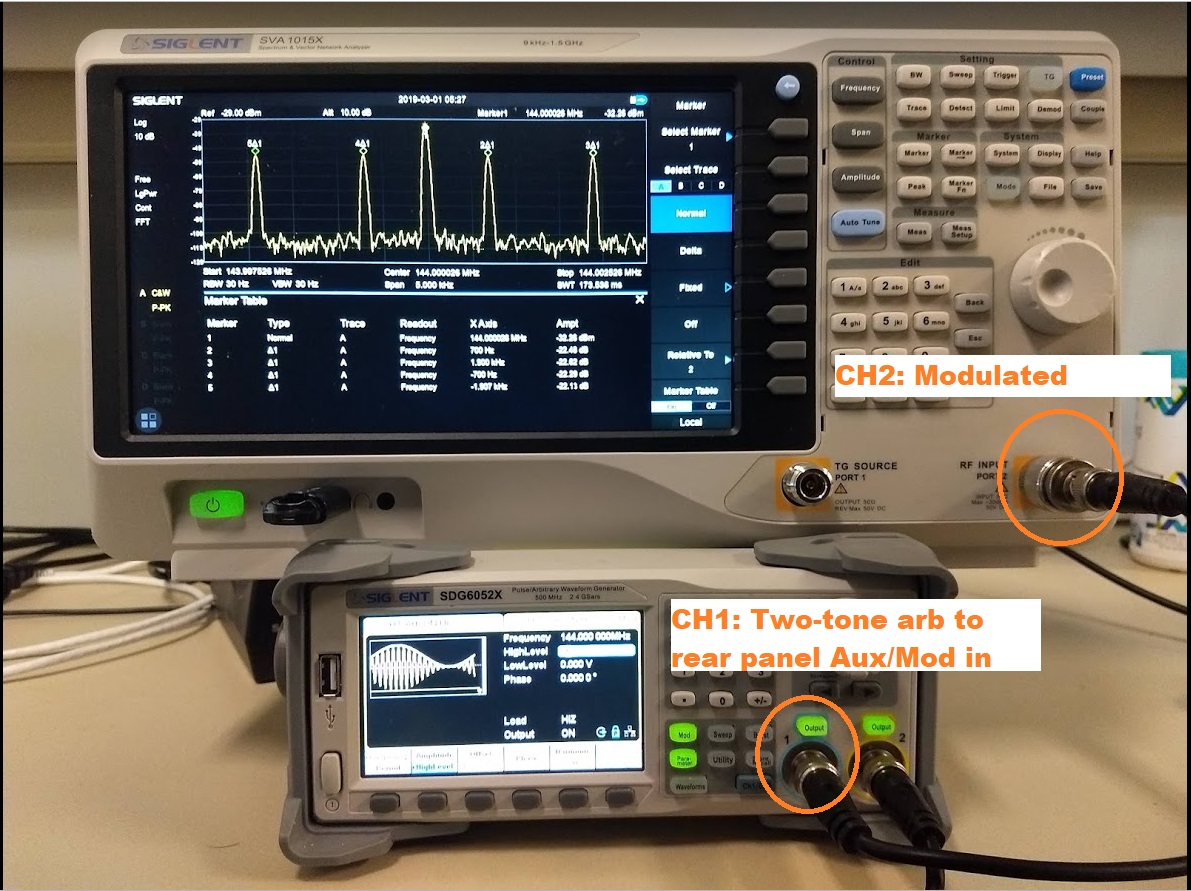

Two-tone testing: Building an arbitrary waveform using the Equation Draw function

In this note, we are going to use Equation Draw within EasyWave to create a waveform that is built using the addition of sine waves with two different frequencies (700 and 1900 Hz). We will then show how to use this signal to modulate a carrier up-to 500 MHz using the other SDG output channel.

EasyWave is free software designed to help create and edit arbitrary waveforms and download them to applicable SIGLENT SDG series of arbitrary waveform generators, including the SDG800, 1000, and X series. You can download it here: EasyWave

EasyWave has an interesting feature called Equation Draw that enables you to create complex waveforms using some common basic math and trigonometric functions, like +, -, *, /, sine, cosine, and more.

NOTE: Two-tone testing is commonly used to test the performance of audio data that is embedded in modulated signals like AM or FM radio broadcasts. You can use two-tone signals to check the performance of RF receivers. The ARRL and other radio-centric organizations have lots of data on testing receivers, for those so inclined.

Many of the SDG products have a wave combine feature that mathematically adds the waveforms for both channel 1 and channel 2. This is technically easier than the process we highlight in this note, but it requires the use of both channels of the SDG. The using a single output arbitrary waveform allows us to use the other free channel for other tasks, including sourcing a carrier modulated by our two-tone signal (see the end of this note for more info).

To learn about Wave Combine, click here: Wave Combine

Setup

- SIGLENT SDG arbitrary waveform generator (We are using an SDG6052X capable of 500 MHz for this note)

- EasyWave software

- USB or LAN connection

Before beginning, please install EasyWave (The instructions are available with the download available here: SDG Software Downloads) and connect the instrument to the computer.

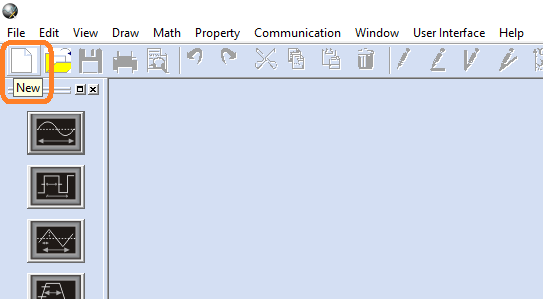

- Open EasyWave by double-clicking on the EasyWave Icon:

2. Open a new waveform:

3. Name the waveform (optional) and set the frequency of the main repeated waveform. In this case, we will set the Frequency to 100 Hz. Press OK:

NOTE: The arbitrary waveform “frequency” is the repetition frequency of the entire waveform loaded into memory. If that waveform has a single period, then the set frequency here will be the frequency of the output waveform. If the waveform has 2 periods, then this frequency will be half of the actual waveform frequency (because there are 2 periods per memory “frame”). In this process, the frequency set in this step is equal to the “X” variable used in future steps.

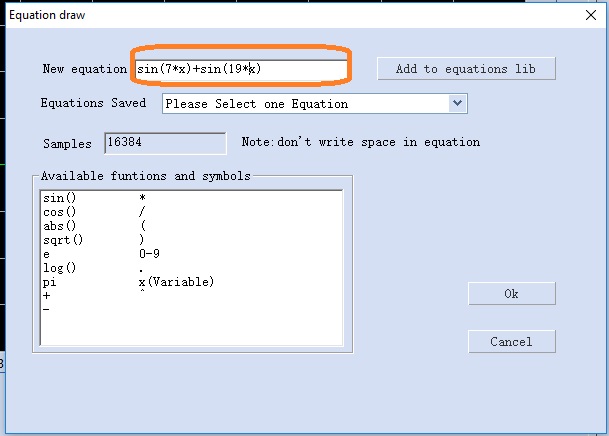

4. This opens the wave1 waveform window. Now, click on the Equation Draw icon to open the equation editor. This includes a listing of available math elements as well as a saved equations area.

For this example, we want two tones… one at 700 Hz and the other at 1900 Hz. Since we set the output frequency to 100 Hz (remember we named that “X” above), we can simply enter our equation in the New Equation field using standard trigonometric functions as shown:

y(x) = sin(7*x) += sin(19*x)

Press OK to enter.

NOTE: This will create a waveform that is the addition of two sine waves. One with a frequency 7 times X (7*100 Hz = 700 Hz) and the other with a frequency 19 times X (19*100 Hz = 1900 Hz).

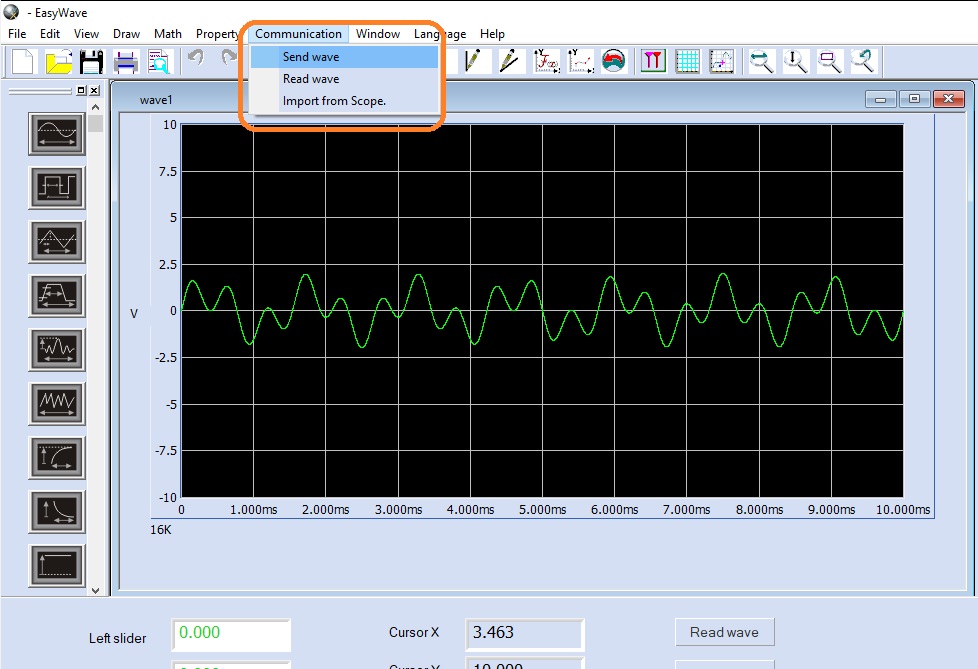

Now, the wave window shows a green waveform that represents the waveform we entered via the Equation Draw method. Confirm that it matches your expectations for your application.

5. Press Communication to open the dialog to begin downloading the waveform to the instrument:

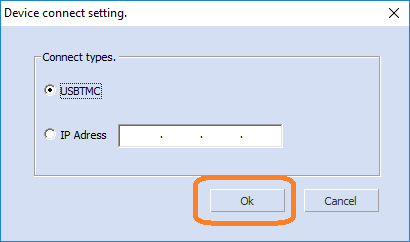

6. Select the connection type (USB = USBTMC) and press OK

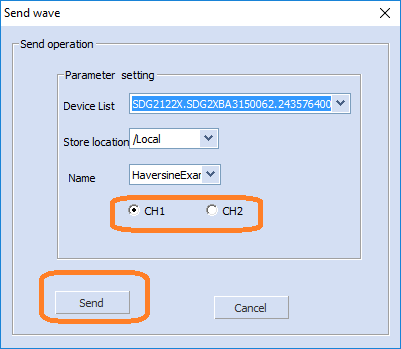

7. Select the correct USB device, Waveform Name, and Channel.. press OK:

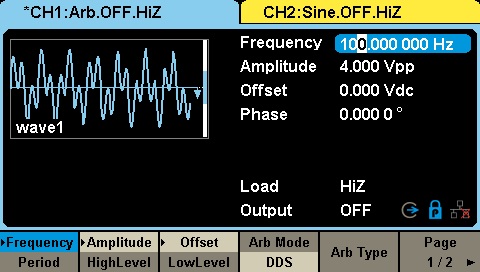

8. Now, you can observe the waveform and parameters on the display of the generator. Here, you can change the base frequency, amplitude, and other waveform characteristics.

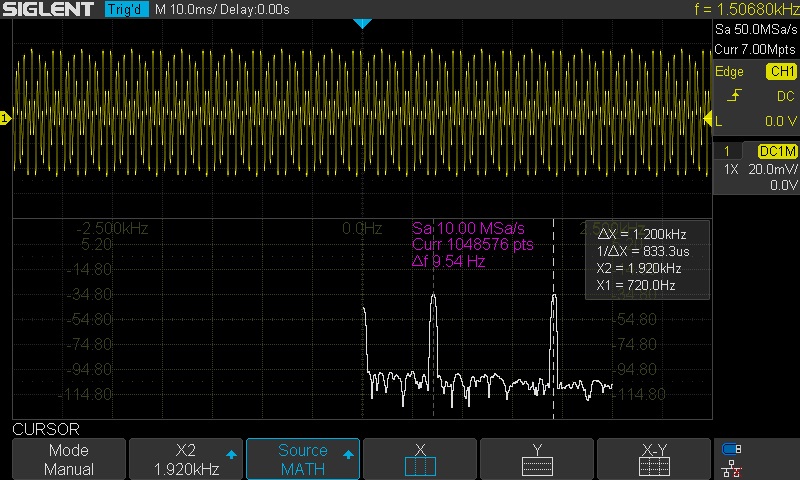

Here is a screen capture of an oscilloscope using the FFT function to capture the spectral content of the output using the waveform created:

Note that the frequency markers show peaks at 700 and 1900 Hz, as expected.

Next Step: Source a two-tone modulated carrier

Now that we have verified the two-tone output, we can use this waveform as a modulation source for a higher frequency carrier. This modulated signal can be used to test the performance of a receiver.

Here are two options for creating a modulated carrier:

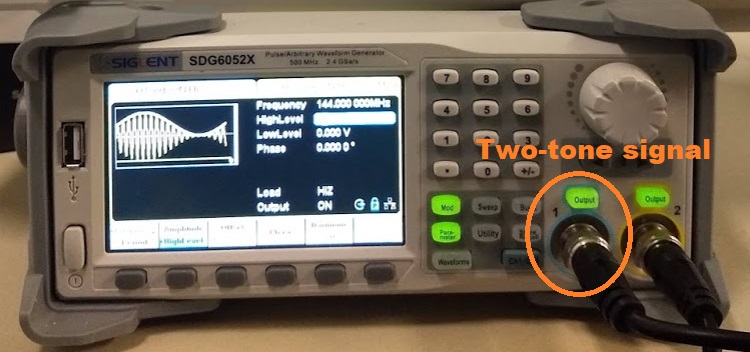

SDG External Modulation for carriers < 500 MHz

Many SDG generators include an external modulation input which can be used to modulate the output of a specified channel. In this example, we can simply route the two-tone channel to the external modulation input. Then, configure the other channel to output a modulated carrier.

Here, we will use the SDG6052X, which can output sine waves up to 500MHz. As mentioned previously, this technique works with any dual channel SDG. When selecting a generator, remember that the maximum carrier output frequency includes the modulation bandwidth. If your generator has a maximum frequency of 100 MHz and the modulation bandwidth is 10 kHz, then the maximum carrier frequency when modulation is active will be 100 MHz – 10 kHz/2.

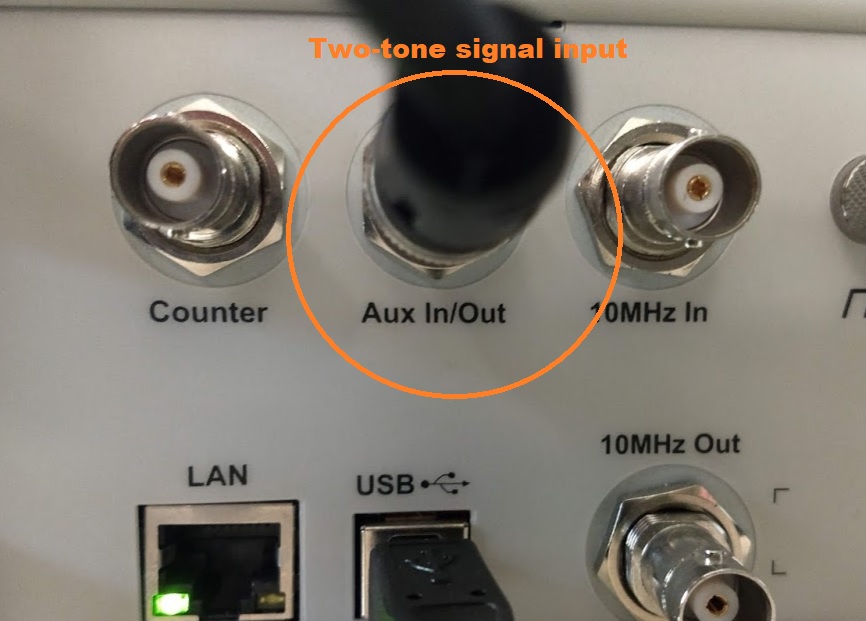

- Route a cable from the two-tone channel to the Aux In located on the rear panel. In this case, channel 1 is the two-tone source:

Front Panel:

Rear Panel:

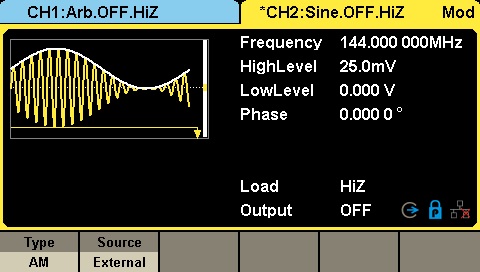

- Configure the other channel as the modulated carrier (channel 2, in this example) for external modulation by pressing Mod and configuring the channel as shown.

Here, we set the channel to use the external input to modulate an AM carrier with a frequency of 144 MHz, in the amateur radio broadcast 2m band :

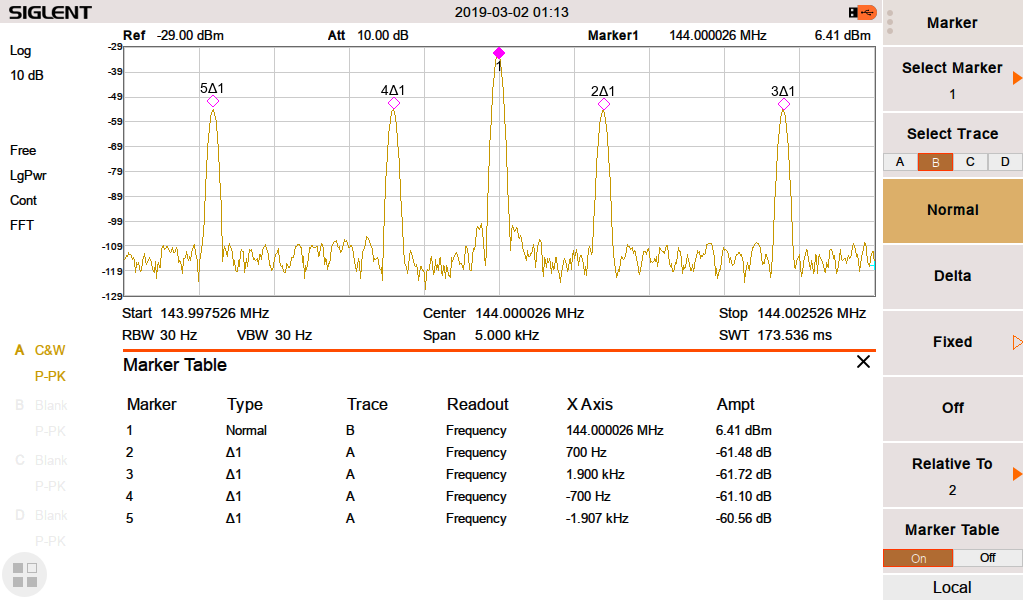

Now, we can confirm the output using a spectrum analyser.

Here, we connect the modulated carrier output (channel 2) into a SIGLENT SVA spectrum analyser:

Here, you can see the carrier at 144 MHz, and the two tones at +700, +1900, -700, and +1900 Hz from the carrier.. as expected.

NOTE: Make sure that the output power of your SDG is low enough to prevent damage to the spectrum analyser or add enough external attenuation to make sure you don’t damage the input.

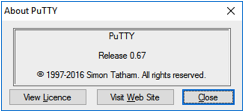

Testing Open Socket Communications Using PuTTY

Many instruments include the ability to be controlled via a remote connection to a computer using an Ethernet connection. In many cases, these instruments require a special software library that can help establish and maintain the communications link between the instrument and controlling computer. This can be annoying for a few reasons… the software library is likely to occupy a large amount of space on the controlling computer and is also required on any computer that is being used to control the instrument. In a remote networking application where multiple user’s may want access to a test instrument, this can cause support and installation headaches.

Luckily, there are a few solutions that can help. In this application note, we are going to discuss using open socket communication techniques using an open source communication tool called PuTTY with a SIGLENT SSA3032X spectrum analyser.

What are open sockets and why use them?

Within the context of Ethernet/LAN connections, sockets are like mailboxes. If you want to deliver information to a specific place, you need to be sure that your information is delivered to the correct address.

In the context of test instrumentation, an open socket is a fixed address (or port number) on the Ethernet/LAN bus that is dedicated to process remote commands.

Open sockets allow remote computers to simply use existing raw Ethernet connections for communications without having to add additional libraries (VISA or similar) that require additional storage space and processing overhead.

Programs that utilize sockets for LAN communication tend to take up less memory and operate more quickly.

PuTTY

PuTTY is an open source software tool that provides a number of simple communication links (RAW, Telnet, SSSH, Serial, and others). It is available for free and there are a number of versions available for popular operating systems.

You can download as well as learn more here: https://www.putty.org/

In this example, we are using PuTTY to verify the raw LAN connection is working properly. It is quite a simple program that does not allow for very complex operation (sequences, converting data sets/strings, etc..). If you require more complex functionality, software platforms like Python, .NET, C#, LabVIEW, etc.. can be used to control the instrument using a similar open socket connection.

Configuration

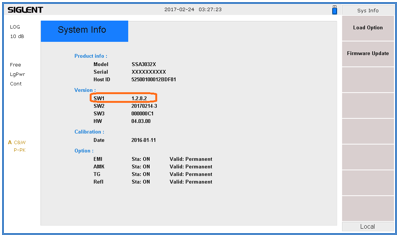

In this test, we are using the most current revision of the SIGLENT SSA3032X Spectrum Analyzer firmware (Revision 01.02.08.02) which enables open socket communication.

This example also uses PuTTY version 0.67:

Steps

1. Install PuTTY for the OS you intend to use

2. Make sure your instrument and firmware revision can use open sockets

The SSA3032X revision 01.02.08.02 enables open socket communication.

To find the revision, press the System button > Sys Info.

Figure 1 below shows a sample system information screen from a SIGLENT SSA3000X analyzer:

Figure 1: Sample system information page from an SSA3000X.Check the product page and firmware release notes for more information.

3. Connect the instrument to the local area using an Ethernet cable

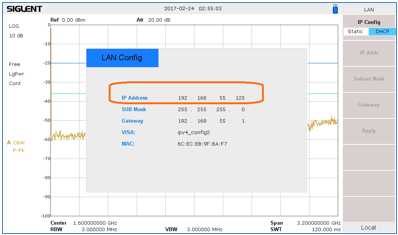

4. Find the IP address for the instrument. This is typically located in the System Information menu. On the SIGLENT SSA3032X, press the System button on the front panel > Interface > LAN.

Figure 2 below shows a sample LAN setup page from a SIGLENT SSA3000X:

Figure 2: Sample LAN information page from an SSA3000X.5. Open PuTTY

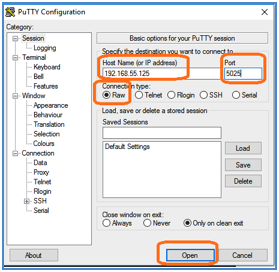

6. Select Raw as connection type

7. Enter the IP address in the Host Name field

8. Enter the port number. This should be provided in the users or programming guide for the instrument.

The SIGLENT SSA3000X uses port 5025.

Figure 3 below shows the PuTTY configuration for this example:

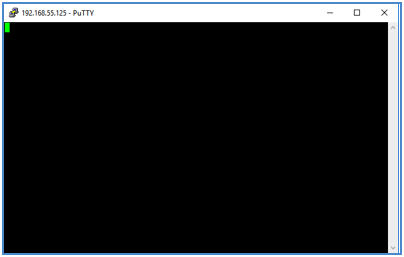

Figure 3: Example PuTTY configuration.9. Press Open. This will open a terminal window as shown in below:

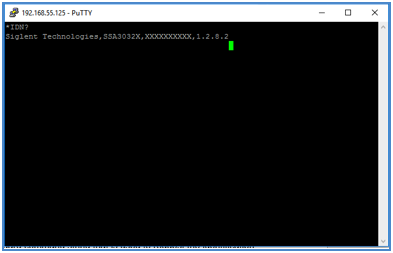

10. Using the computer keypad, enter *IDN? and press the Enter key on the keyboard to send the command.

This is the standard command string that is used to request the identification string from the instrument. As shown below, the instrument responds with the manufacture, product ID, Serial Number, and firmware revision.

Conclusion

PuTTY is an easy way to verify an operational LAN connection to instrumentation that can use open sockets.

Verification of a LAN connection using Telnet

Automating a test can dramatically increase the productivity, throughput, and accuracy of a process. Automating a setup involves connecting a computer to the test instrumentation using a standard communications bus like USB or LAN and then utilizing code entered via a software layer (like LabVIEW, .NET, Python, etc..) to sequence the specific instrument commands and process data.

This process normally goes quite smoothly, but if there are problems, there are some basic troubleshooting steps that can help get your test up-and-running quickly.

In this note, we are going to show how to use Telnet to test the communications connection between an instrument and a remote computer using a LAN connection to ensure that it is working properly. Once the connection is verified, you can begin to work on the control software.

Telnet provides a means of communicating over a LAN connection. The Telnet client, run on a LAN connected computer, will create a login session on the instrument.

NOTE: The Telnet connection requires open sockets on the instrumentation. At this time, not all SIGLENT products feature open sockets. Check the product page FAQs or with your local SIGLENT support office for more information.

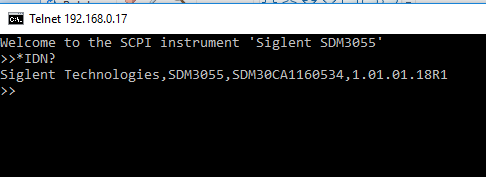

A connection, established between the computer and instrument, generates a user interface display screen with SCPI> prompts on the command line.

Using the Telnet protocol to send commands to the instrument is similar to communicating with USB. You establish a connection with the instrument and then send or receive information using SCPI commands. Communication is interactive: one command at a time.

The Windows operating systems use a command prompt style interface for the Telnet client.

STEPS

1. Power on and connect the instrument to the network via LAN

2. Verify that the Gateway, Subnet Mask, and IP address of the instrument are valid for the network you wish to use. This information is typically located in the System Information or IO menu. See the specific instrument user’s guide for more information on LAN settings.

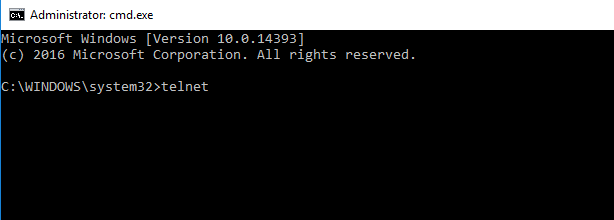

3. On the computer, click Start > All Programs > Accessories > Command Prompt.

4. At the command prompt, type in telnet.

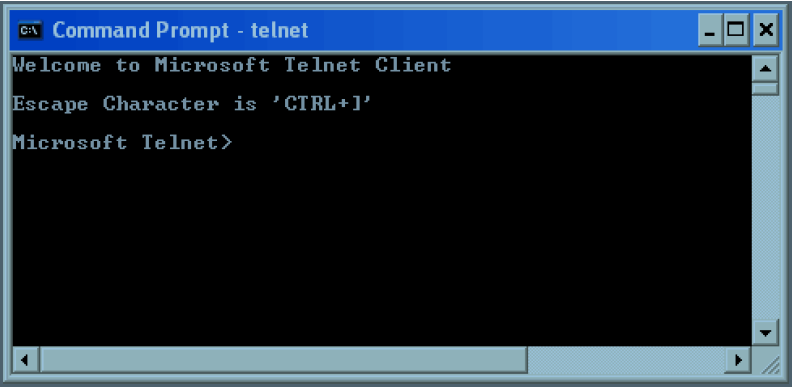

5. Press the Enter key. The Telnet display screen will be displayed.

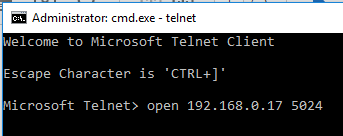

6. At the Telnet command line, type: open XXX.XXX.XXX.XXX 5024 where XXX.XXX.XXX.XXX is the instrument’s IP address and 5024 is the port. You should see a response similar to the following:

7. Now, you can enter any valid command for the specific instrument that you are controlling. See the specific programming guide for the instrument for more information.

This is especially helpful when you are planning a specific test sequence, the effect of delays/timing, or troubleshooting a command. You can send each command one-at-a-time and check the performance of the instrument.

*IDN? is a common identification string query (question or information request) that returns the information from the connected instrument

Programming Example: Open Socket LAN connection using Python

Automating a test can dramatically increase the productivity, throughput, and accuracy of a process. Automating a setup involves connecting a computer to the test instrumentation using a standard communications bus like USB or LAN and then utilising code entered via a software layer (like LabVIEW, .NET, Python, etc..) to sequence the specific instrument commands and process data.

In this note, we are going to show how to use Python to create a communications link between an instrument and a remote computer using a LAN connection. Once the connection is verified, you can begin to work on the control software.

NOTE: This example requires open sockets on the instrumentation. At this time, not all SIGLENT products feature open sockets. Check the product page FAQs or with your local SIGLENT support office for more information.

Python is an interpreted programming language that lets you work quickly and is very portable. Python has a low-level networking module that provides access to the socket interface. Python scripts can be written for sockets to do a variety of test and measurements tasks.

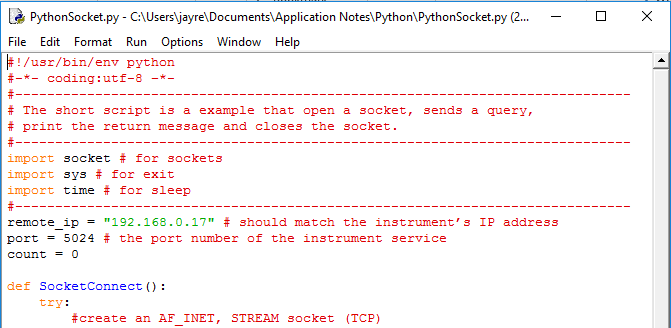

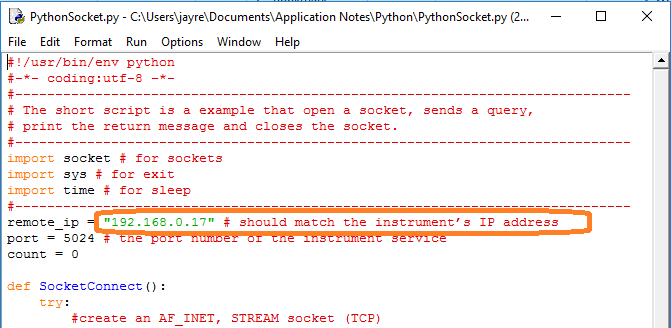

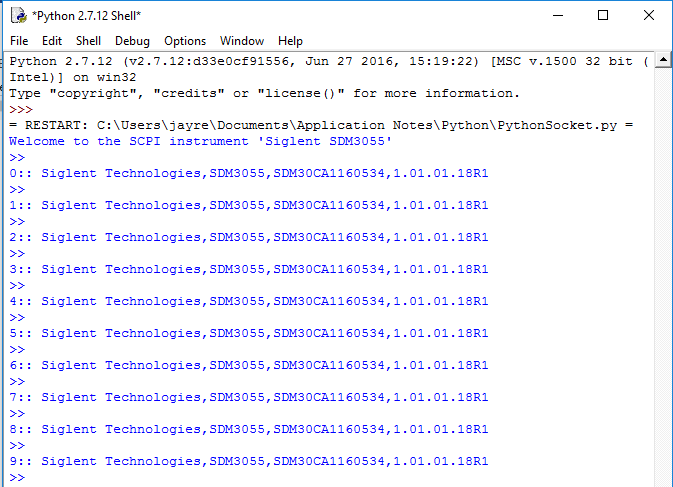

Here is a Python 2.7 script that opens a socket, sends a query and closes the socket. It performs this operation in a loop 10 times:

You can follow the instructions below to build your own example:

1. Power on and connect the instrument to the network via LAN

2. Verify that the Gateway, Subnet Mask, and IP address of the instrument are valid for the network you wish to use. This information is typically located in the System Information or IO menu. See the specific instrument user’s guide for more information on LAN settings.

3. Download python and your favourite python editor (I use IDLE):

https://docs.python.org/2/library/idle.html

Start your python editor:

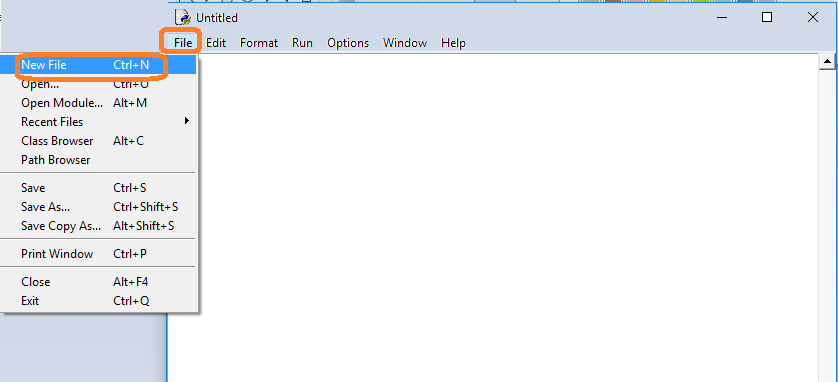

5. Open a new file by pressing File > New File.. and name the file

6. Copy and paste the code at the end of this note into the file editing window:

7. Change the IP address and port number so that they match the IP address and port for the instrument you wish to connect to:

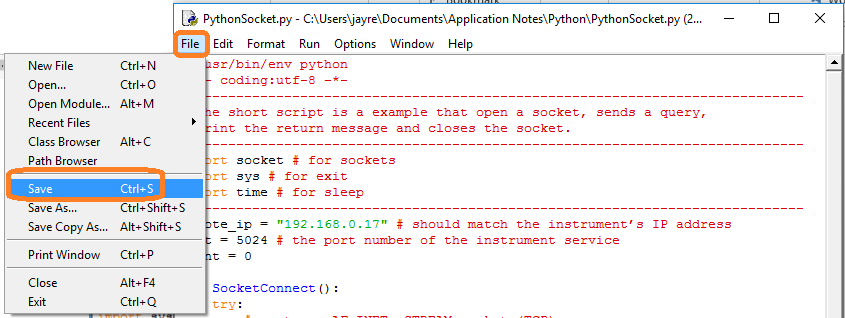

Save the file:

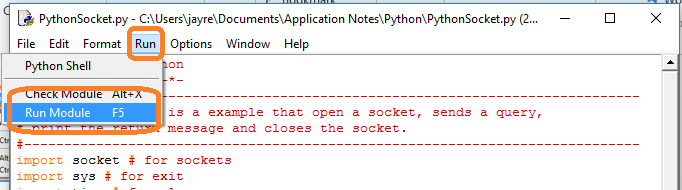

8. To Run, select Run and Run Module:

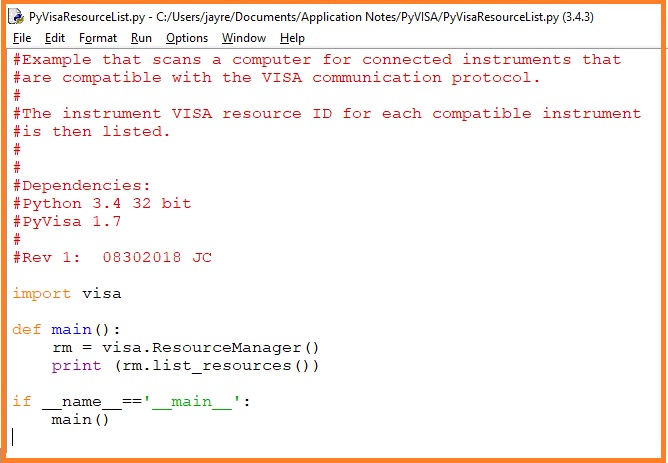

Programming Example: List connected VISA compatible resources using PyVISA

PyVISA is a software library that enables Python applications to communicate with resources (typically instruments) connected to a controlling computer using different buses, including: GPIB, RS-232, LAN, and USB.

This example scans and lists the available resources.

It requires PyVISA to be installed (see the PyVISA documentation for more information)

***

#Example that scans a computer for connected instruments that

#are compatible with the VISA communication protocol.

#

#The instrument VISA resource ID for each compatible instrument

#is then listed.

#

#

#Dependencies:

#Python 3.4 32 bit

#PyVisa 1.7

#

#Rev 1: 08302018 JCimport visa

def main():

rm = visa.ResourceManager()

print (rm.list_resources())if __name__==’__main__’:

main()

*****

Here is the code:

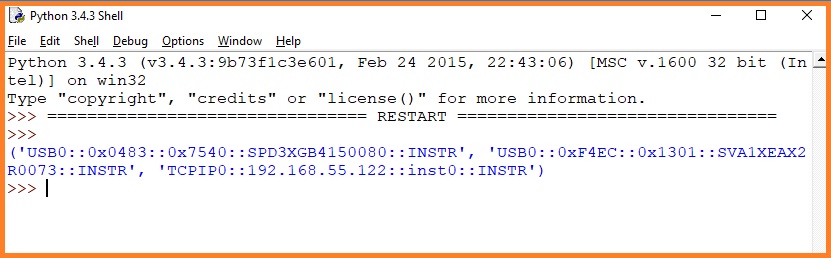

And here is the result of a scan:

Each connected instrument returns a specific formatted string of characters called the VISA Resource ID.

The resource ID format is as follows:

‘Communication/Board Type (USB, GPIB, etc.)::Resource Information (Vendor ID, Product ID, Serial Number, IP address, etc..)::Resource Type’

In the response, each resource is separated by a comma. So, we have three resources listed in this example:

‘USB0::0x0483::0x7540::SPD3XGB4150080::INSTR’ – This is a power supply (SPD3X) connected via USB (USB0)

‘USB0::0xF4EC::0x1301::SVA1XEAX2R0073::INSTR’ – This is a vector network analyzer (SVA1X) connected via USB (USB0)

‘TCPIP0::192.168.55.122::inst0::INSTR’ – This is an instrument connected via LAN using a TCPIP connection at IP address 192.168.55.122

Where is the MAC address information for SSA3000X, SSA3000X Plus, SSA3000X-R, and SVA1000X?

The MAC address can be found on the LAN config interface.

Path: System–interface–LAN.