Your cart is currently empty!

Category: Knowledge Base SDS1000X-E Series

Verification of a working remote communications connection using NI – MAX

Automating a test can dramatically increase the productivity, throughput, and accuracy of a process. Automating a setup involves connecting a computer to the test instrumentation using a standard communications bus like USB or LAN and then utilizing code entered via a software layer (like LabVIEW, .NET, Python, etc..) to sequence the specific instrument commands and process data.

This process normally goes quite smoothly, but if there are problems, there are some basic troubleshooting steps that can help get your test up-and-running quickly.

In this note, we are going to show how to use NI-MAX to test the communications connection between an instrument and a remote computer using both a USB and a LAN connection to ensure that they are working properly. Once the connection is verified, you can begin to work on the control software.

National Instruments Measurement and Automation Explorer (NI-MAX) is a free communications tool provided with NI’s VISA library.

You can learn more here: https://digital.ni.com/public.nsf/allkb/71544521BDE34FFB86256FCF005F4FB6

USB Connections

1. Power on and connect the instrument via USB cable to the computer. On a computer running Windows, the first time you connect the USB from an instrument should open a dialog box or show a notification of a new device being connected.

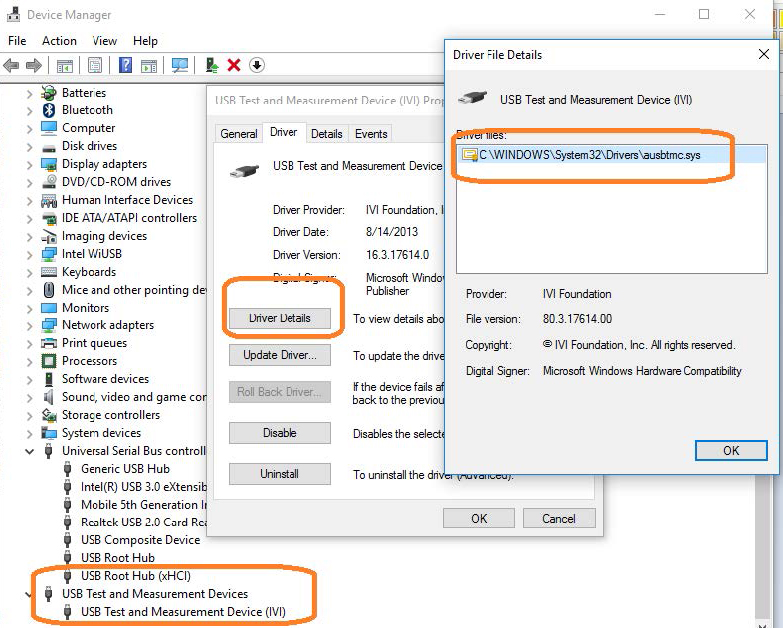

You can check the status of the USB connections by opening Device Manager located in the Control Panel menu of most Windows Operating systems and expanding the driver information as shown below in this Windows 10 example:

This indicates that the operating system recognizes the connected instrument as a test instrument.

If the device manager reports the USB connection as some other type of device (printer, camera, unknown, etc.), there is likely a problem linking the proper driver (ausbtmc.sys) to the instrument. One possible solution to this is to disable the driver, disconnect the USB cable, verify that ausbtmc.sys exists, and then reconnect the USB cable.

2. Run NI-MAX by left-clicking on the icon on the desktop or finding it via the start menu

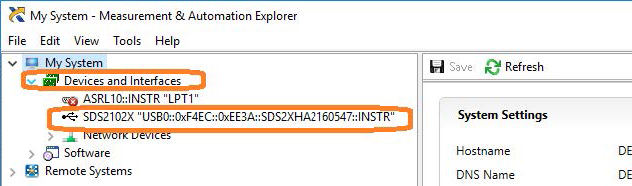

3. This will open the main window, as shown below:

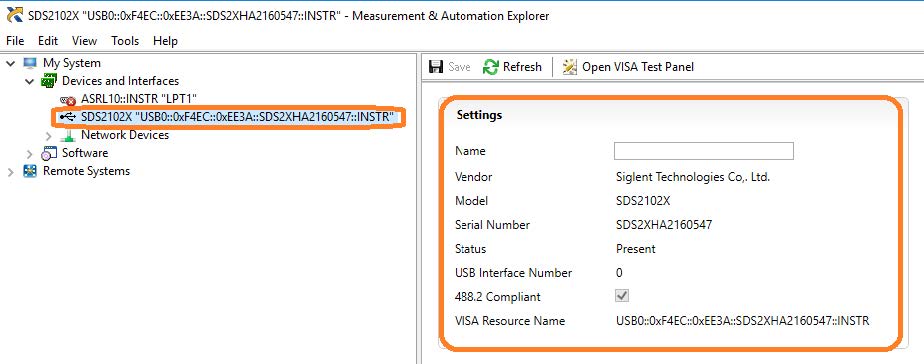

4. Expand the “Devices and Interfaces” menu. You should see the instruments attached via USB with a brief description as shown for an SDS2000X oscilloscope below:

This indicates that a software application (NI-MAX) has correctly identified a test and measurement device (the oscilloscope) over the USB connection.

5. By left-clicking on the instrument, you can see additional information about it:

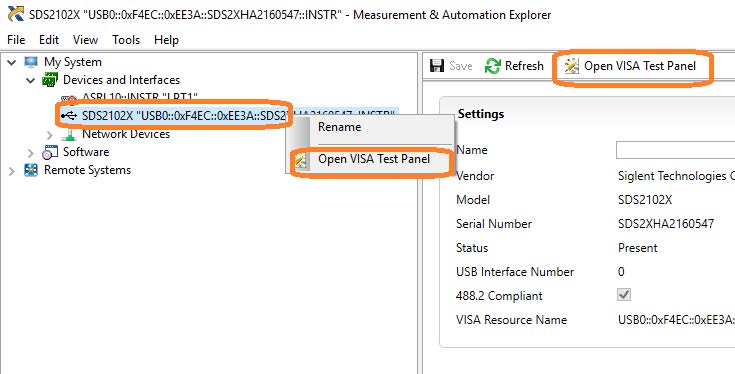

6. To further test the connection, right-click on the instrument and select Open VISA Test Panel or select it from the side bar:

The VISA Test Panel window shows some helpful information, including the instrument manufacturer, model, serial number, and the USB identifier (VISA Address) along the top.

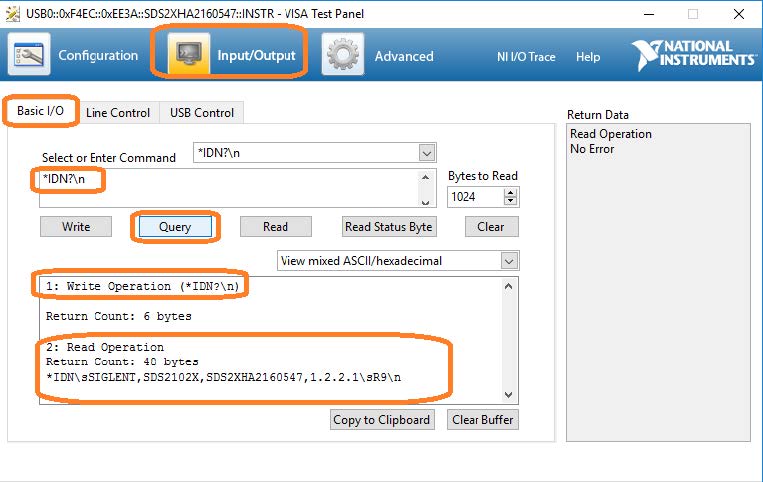

7. Another useful item in the VISA Test Panel is the Input/Output function. This mode allows you to send specific instrument commands and receive instrument responses.

This is especially helpful when you are planning a specific test sequence, the effect of delays/timing, or troubleshooting a command. You can send each

command one-at-a-time and check the performance of the instrument.Select Input/Output > Basic I/O > and Enter the command in the text window:

– *IDN? is a common identification string query (question or information request) that returns the information from the connected instrument

– /n is a termination character that represents a new line. This is the standard termination character for SIGLENT instrumentation.

– Write will send the command to the instrument

– Read will pull data from the instrument

– Query will perform a read and then a write command to request and return data from the instrument

USB Checklist

– Is the USB port configured properly on the instrument? Some instruments feature USB ports that can be configured as TMC (Test and Measurement) or Printer communication ports. The USB port should be set to USBTMC or similar for remote control.

– Try a direct connection to the controlling computer. USB hubs or long connections may cause issues.

– Try a different USB cable. Connectors can go bad or prove to be faulty.

– Try a different USB port on the computer.

– On machines running Windows, check the Device Manager. Test instrumentation should appear as USB Test and Measurement Device (IVI) and use the AUSBTMC.SYS driverLan Connections

1. Power on and connect the instrument via LAN cable to a LAN network connected to the computer you wish to use.

You can check the status of the LAN connection by using a software tool like NMAP: https://nmap.org/

NMAP allows you to scan networks and identify IP addresses.

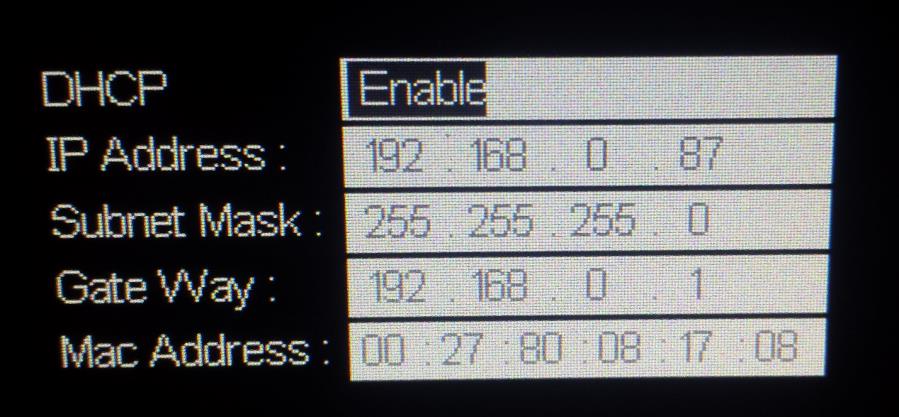

First, identify the LAN connection for the instrument. This is typically located in the System menu under IO or LAN settings.

Here is the IO information for an SDS2000X oscilloscope:

DHCP Enabled will automatically configure the instrument connection settings and apply a valid IP address. With DHCP enabled, the IP address may change over time. It is recommended to check the instrument IP address and then confirm that it is visible on the network using NMAP:

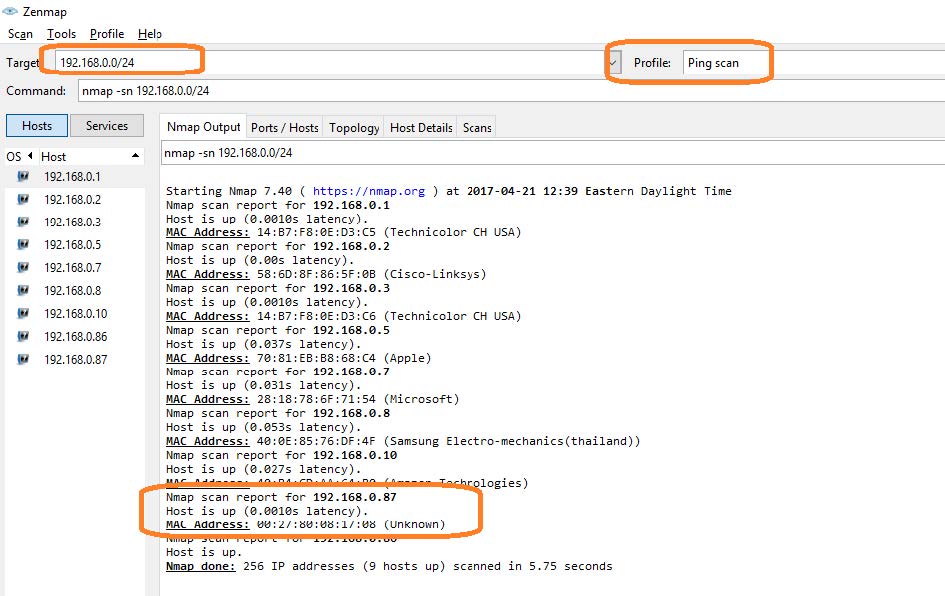

Here, we are performing a Ping (short scan to identify what IP addresses are being used) over the range of IP addresses that may match the instrument.

This can be performed by setting the target using the “/24” extension. This scans 24 bits For example, 192.168.10.0/24 would scan the 256 hosts between

192.168.10.0 and 192.168.10.255Here is more information from NMAP:

https://nmap.org/book/man-target-specification.htmlFor example, to ping all IP addresses that start with 192.168.0., set the target as follows:

Note the IP address and MAC address that identify your instrument.

2. Run NI-MAX by left-clicking on the icon on the desktop or finding it via the start menu

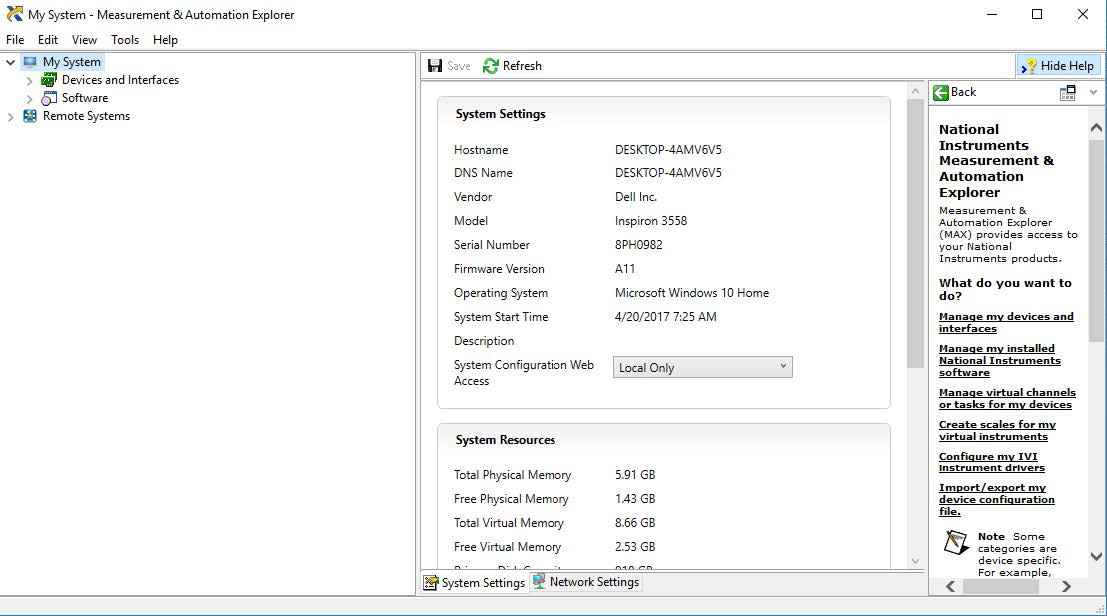

This will open the main window, as shown below:

3. Unlike USB, there is not an easy way to identify all of the instruments connected via LAN.

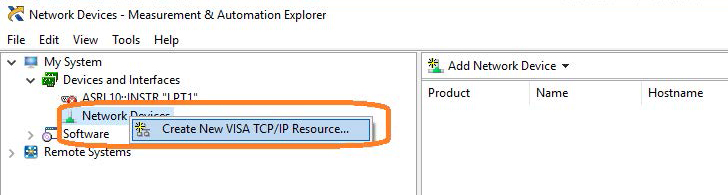

In many cases, you will have to manually add the LAN instrumentation. Recall from Step 2, our instrument IP address is 192.168.0.87

Right-click on Network Devices, and select Create New VISA TCP/IP Resource:

4. Select Manual Entry of LAN:

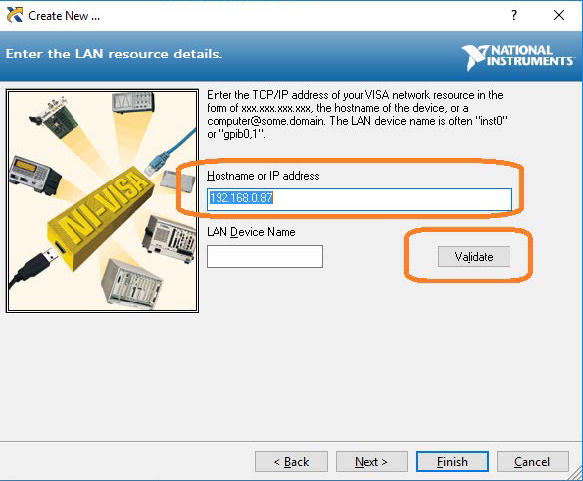

5. Enter the IP address and press Validate

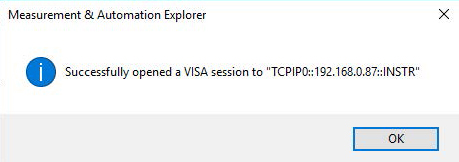

6. After successfully creating a TCP/IP connection, select finish

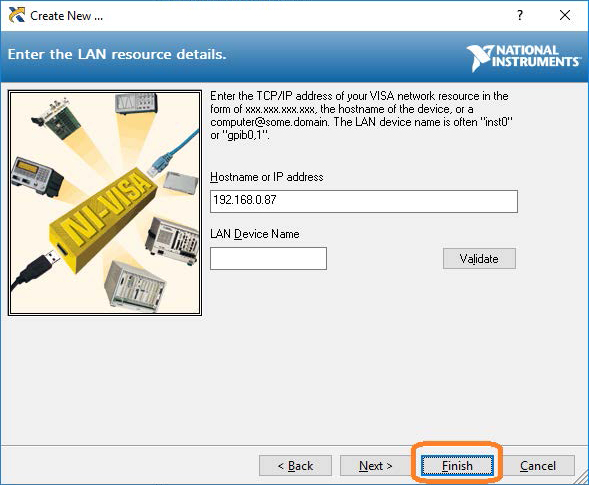

7. After the system updates it’s configuration, the instrument will appear in the Network Devices menu:

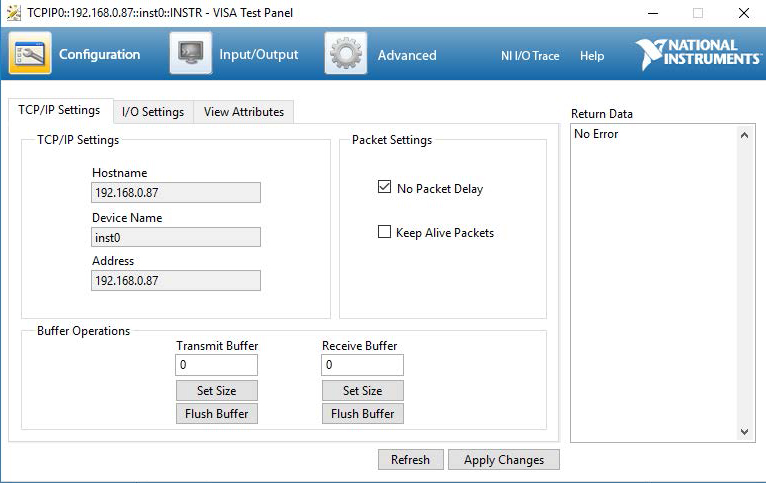

8. To further test the connection, right-click on the instrument and select Open VISA Test Panel or select it from the side bar:

The VISA Test Panel window shows some helpful information, including the TCP/IP identifier (VISA Address) along the top.

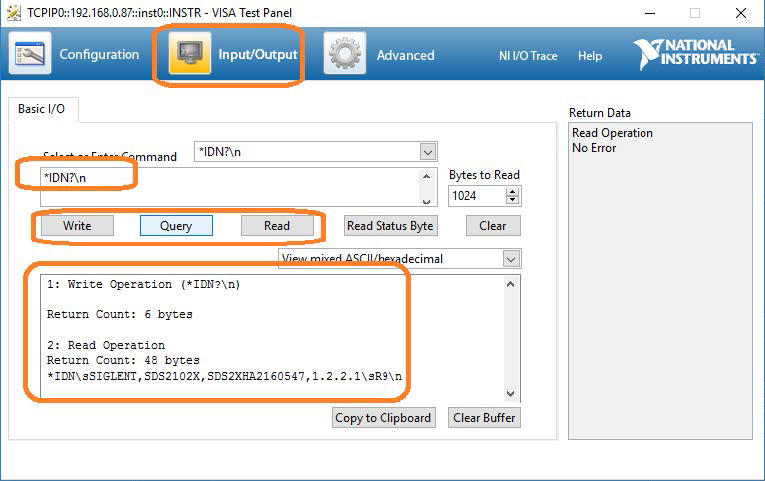

9. Another useful item in the VISA Test Panel is the Input/Output function. This mode allows you to send specific instrument commands and receive instrument responses.

This is especially helpful when you are planning a specific test sequence, the effect of delays/timing, or troubleshooting a command. You can send each command one-at-a-time and check the performance of the instrument.

Select Input/Output > Basic I/O > and Enter the command in the text window:

– *IDN? is a common identification string query (question or information request) that returns the information from the connected instrument

– /n is a termination character that represents a new line. This is the standard termination character for SIGLENT instrumentation.

– Write will send the command to the instrument

– Read will pull data from the instrument

– Query will perform a read and then a write command to request and return data from the instrument

For more information, check SiglentAmerica.com, or contact your local Siglent office.

SDS FFT performance on low frequency signals

Like many modern oscilloscopes, the SIGLENT SDS series feature FFT math functions that calculate frequency information from the acquired voltage vs. time data. FFT stands for Fast Fourier Transform, and is a common method for determining the frequency content of a time-varying signal. Converting time domain data to the frequency domain makes measuring characteristics like phase noise and harmonics much easier. Oscilloscopes don’t have the dynamic range or sensitivity of a true spectrum analyzer, but these new designs can provide a fine level of detail that may be just enough for your application.

FFTs are commonly used on high frequencies, but they can also be used on signals with fairly low frequencies.

In this note, I am going to show the FFT performance of two series of our scopes by sourcing a 10 mHz (100 s period), 10 Vpp sine wave using a SIGLENT SDG805 Function Generator into Channel 1.

For those interested, here are the specs for the SDG805

SDS1000X/SDS2000X Series:

The SDS1000X and 2000X series feature an FFT function that uses up to 16 kpts of timebase data to calculate the frequency data and a timebase maximum of 50 s/div.

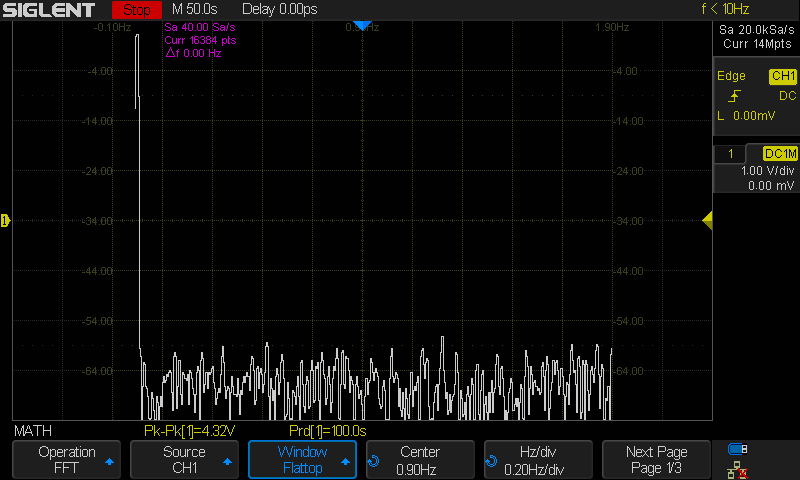

Here are the FFT results with the available window settings for a 10 mHz sinewave –

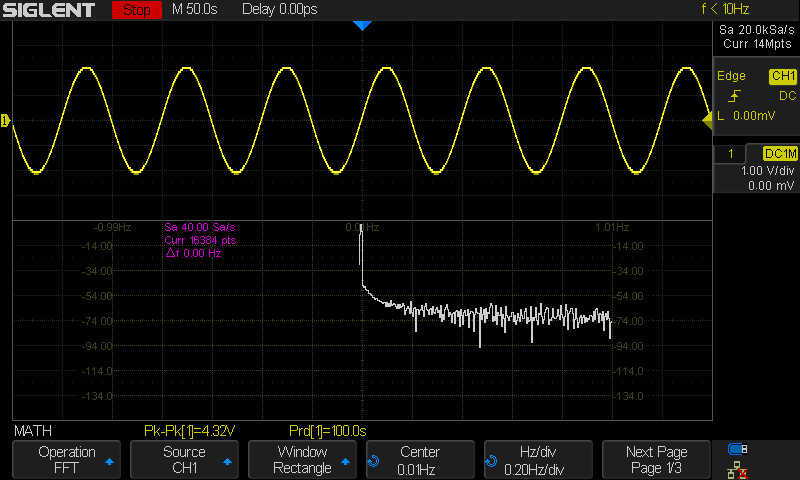

The scope can show a split timebase and FFT view:

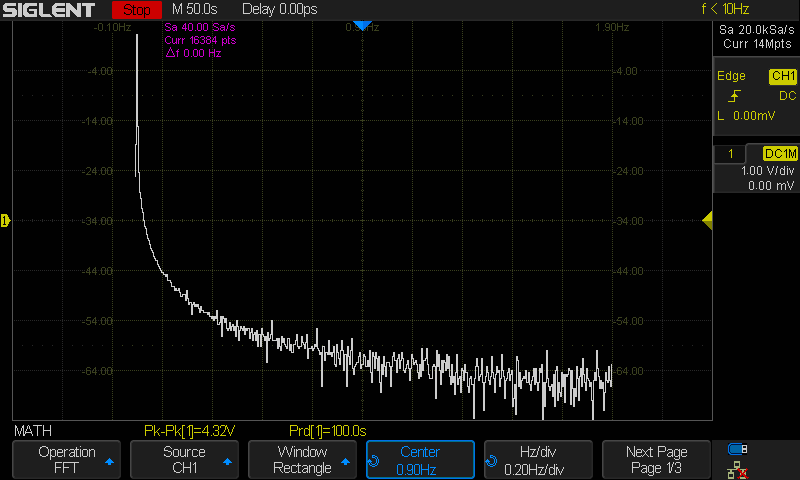

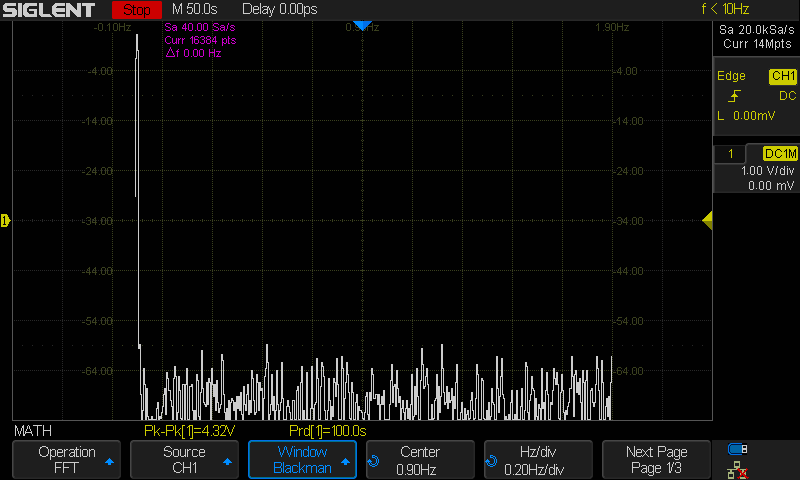

For the rest, I will use the exclusive FFT view.

Rectangle

Blackman

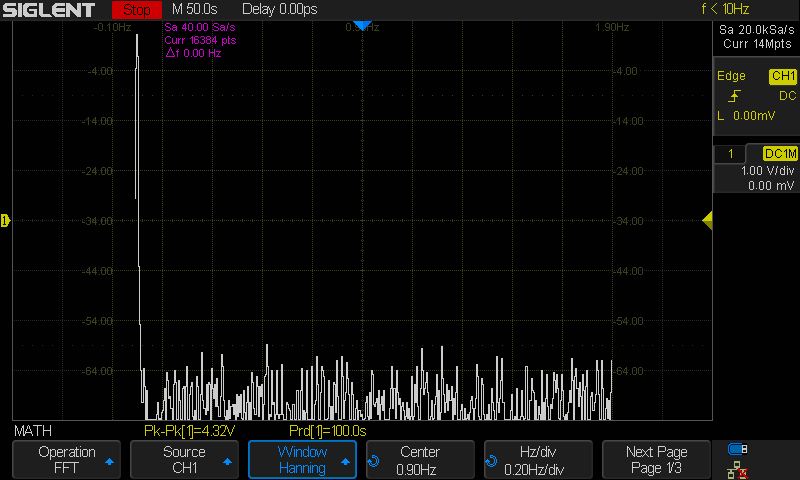

Hanning

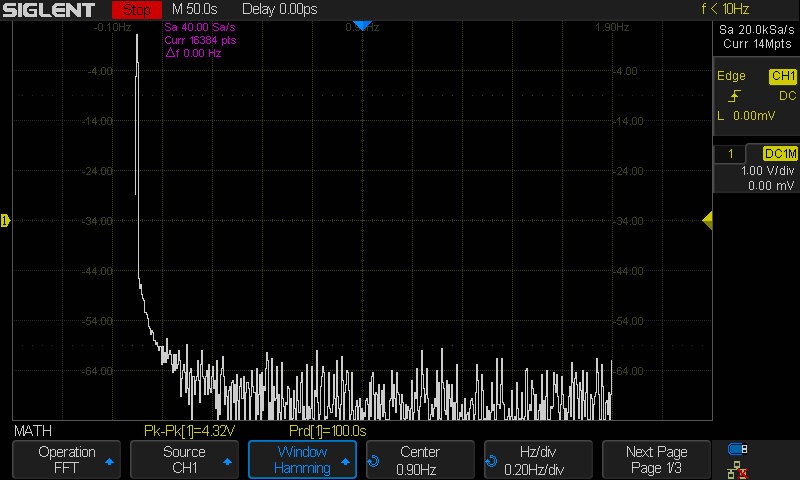

Hamming

Flat Top

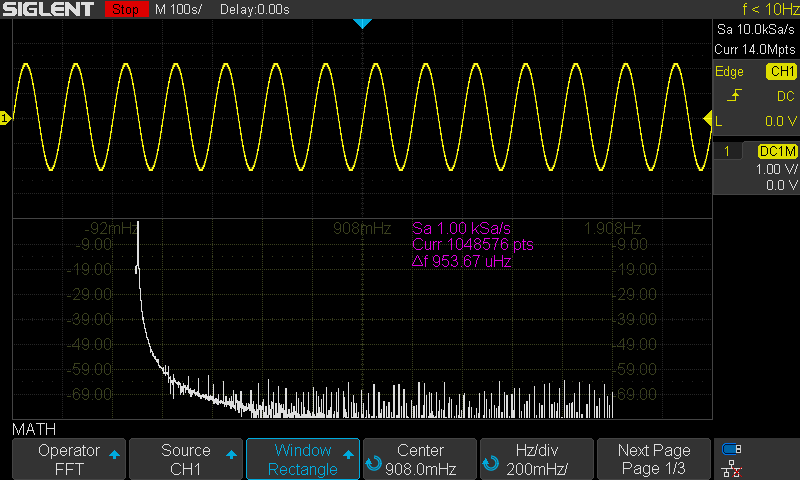

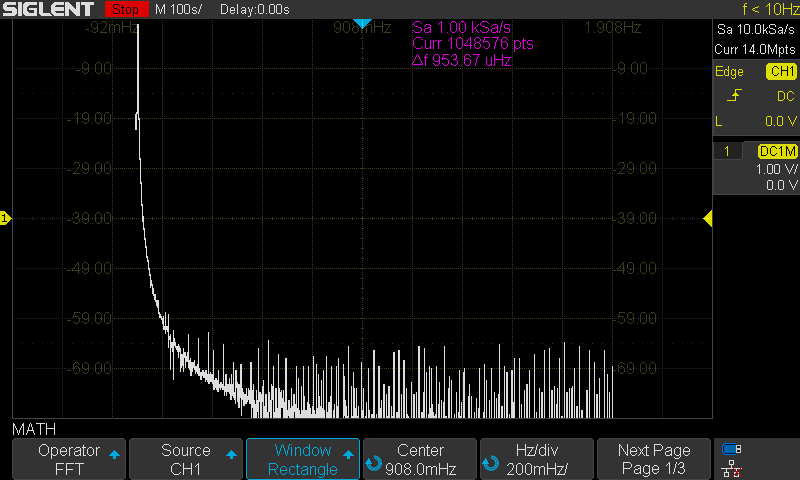

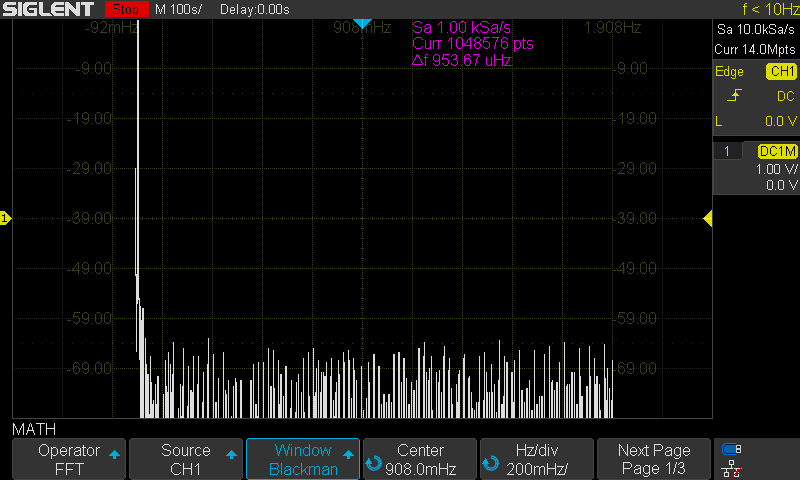

SDS1000X-E Series:

The SDS1000X-E series feature a new math co-processor that increases the maximum data depth of the FFT function to 1 Mpts. They also feature a timebase maximum of 100 s/div. These increases allow the X-E to have much finer timebase detail and to acquire useful data for even lower frequencies than many scopes on the market.

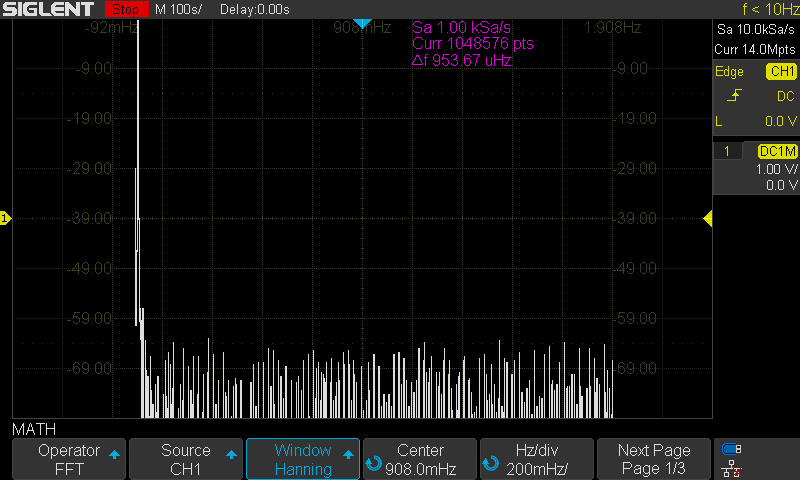

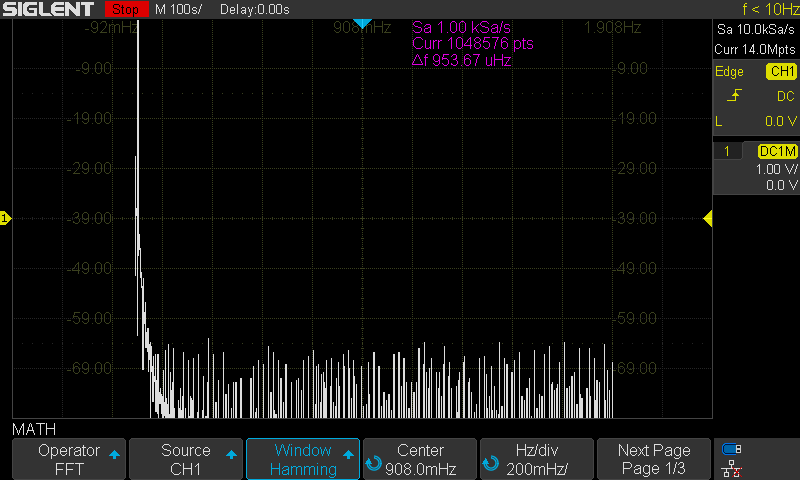

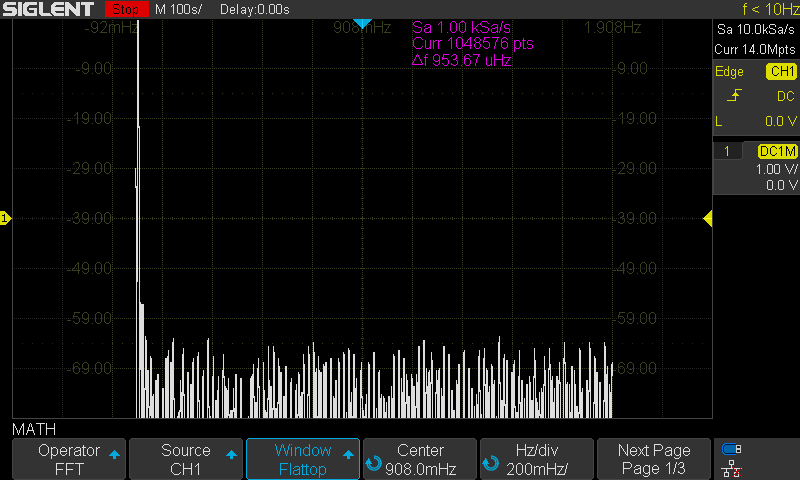

Here are the FFT results with the available window settings for a 10 mHz sinewave –

The scope can show a split timebase and FFT view:

For the rest, I will use the exclusive FFT view.

Rectangle

Blackman

Hanning

Hamming

Flat Top

Bode Plot of a filter using an oscilloscope and function generator

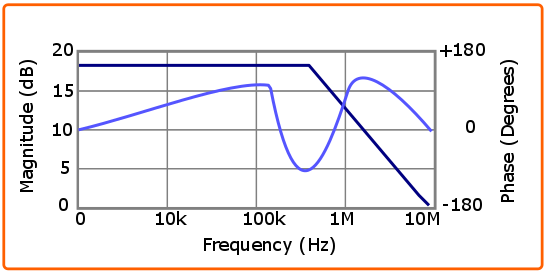

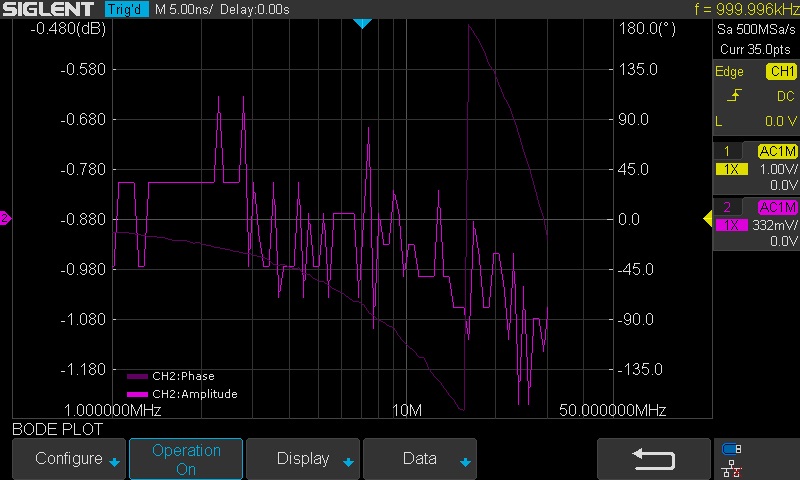

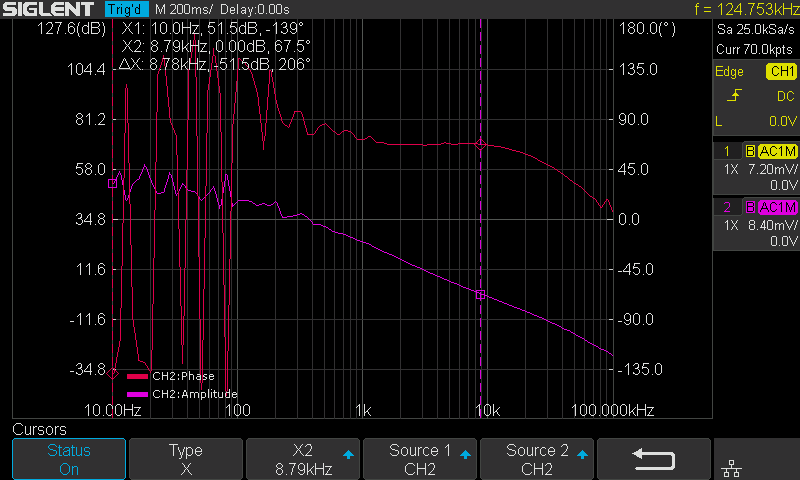

A Bode plot is a method of graphically displaying the frequency response of a system or device-under-test (DUT). Commonly, the magnitude and phase response of the device are plotted with respect to frequency using a shared horizontal frequency axis as shown in the example below:

By showing both the magnitude and phase information on the same graph, you can evaluate some of the basic qualities of the device being tested. A function generator and oscilloscope can be used to manually collect and compare the phase and amplitude data for a given device, but this can be tedious and time-consuming.

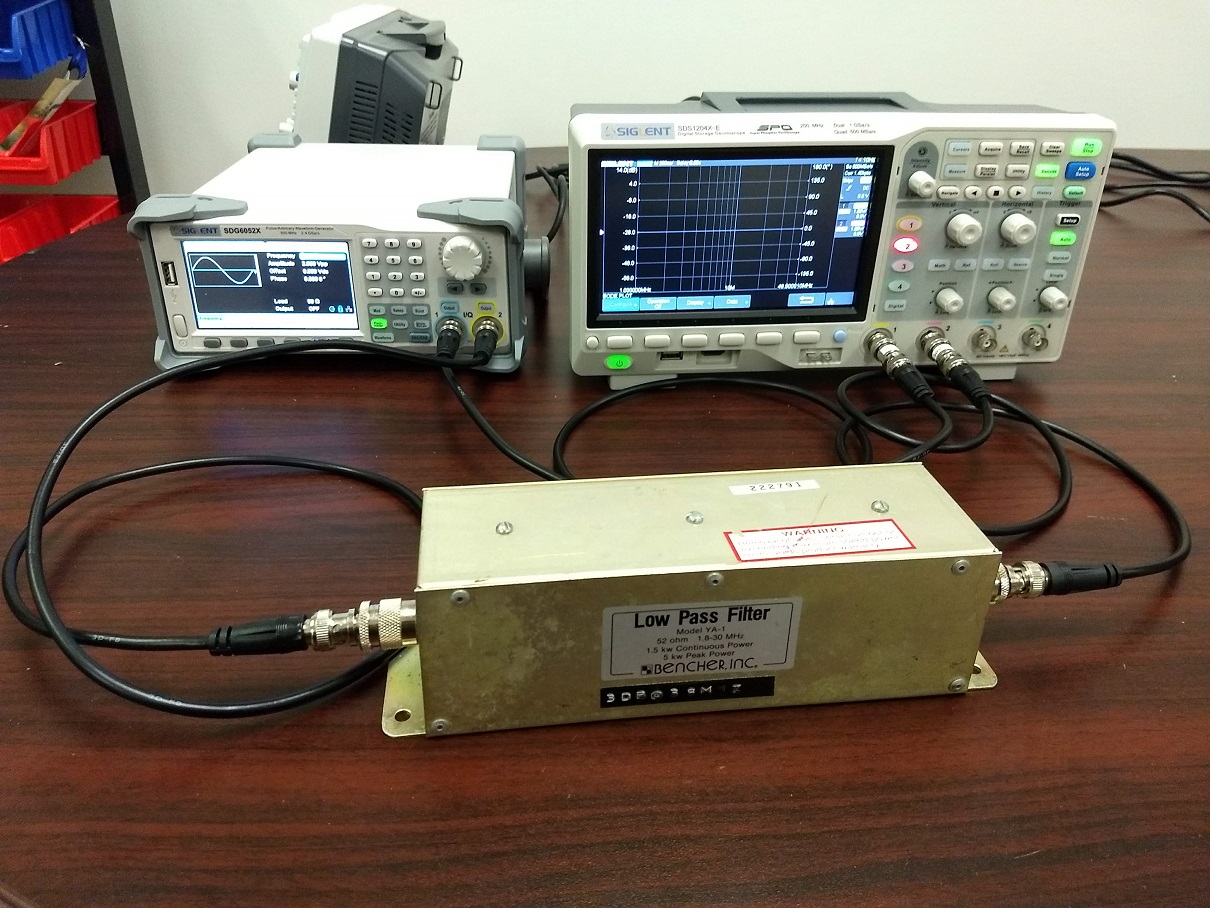

In this application note, we are going to characterize the frequency response of a low pass filter using the free automated Bode Plot function SIGLENT SDS10004X-E oscilloscope (SDS1204X-E, to be precise) and a SIGLENT SDG6000X Series (SDG6052X) arbitrary waveform generator. This automated control provides a clean and easy route to characterizing devices.

There is also a video covering this topic:

Let’s take a look at the required hardware.

Hardware:

- Qty 1 SIGLENT SDS1004X-E series four-channel oscilloscope. In this note, we will use a 200 MHz version (SDS1204X-E). The important thing to keep in mind is that the maximum bandwidth of the scope exceeds the maximum frequency we wish to measure. Remember that the maximum frequency shown on an on oscilloscope datasheet is usually the 3 dB point!

- Qty 1 SIGLENT SDG series function generator. In this note, we are using a 500MHz SDG6052X, but any SDG series (800/1000 series, 1X, 2X, 6X) can communicate via USB cable to an SDS1004X-E series of four- channel scopes. Just be sure that the maximum sine wave output frequency meets or exceeds your DUT requirements. Note, we could also use the X-E external function generator (part number SAG1021). It can provide up-to 25 MHz sine waves and can be used for Bode Plotting as well.

NOTE: The SAG1021 has only 1 output and requires a BNC “T” to create the direct and through connections to the scope.

- Qty 1 USB cable: For communication between the generator and scope

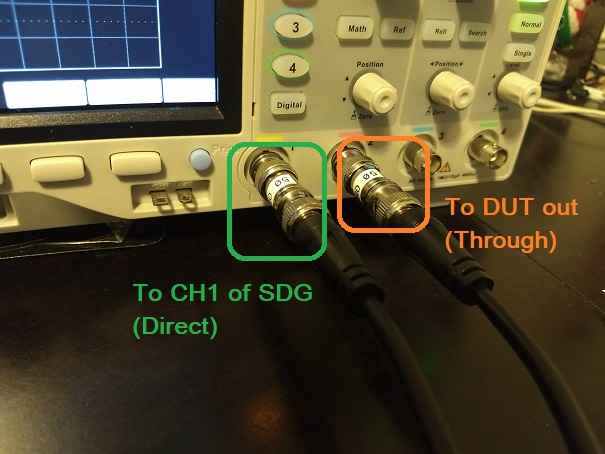

- Qty 2 50 Ohm BNC terminations: Matches the DUT impedance (50 Ohms) to the high impedance inputs of the scope (the X-E models do not have 50 Ohm inputs):

- Qty 3 BNC coaxial cables: Connect SDG out to DUT and the oscilloscope

- Qty 1 DUT (Device-under-test): We are going to test a 50 Ohm 30 MHz low pass filter:

Connections:

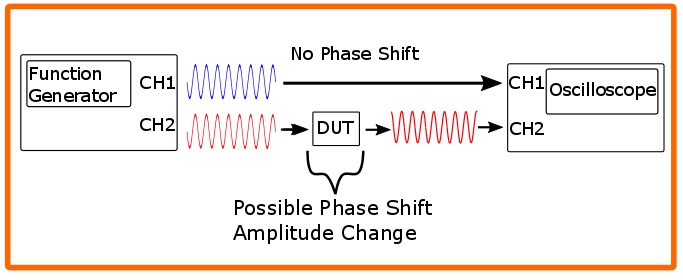

In this measurement, we want to see how the DUT effects the amplitude and phase of a known signal. One method to accomplish this involves sourcing two pure sine waves with identical amplitude and starting phase values. One of the signals is wired directly to an oscilloscope input (the “control” or “direct” signal). The second output (identical to the first) goes through the DUT and then to the scope. The DUT may affect the signal amplitude and phase. We can easily compare the two signals using the measurements performed with the scope and graph the amplitude and phase changes with respect to the input signal frequency.

Here is a simplified diagram of the test methodology:

Physical Connections:

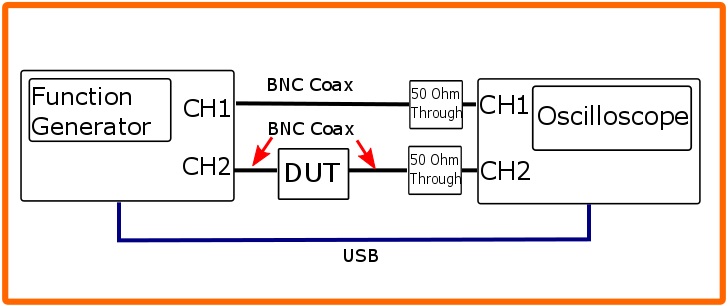

- Connect the SDG X series Generator CH1 Output > BNC cable > BNC 50 Ohm termination > SDS1204X-E Oscilloscope CH1 input

- Connect the SDG X series Generator CH2 Output > Appropriate cable > DUT input

- DUT output > appropriate cable > BNC 50 Ohm termination > SDS1204X-E Oscilloscope CH2 input

Here is a close up of the 50 Ohm terminators on the scope:

- SDG X series Generator > USB Cable > SDS1204X-E Oscilloscope USB control (either front or rear USB location will work. Rear as shown below)

Here is a picture after the connections are complete (NOTE the USB cable between instruments is hidden):

Configure and Run:

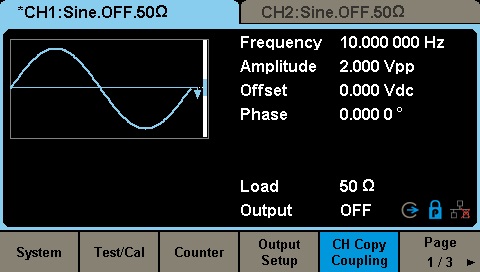

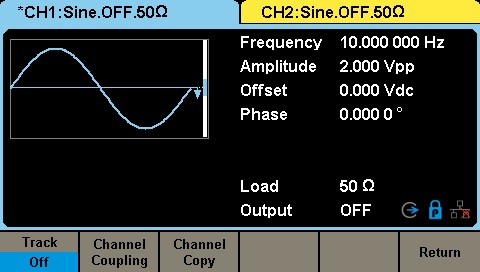

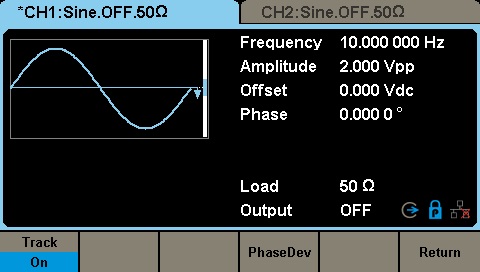

First, let’s configure the generator so that CH1 and CH2 are identical signals and they start at the same time. The SIGLENT SDG X series of generators feature a handy tracking feature that forces the settings and actions on CH1 to be mirrored on CH2.

To enable Tracking:

- Press Utility > CH Copy Coupling (Page 1/3)

2. Set Tracking > ON

Now, we can go back to the oscilloscope and configure the sweep parameters and run the test.

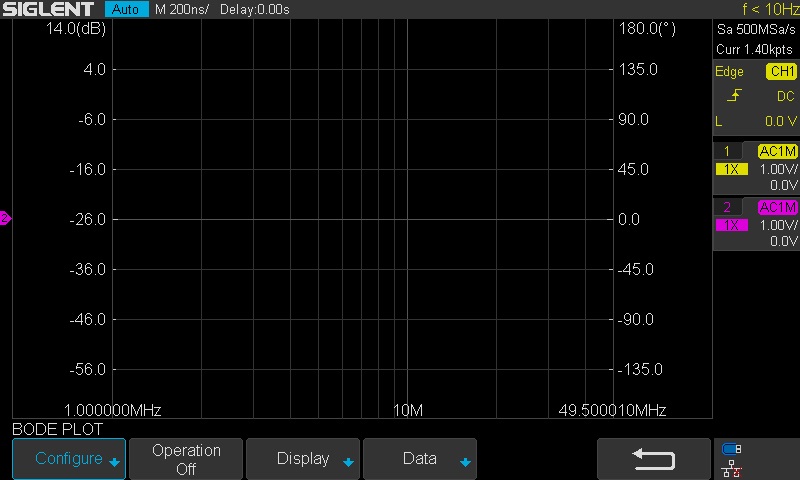

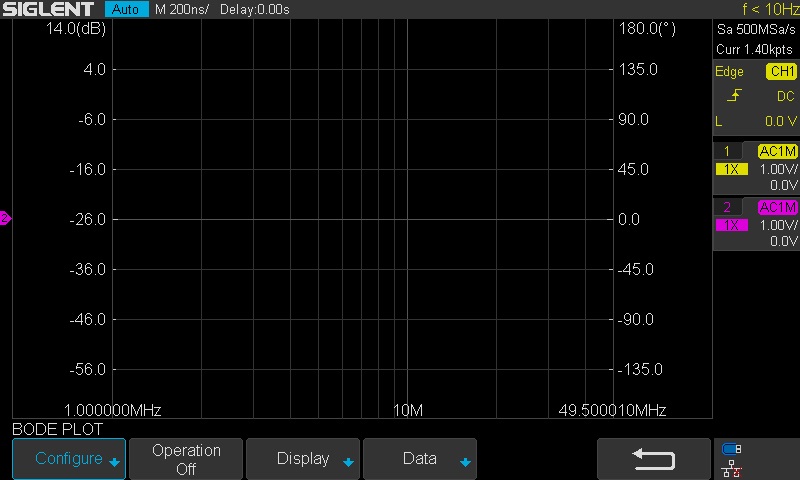

- On the front panel of the scope, press Utility > and arrow down until you get to page 2 > Select Bode Plot

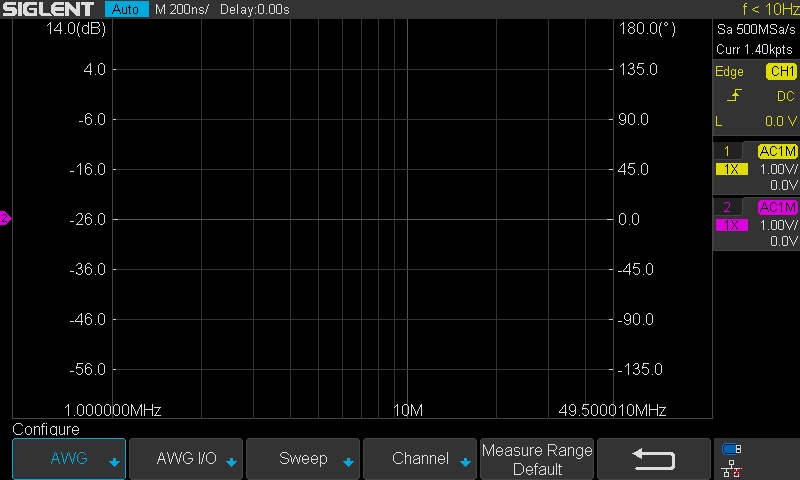

This opens up the Bode Plot menu:

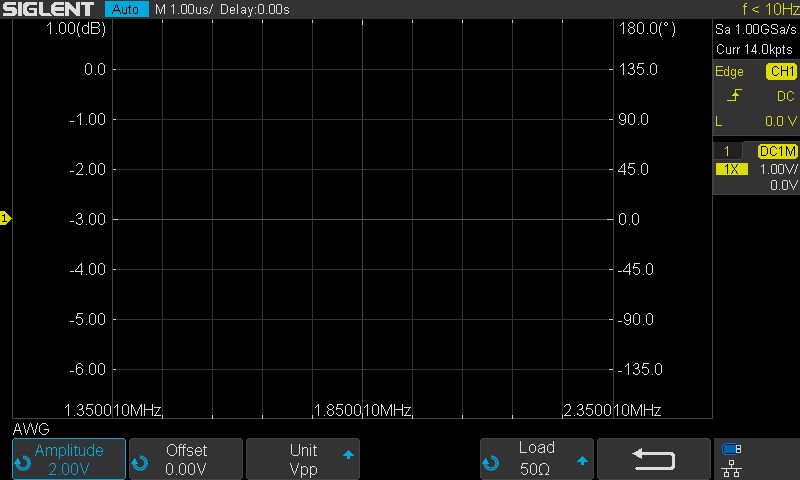

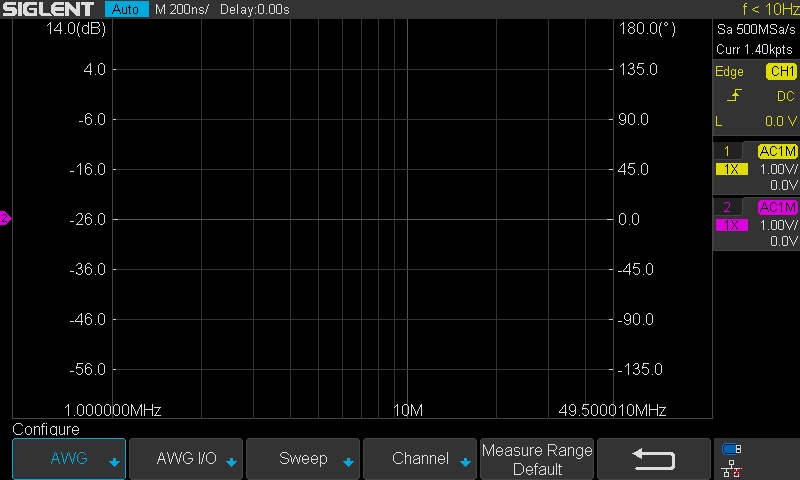

2. Press Configure to open up the generator Configure (AWG) controls and sweep parameters:

3. Press AWG to set the signal amplitude and set expected device load impedance. Press the back arrow to return to the Configure screen.

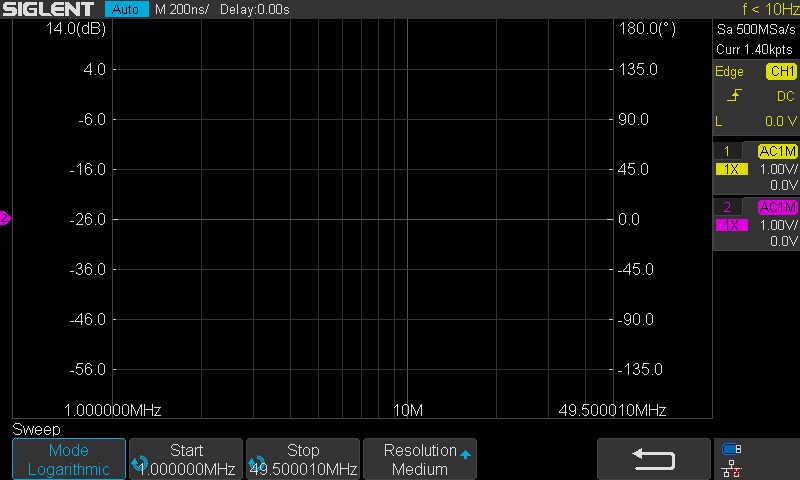

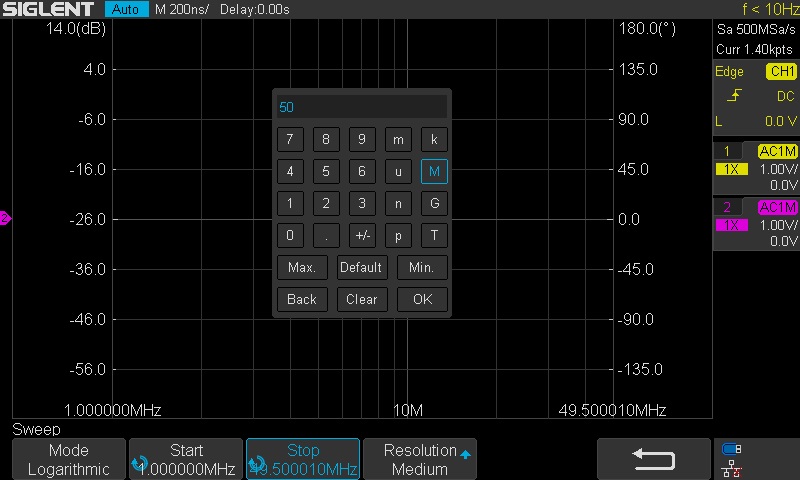

4. Press Sweep to open the Sweep menu. Here, you can set the mode, sweep start/stop frequencies and resolution:

To set the Start and Stop frequencies, press the appropriate soft key (Start or Stop).

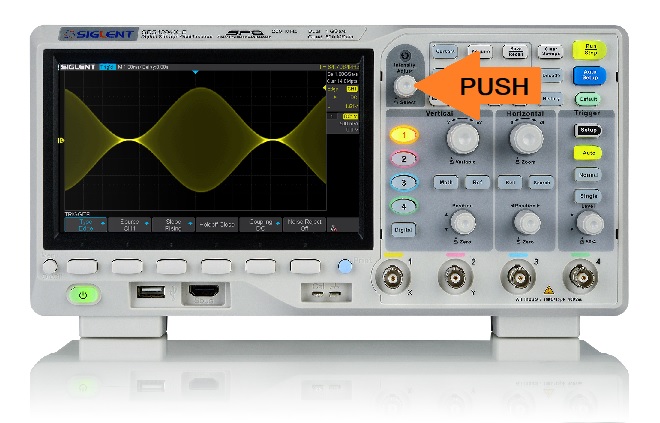

You can change the input value by rotating the intensity knob.

Alternately, you can press the intensity knob to display the units keyboard.

Now, rotate the knob to highlight a character or unit and press the knob to enter:

6. Press the back arrow to return to the Configure screen.

7. Now, confirm the channel connections by pressing Channel:

Here, you can see we have DUT input (the direct signal from the generator) connected to Oscilloscope channel 1. The scope CH2 is connected to the DUT output (the through connection).

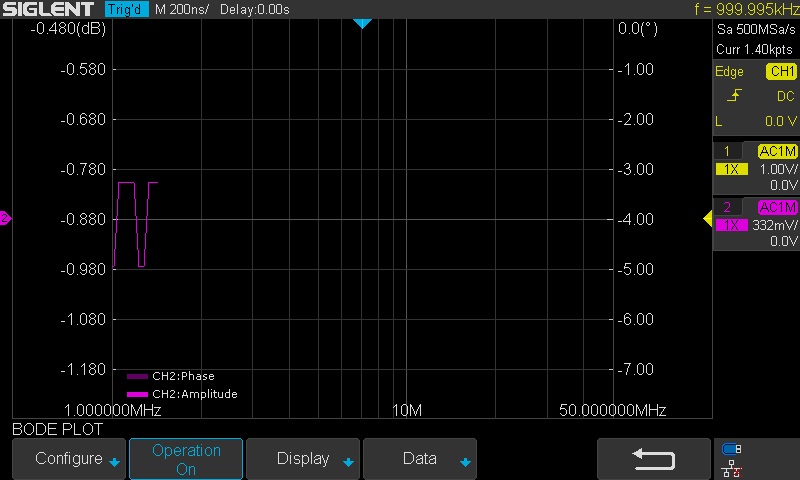

8. Back arrow twice to get to the Bode Plot screen. Now, you can set Operation = ON to run the test:

- The generator outputs should be enabled and the frequency values will start to change as the generator sweeps the output

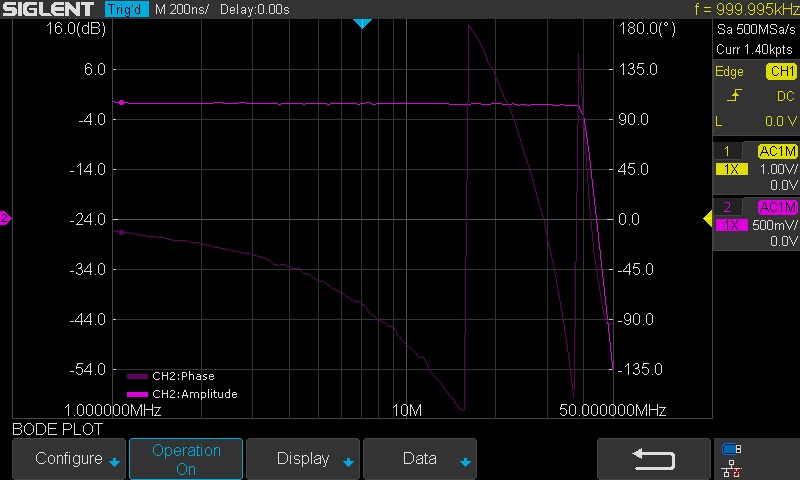

- The oscilloscope will begin to plot the amplitude and phase vs. frequency as shown (Since we selected scope input CH2, the Phase is dark pink. Amplitude is light pink. Data from CH1 has shades of yellow. CH3 data has shades of blue. CH4 data has shades of green):

As the data is collected, there may be some range changing..

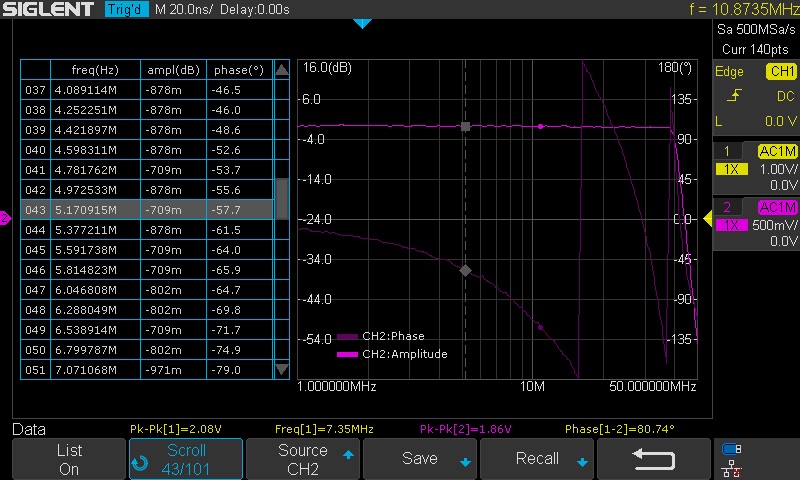

Finally, the sweep is complete.. we can see data from the start to the stop frequency:

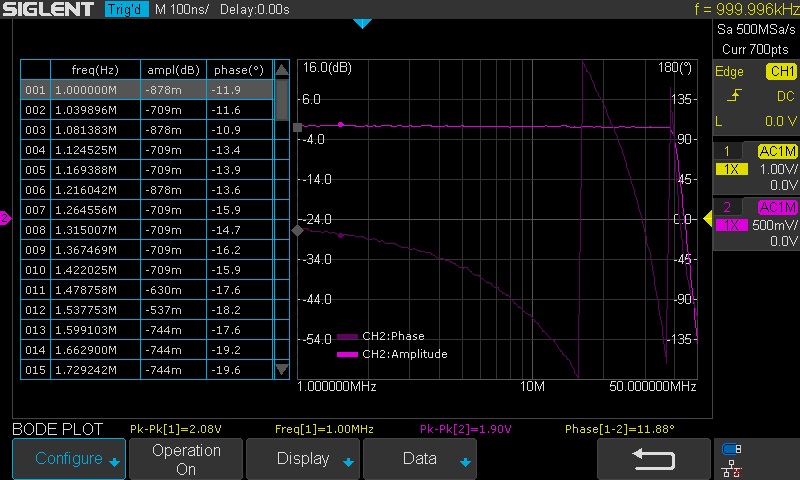

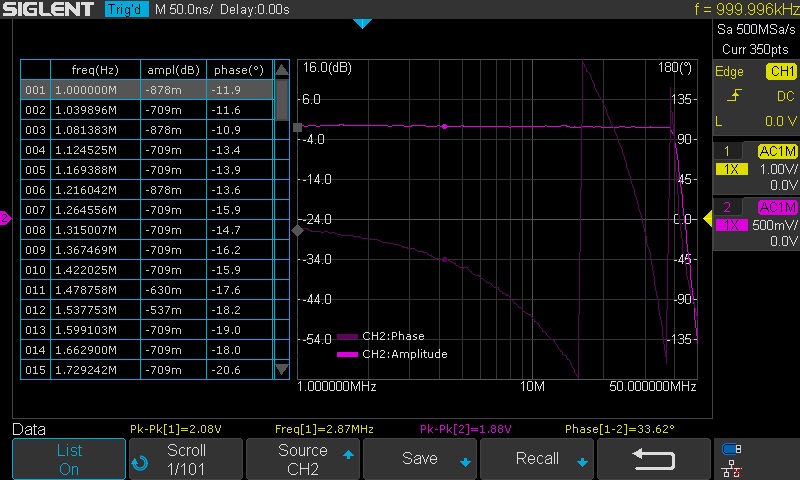

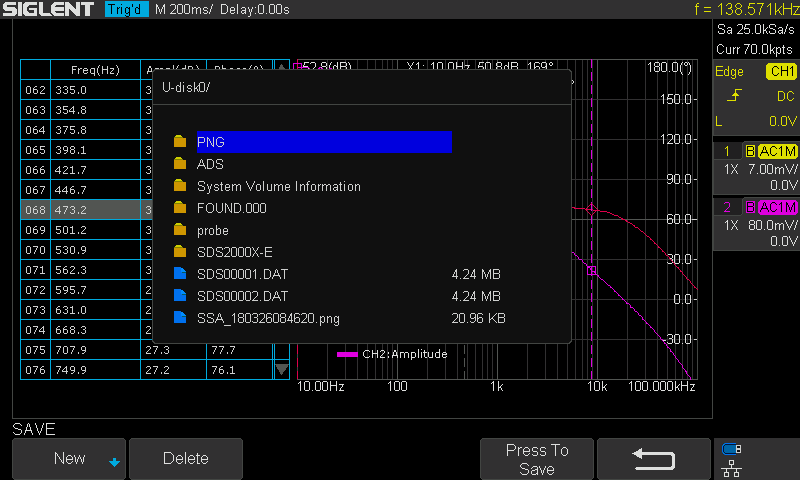

Now, you can print a picture of the display or you can open up the list table to see each data point by pressing Data:

From the Data menu, you can enable the list view:

And scroll through each data point:

From here, you can use the scroll and cursors to find individual data points, quick print display images to USB, and save CSV data to USB using the Save function.

The Time Domain:

At the beginning of this note, we explained briefly that you can manually collect the amplitude and phase information.

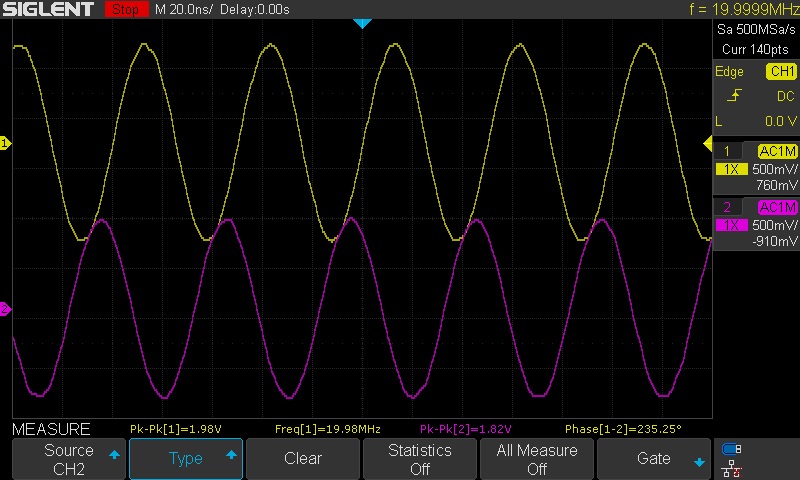

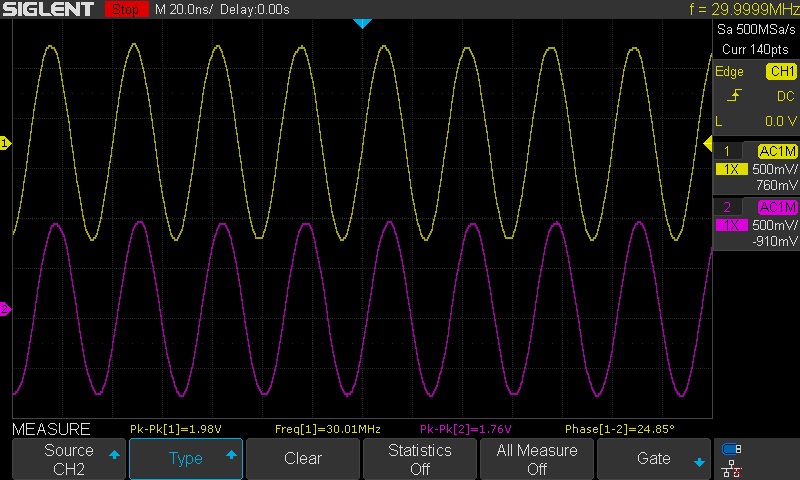

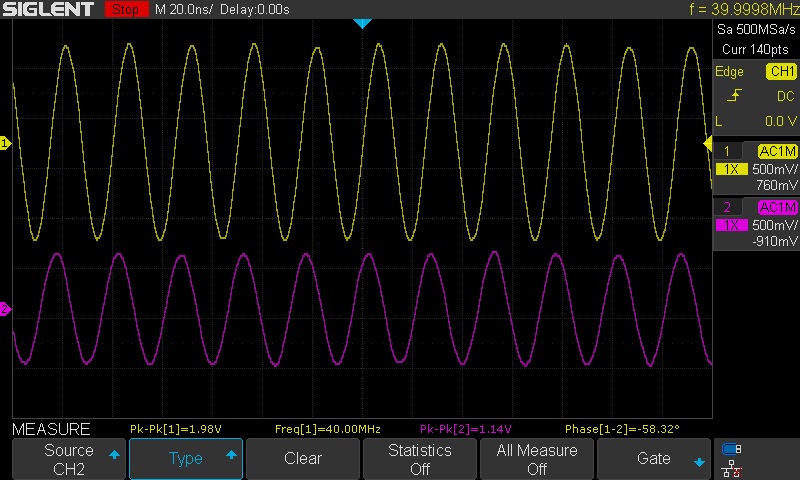

Here are a few oscilloscope frames captured manually sweeping and measuring the direct (CH1/Yellow) and through signals (CH2/Pink):

1MHz:

20 MHz (Note amplitude and phase changes):

30 MHz:

40 MHz:

Finally, we see 50 MHz.. and the through signal (through the filter) is severely attenuated.

Programming Example: Retrieve data from an XE series Oscilloscope using Kotlin

The SDS series of oscilloscopes all feature remote programming and data collection capabilities. They can be integrated easily into many automated test environments to ease the setup and data acquisition during testing.

One of our helpful customers developed a nice programming example designed to set up and retrieve data from a SIGLENT SDS1202X-E Oscilloscope using Kotlin, a free open source coding environment (more on Kotlin here).

The code utilizes a LAN connection and open sockets.

Thanks to Chris Welty for the code!

Here is a text file of the example:

/**

* License: 3-Clause BSD

*

* Copyright 2018 Chris Welty

*

* Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are met:

*

* 1. Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer.

*

* 2. Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the documentation and/or other materials provided with the distribution.

*

* 3. Neither the name of the copyright holder nor the names of its contributors may be used to endorse or promote products derived from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING,

* BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO

* EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR

* CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR

* PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY,

* OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

* POSSIBILITY OF SUCH DAMAGE.

*/package scope

import java.io.BufferedWriter

import java.io.OutputStreamWriter

import java.io.Serializable

import java.net.Socket/**

* Contains a single waveform downloaded from a Siglent 1202X-E

*/

class Waveform(val vDiv: Double, val vOffset: Double, val tDiv: Double, val tOffset: Double, val data: ByteArray) : Serializable {val xs: DoubleArray

get() = DoubleArray(data.size, { i -> i * tDiv * 14 / data.size + tOffset – tDiv * 7 })val ys: DoubleArray

get() = DoubleArray(data.size, { i -> data[i] * vDiv / 25 – vOffset })companion object {

/**

* Download the waveform displayed on the scope’s screen

*/

fun download(): Waveform {

Socket(“192.168.1.222”, 5025).use { socket ->println(“connected to ” + socket.inetAddress)

val output = BufferedWriter(OutputStreamWriter(socket.getOutputStream(), Charsets.US_ASCII))// since the socket can return binary data, we can’t use an InputStreamReader to

// translate the bytes to characters. We’ll have to do it ourselves.

// SCPI generally uses US ASCII, shouldn’t be too hard.

val input = socket.getInputStream()/**

* Read from the scope until \n is encountered.

* The bytes are translated to characters numerically (so US_ASCII).

*/

fun readLine(): String {

val sb = StringBuilder()

while (true) {

val c = input.read()

when (c) {

-1, ‘\n’.toInt() -> return sb.toString()

else -> sb.append(c.toChar())

}

}

}/**

* Read a number of bytes from the scope.

*

* The bytes are not translated into characters.

*/

fun readBytes(n: Int): ByteArray {

val result = ByteArray(n)

var i = 0

while (i < n) {

i += input.read(result, i, n – i)

}

return result

}fun writeLine(string: String) {

output.write(string)

output.write(“\n”)

output.flush()

}/**

* Read a numerical response from the scope.

*

* The scope returns responses like “C1:VDIV 1.00E+00V”.

* This function extracts the “1.00E+00″, converts it to a double, and returns it.

*/

fun readNumber() = readLine().split(” “)[1].dropLast(1).toDouble()writeLine(“*IDN?”)

println(readLine())// reset the scope response format to its default so readNumber() works

writeLine(“CHDR SHORT”)writeLine(“C1:VDIV?”)

val vDiv = readNumber()writeLine(“C1:OFST?”)

val vOffset = readNumber()writeLine(“TDIV?”)

val tDiv = readNumber()writeLine(“TRDL?”)

val tOffset = readNumber()// request all points for the waveform

writeLine(“WFSU SP,0,NP,0,F,0”)

writeLine(“C1:WF? DAT2”)// parse waveform response

val header = String(readBytes(21))

println(“header is $header”)

val length = header.substring(13, 21).toInt()

println(“length is $length”)

val data = readBytes(length)

readBytes(2) // 2 garbage bytes at endprintln(“V/div = $vDiv; offset = $vOffset; t/div = $tDiv; tOffset = $tOffset”)

return Waveform(vDiv, vOffset, tDiv, tOffset, data)

}

}

}

}

Testing Open Socket Communications Using PuTTY

Many instruments include the ability to be controlled via a remote connection to a computer using an Ethernet connection. In many cases, these instruments require a special software library that can help establish and maintain the communications link between the instrument and controlling computer. This can be annoying for a few reasons… the software library is likely to occupy a large amount of space on the controlling computer and is also required on any computer that is being used to control the instrument. In a remote networking application where multiple user’s may want access to a test instrument, this can cause support and installation headaches.

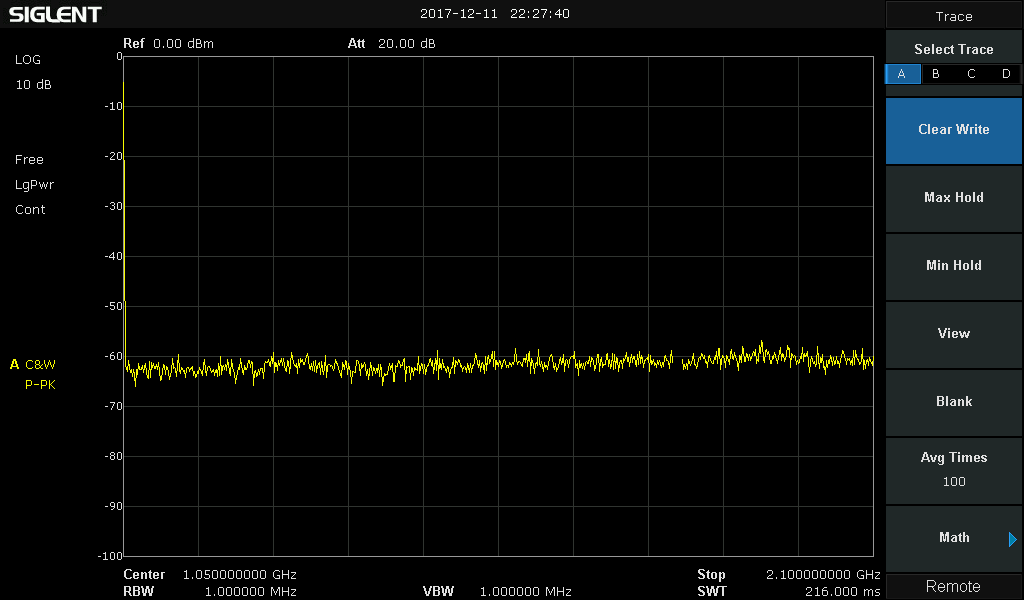

Luckily, there are a few solutions that can help. In this application note, we are going to discuss using open socket communication techniques using an open source communication tool called PuTTY with a SIGLENT SSA3032X spectrum analyzer.

What are open sockets and why use them?

Within the context of Ethernet/LAN connections, sockets are like mailboxes. If you want to deliver information to a specific place, you need to be sure that your information is delivered to the correct address.

In the context of test instrumentation, an open socket is a fixed address (or port number) on the Ethernet/LAN bus that is dedicated to process remote commands.

Open sockets allow remote computers to simply use existing raw Ethernet connections for communications without having to add additional libraries (VISA or similar) that require additional storage space and processing overhead.

Programs that utilize sockets for LAN communication tend to take up less memory and operate more quickly.

PuTTY

PuTTY is an open source software tool that provides a number of simple communication links (RAW, Telnet, SSSH, Serial, and others). It is available for free and there are a number of versions available for popular operating systems.

You can download as well as learn more here: https://www.putty.org/

In this example, we are using PuTTY to verify the raw LAN connection is working properly. It is quite a simple program that does not allow for very complex operation (sequences, converting data sets/strings, etc..). If you require more complex functionality, software platforms like Python, .NET, C#, LabVIEW, etc.. can be used to control the instrument using a similar open socket connection.

Configuration

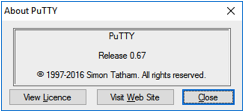

In this test, we are using the most current revision of the SIGLENT SSA3032X Spectrum Analyzer firmware (Revision 01.02.08.02) which enables open socket communication.

This example also uses PuTTY version 0.67:

Steps

1. Install PuTTY for the OS you intend to use

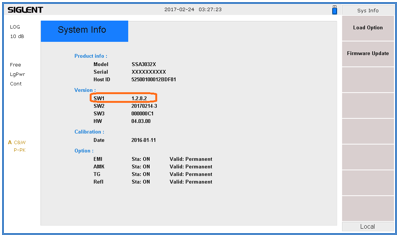

2. Make sure your instrument and firmware revision can use open sockets

The SSA3032X revision 01.02.08.02 enables open socket communication.

To find the revision, press the System button > Sys Info.

Figure 1 below shows a sample system information screen from a SIGLENT SSA3000X analyzer:

Figure 1: Sample system information page from an SSA3000X.Check the product page and firmware release notes for more information.

3. Connect the instrument to the local area using an Ethernet cable

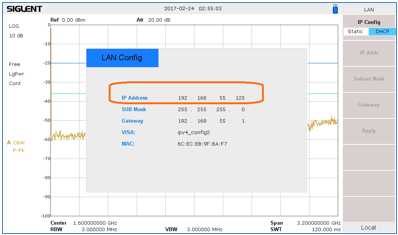

4. Find the IP address for the instrument. This is typically located in the System Information menu. On the SIGLENT SSA3032X, press the System button on the front panel > Interface > LAN.

Figure 2 below shows a sample LAN setup page from a SIGLENT SSA3000X:

Figure 2: Sample LAN information page from an SSA3000X.5. Open PuTTY

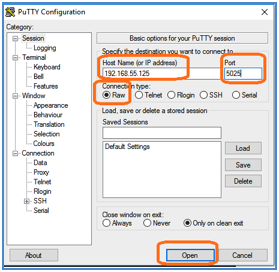

6. Select Raw as connection type

7. Enter the IP address in the Host Name field

8. Enter the port number. This should be provided in the users or programming guide for the instrument.

The SIGLENT SSA3000X uses port 5025.

Figure 3 below shows the PuTTY configuration for this example:

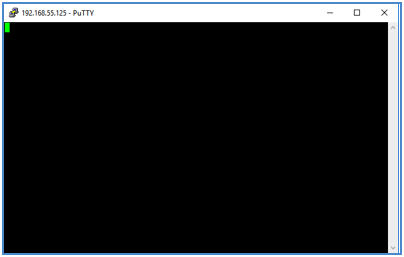

Figure 3: Example PuTTY configuration.9. Press Open. This will open a terminal window as shown in below:

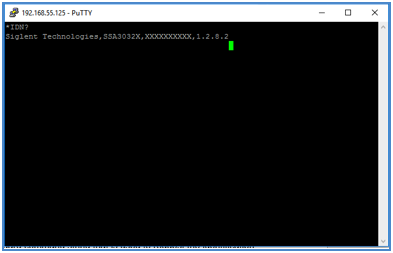

10. Using the computer keypad, enter *IDN? and press the Enter key on the keyboard to send the command.

This is the standard command string that is used to request the identification string from the instrument. As shown below, the instrument responds with the manufacture, product ID, Serial Number, and firmware revision.

Conclusion

PuTTY is an easy way to verify an operational LAN connection to instrumentation that can use open sockets.

Measuring the Modulation Index of an AM Signal using an FFT

In AM schemes, the modulation index refers to the amplitude ratio of the modulating signal to the carrier signal. With the help of Fast-Fourier-Transforms (FFT), the modulation index can be obtained by measuring the sideband amplitude and the carrier amplitude. In this application note, we are going to show a convenient method of using the new Peaks/Markers function (Available on the 4 channel SIGLENT X-E scopes with firmware revisions > 6.1.31).

1. Basic Principle

Amplitude modulation uses a signal (typically a sine wave in the audio frequency range from 10 Hz to 20 kHz) to control the amplitude of a higher frequency signal called the carrier.

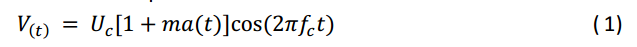

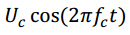

A carrier with amplitude modulation can be represented as

Where:

V(t) The Amplitude Modulated Signal

Uc Amplitude of the Carrier Signal

m Modulation Index

a(t) Normalized Modulation Signal

fc Carrier Frequency

Sinusoidal (commonly referred to as a “sine” wave) modulation is the most commonly used modulation waveform type. If we are using a sine wave, the modulating signal can be expressed as

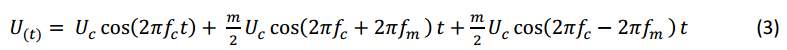

According to the formulas (1) and (2), we can get

Mathematically represents the carrier waveform.

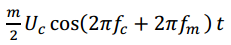

Mathematically represents the carrier waveform. and

and  represent the positive, or upper, and negative, or lower, sidebands of the modulated signal.

represent the positive, or upper, and negative, or lower, sidebands of the modulated signal.The amplitude of both sidebands are

If we set the amplitude of sideband is Us,

In logarithmic case, if the difference between the sideband amplitude and the carrier amplitude is X,

Then the amplitude modulation index can be represented as

Figure 1

Here, we can see that it is easy to measure the difference between the sideband amplitude and the carrier amplitude, or X. We can then calculate the modulation index very easily.

2. Measurement Setup and Result

2.1 Equipment

Oscilloscope: Siglent SDS1204X-E with firmware version higher than 6.1.31.

Signal Source: Siglent SDG2122X

Cable: 50 ohm BNC

2.2 Instrument Configuration

In this section, we will show how to configure the instruments in order to make the measurement. For complete instructions on the FFT mode, please refer to the oscilloscope user manual and the quick start guide.

The oscilloscope is connected to the output of the signal source as shown in Figure 2.

Figure 2 Set Up for the Measurement

The signal source settings are as follows:

- Mod On

- Mod Type: AM modulation

- Carrier frequency: 1 MHz

- Carrier amplitude: 500 mVpp

- Modulation frequency: 10 kHz, and the modulation index is 80%.

According to the output of the signal source, set the center frequency of the FFT plot to 1 MHz and set the horizontal scale to 5 kHz to provide a clear view of the output.

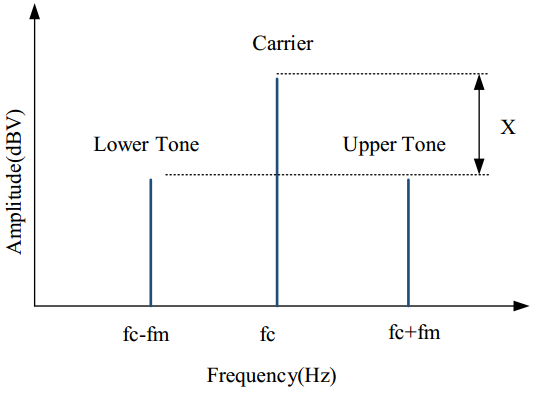

To reduce random errors, the FFT is set to average mode and the average number of times is 100. On the choice of window function, we choose flat-roofed window to obtain the optimized amplitude accuracy.

Starting with firmware revision 6.1.31, the FFT function of Siglent X-E oscilloscopes include a Peaks/Markers function and users can set the number of FFT points separately. The more points the FFT has, the better the frequency resolution of the plot will have. Note that increasing the number of points will increase the time of computation of the FFT, which will reduce the refresh speed accordingly. FFTs up to 1 Mpts at most are available on the X-E series, so we can set the storage depth to 1.4 Mpts. In this application, there is no need for a high sampling rate, since that will lead to a large delta frequency. Set the timebase to 2ms.

According to the input signal, we can deduce that a frame waveform has 28 k-cycles and we will use the first 20 k-cycles to do the FFT operations. For decent resolution, there should be at least five sample points in a cycle, so the minimum number of FFT points should be at least 100 kpts. 128 kpts is suitable, since under the premise of satisfying the measurement conditions, we can get the results faster.

The new version also supports Peaks/Marker, it can quickly identify and label peaks. We choose Peaks to make the measurement.

Figure 3 Configuration Screens

The configuration process is as follows:

First, set timebase to 2ms and enter the ACQUIRE menu, set Mem Depth to 1.4M. Second enter the MATH menu, set Operator to FFT, enter the CONFIG menu, setMaximum points to 128k, set Window to Flattop, set Display to Exclusive then go to the next page, set Mode to Average, set Times to 100. Third enter the VERTICALmenu, set Unit to dBVrms, then enter HORIZONTAL menu, set Center to 1MHz, set Hz/div to 5 kHz. Last, enter the FFT TOOLS menu and set Type to Peaks, turn on theShow Table switch to show the peaks list and turn on the Show Frequency switch to show the frequency of peaks, set Sort By to Frequency.

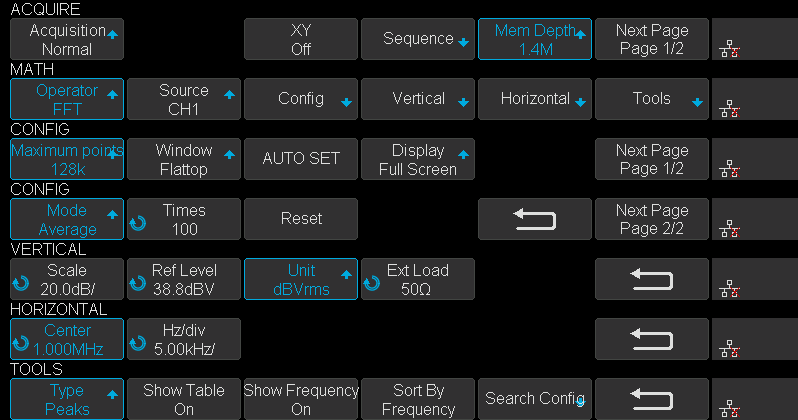

2.3 Result

After configuration is done, enter SEARCH menu, adjust Threshold to show several peaks for easy reading from the table then press Reset. After the average number increasing to 100, the FFT result as shown in Figure 4.

Figure 4 FFT Peaks Result

The carrier amplitude is -14.9dBV, the sideband amplitude is -22.8dBV. So the difference between the sideband amplitude and the carrier amplitude is -7.9dB.

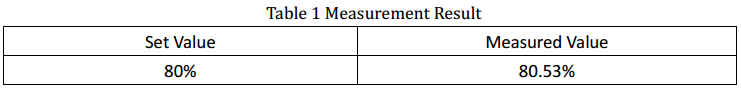

According to the previous introduction, the results of the modulation index are shown in the table 1.

Table 1 Measurement Result

3. Summary

The Siglent oscilloscope with newly released Peaks/Markers software, supports peak and harmonic searching which provides a convenient method of spectrum analysis.

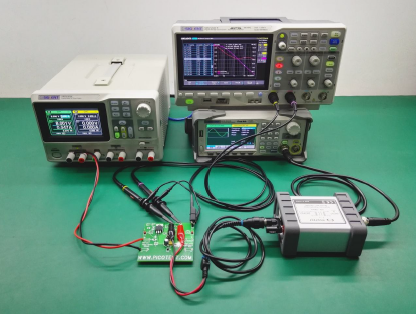

Power Supply Design: Load Step Response with a SIGLENT DC Electronic Load

Building a power supply that can handle various loads without oscillating can be a challenge. Computational models and computer simulations can help get your design headed in the right direction, but physical testing is essential to proving the performance of your design.

One method of quickly determining stability is to use a load step response.

In this test, a DC electronic load is used to provide a current load that steps from a low current draw to a higher value in a short period of time. By directly measuring the voltage and current output of the supply with the stepped load, we can visually observe the recovery of the power supply feedback loop and make changes to the design to optimize the response.

For this note, we are going to perform identical tests on two supplies and compare the output voltage and current waveforms: One has been tuned so that the output quickly recovers with minimal overshoot and ringing. The other supply is not tuned and subsequently oscillates. We will also discuss some measurement techniques to help get the right data as quickly as possible.

We also have a video to accompany this note:

Power Supply Design: Load Step Response with a SIGLENT DC Electronic Load

The Equipment:

- A DC Electronic Load: The SIGLENT SDL1020X-E is a 200 W load with dynamic testing capabilities to perform the load step. It also features remote sense capabilities to compensate for the voltage drop across the load leads. High currents can provide a substantial voltage drop across the leads and will add unwanted error.

- An oscilloscope: The SIGLENT SDS2354X Plus scope has a large display, easy-to-use interface, and features that make capturing these waveforms very easy.

- A power supply: The SIGLENT SPD1168X single output supply delivers power to our power supply board

- A current probe: The SIGLENT CP4070 features a 150 kHz bandwidth that will minimize most switching noise from the measurement

- Power supplies to test: The Analog Devices LTM4646 series of uModule Regulators. This module features two 10A DC-DC converters. One has been “detuned” to show some common problems associated with power supply design. The other supply has been left in it’s tuned state as a comparison to the detuned supply.

Programming Example: Open Socket LAN connection using Python

Automating a test can dramatically increase the productivity, throughput, and accuracy of a process. Automating a setup involves connecting a computer to the test instrumentation using a standard communications bus like USB or LAN and then utilizing code entered via a software layer (like LabVIEW, .NET, Python, etc..) to sequence the specific instrument commands and process data.

In this note, we are going to show how to use Python to create a communications link between an instrument and a remote computer using a LAN connection. Once the connection is verified, you can begin to work on the control software.

NOTE: This example requires open sockets on the instrumentation. At this time, not all SIGLENT products feature open sockets. Check the product page FAQs or with your local SIGLENT support office for more information.

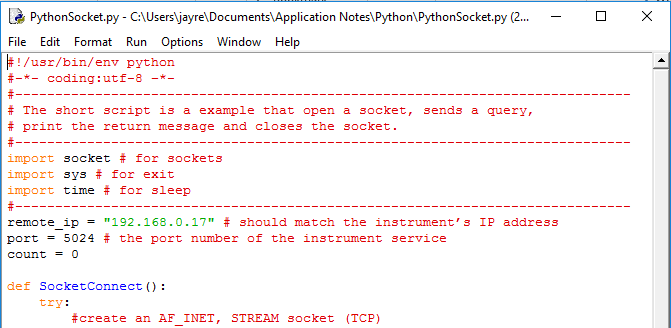

Python is an interpreted programming language that lets you work quickly and is very portable. Python has a low-level networking module that provides access to the socket interface. Python scripts can be written for sockets to do a variety of test and measurements tasks.

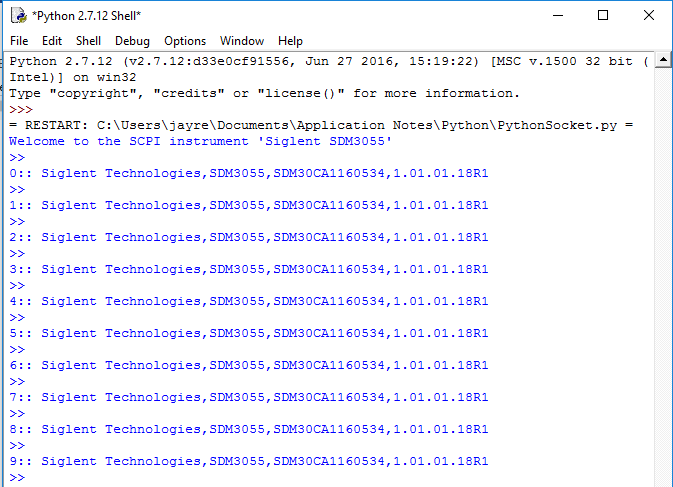

Here is a Python 2.7 script that opens a socket, sends a query and closes the socket. It performs this operation in a loop 10 times:

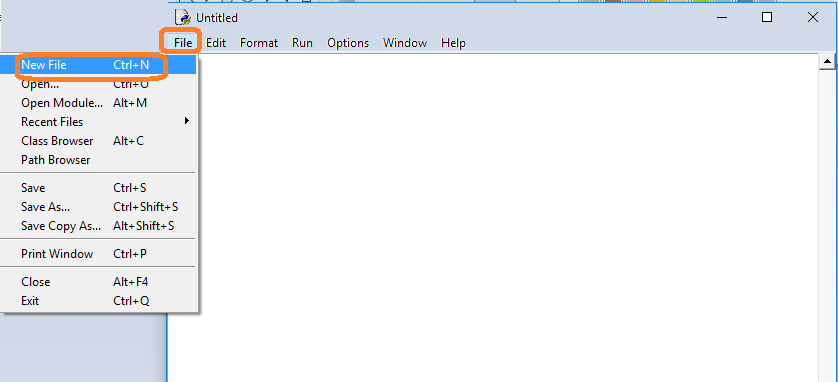

You can follow the instructions below to build your own example:

1. Power on and connect the instrument to the network via LAN

2. Verify that the Gateway, Subnet Mask, and IP address of the instrument are valid for the network you wish to use. This information is typically located in the System Information or IO menu. See the specific instrument user’s guide for more information on LAN settings.

3. Download python and your favorite python editor (I use IDLE):

https://docs.python.org/2/library/idle.html

Start your python editor:

5. Open a new file by pressing File > New File.. and name the file

6. Copy and paste the code at the end of this note into the file editing window:

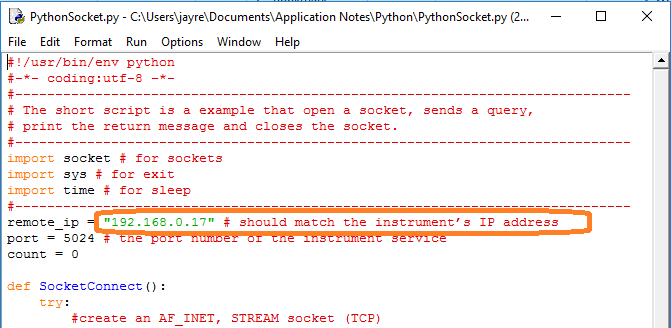

7. Change the IP address and port number so that they match the IP address and port for the instrument you wish to connect to:

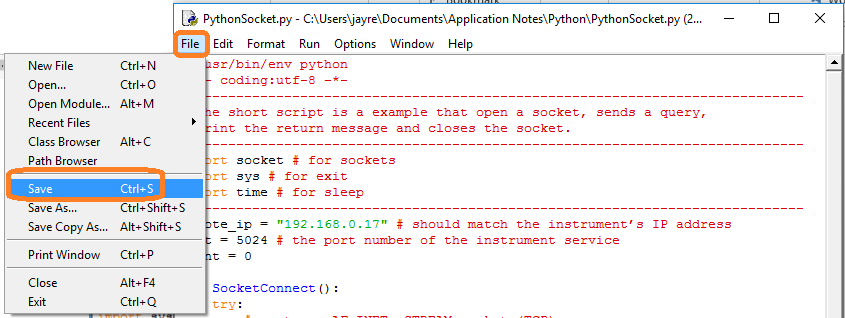

Save the file:

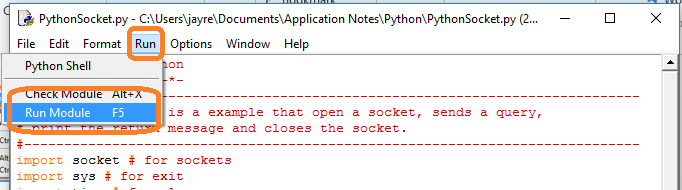

8. To Run, select Run and Run Module:

Verification of a LAN connection using Telnet

Automating a test can dramatically increase the productivity, throughput, and accuracy of a process. Automating a setup involves connecting a computer to the test instrumentation using a standard communications bus like USB or LAN and then utilizing code entered via a software layer (like LabVIEW, .NET, Python, etc..) to sequence the specific instrument commands and process data.

This process normally goes quite smoothly, but if there are problems, there are some basic troubleshooting steps that can help get your test up-and-running quickly.

In this note, we are going to show how to use Telnet to test the communications connection between an instrument and a remote computer using a LAN connection to ensure that it is working properly. Once the connection is verified, you can begin to work on the control software.

Telnet provides a means of communicating over a LAN connection. The Telnet client, run on a LAN connected computer, will create a login session on the instrument.

NOTE: The Telnet connection requires open sockets on the instrumentation. At this time, not all SIGLENT products feature open sockets. Check the product page FAQs or with your local SIGLENT support office for more information.

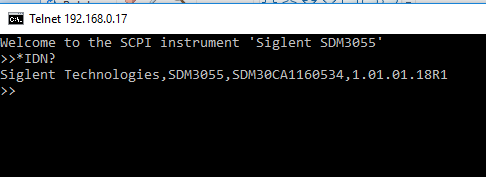

A connection, established between the computer and instrument, generates a user interface display screen with SCPI> prompts on the command line.

Using the Telnet protocol to send commands to the instrument is similar to communicating with USB. You establish a connection with the instrument and then send or receive information using SCPI commands. Communication is interactive: one command at a time.

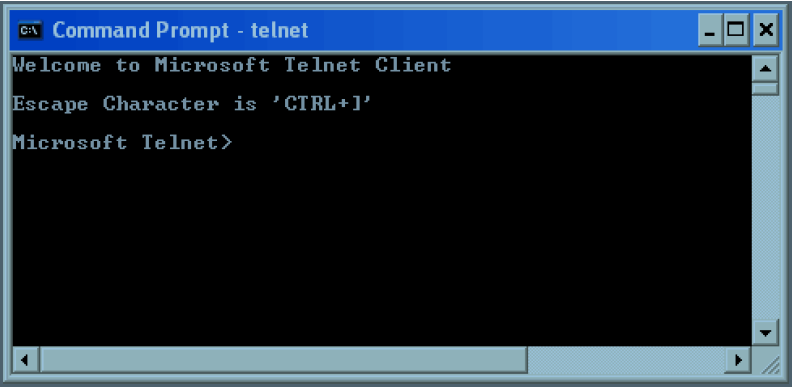

The Windows operating systems use a command prompt style interface for the Telnet client.

STEPS

1. Power on and connect the instrument to the network via LAN

2. Verify that the Gateway, Subnet Mask, and IP address of the instrument are valid for the network you wish to use. This information is typically located in the System Information or IO menu. See the specific instrument user’s guide for more information on LAN settings.

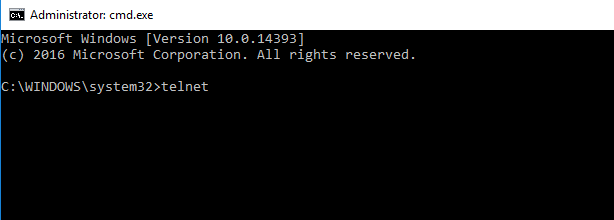

3. On the computer, click Start > All Programs > Accessories > Command Prompt.

4. At the command prompt, type in telnet.

5. Press the Enter key. The Telnet display screen will be displayed.

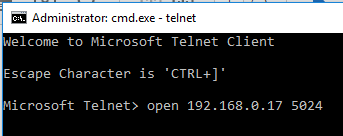

6. At the Telnet command line, type: open XXX.XXX.XXX.XXX 5024 where XXX.XXX.XXX.XXX is the instrument’s IP address and 5024 is the port. You should see a response similar to the following:

7. Now, you can enter any valid command for the specific instrument that you are controlling. See the specific programming guide for the instrument for more information.

This is especially helpful when you are planning a specific test sequence, the effect of delays/timing, or troubleshooting a command. You can send each command one-at-a-time and check the performance of the instrument.

*IDN? is a common identification string query (question or information request) that returns the information from the connected instrument

Measuring Power Supply Control Loop Response with Bode Plot II

Stability is one of the most important characteristics in power supply design. Traditionally, stability measurements require expensive frequency response analyzers (FRA) which are not always available in a laboratory. Now, using a Siglent oscilloscope, like the SDS1204X-E with the newly released Bode Plot Ⅱ software, together with a Siglent arbitrary waveform generator (SDG or SAG) and a Picotest injection transformer, the measurement can be made.

In this application note, we will show you the basic principles for making this stability measurement and how to use these instruments to make the measurement.

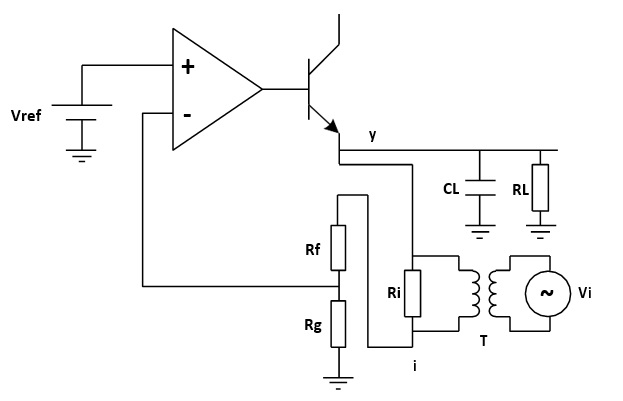

Figure 1: Bode II setup

Figure 1: Bode II setup1. Basic Principle of Stability Measurement

1.1 Stability of The Feedback System

A regulated power supply is actually a feedback amplifier with a large amount of current sourcing capability. Any theory that applies to a basic feedback amplifier also applies to a regulated power supply.

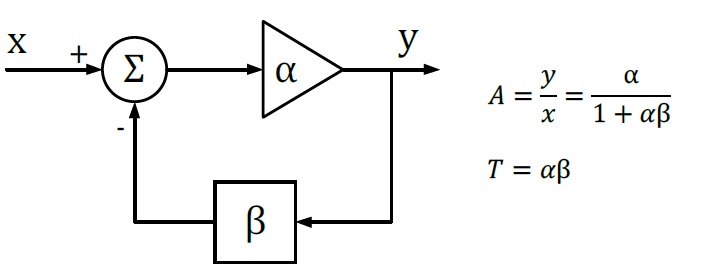

In feedback theory, the stability of a feedback system can be determined by evaluating the loop transfer function. A more practical way is to measure the bode plot of the loop gain. Figure 2 shows a typical feedback system.

The closed loop transfer A is the mathematical relationship between input x and output y. The loop gain T, by its name, is defined as the gain of a signal traveling around the loop.

Figure 2: Typical Feedback Loop

Figure 2: Typical Feedback LoopSince α and β are complex variables, they have not only magnitude but also phase angle, as also does the loop gain T. If the phase angle of T reaches -180° while the magnitude is 1, the closed-loop transfer function A becomes infinity. In this situation, the system will maintain an output signal while there is no input. Thus, the system acts as an oscillator rather than as an amplifier, which means that the system is not stable.

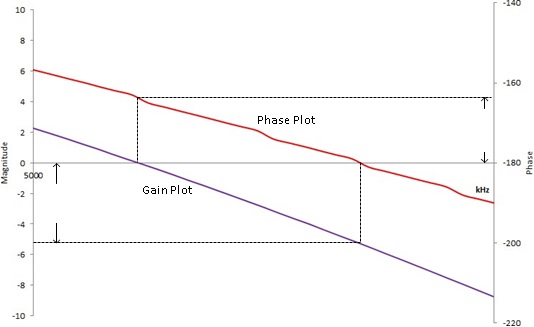

If we plot the loop gain in a bode plot, we can evaluate the stability by finding the phase margin and gain margin. A phase margin is defined as how many degrees the phase can be decreased before reaching -180°while the magnitude is 1 (or 0 dB). The gain margin is defined as how many dB in magnitude can be added before reaching 1 (or 0 dB) while the phase is -180°.

Figure 3: Bode Plot, phase, and gain margin

Figure 3: Bode Plot, phase, and gain margin1.2 Break the Loop

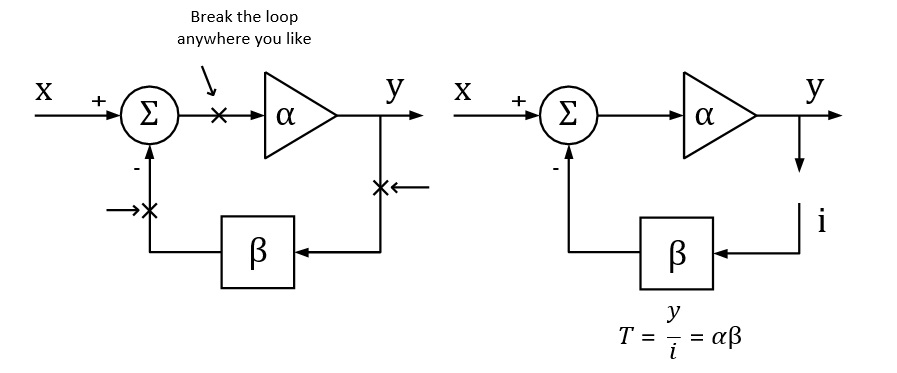

To get the desired loop gain, we simply break the loop. Figure 4 shows how to break the loop in a typical feedback system. Technically you can break the loop any place you like. We commonly choose to break the loop at the point between the amplifier output and the feedback network. Then we insert a test signal i to travel around the loop. The loop gain is the mathematical relationship between the output y and the test signal i.

Figure 4: Breaking the loop in a typical feedback system

Figure 4: Breaking the loop in a typical feedback system1.3 Loop Injection

In reality, we can never really break the loop because the feedback loop serves to maintain the DC quiescent operation point of the circuits. Without the feedback loop, the device under test will become saturated because of the small input offset voltage, and then no useful result can be measured.

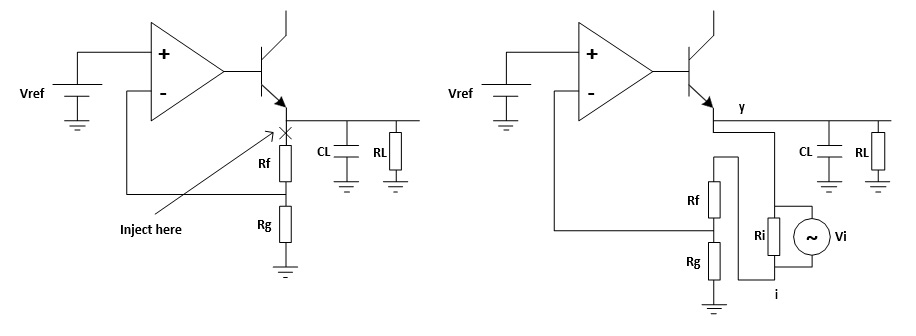

To overcome this, we should measure the open loop response inside a closed loop. Therefore, we just inject a signal to the loop rather than breaking the loop. Figure 5 shows a typical method of loop injection. The injection point is chosen so that the impedance looking in the direction of the loop is much higher than that looking backward. One possible point is between the output and the resistor divider feedback network. Other points that meet this requirement may be chosen.

Figure 5: Loop injection

Figure 5: Loop injectionTo maintain the closed loop, a small injection resistor Ri is inserted at the injection point. The resistor should be small enough so that it will have little effect on the circuit and also the lower the resistor value the lower the frequency the transformer will operate. Picotest recommends a resistor value of 4.99 Ω for the J2100A, and larger value may be chosen depending on the circuits. The injection signal is then applied across the injection resistor.

The signal injected should have no effect on the DC operating point of the circuit. A method to solve the common ground connection problem is to use an injection transformer as shown in Figure 6.

Figure 6: Injection Transformer

Figure 6: Injection TransformerThe injection signal starts at one end of the injection resistor, travels through the resistor divider feedback network, the error amplifier and the pass element transistor and finally to the output, which is the other end of the injection resistor. The relationship between the injection signal i and the output signal y is the loop gain that we wish to measure.

Be aware that we are measuring an open loop parameter inside a closed loop, the phase starts at 180°and decreases to 0°, rather than starting at 0°and decreasing to -180°. So the phase margin should be measured relative to 0°.

2. Measurement Setup and Result

2.1 Equipment

Oscilloscope: Siglent SDS1204X-E with firmware version higher than 6.1.27R1 (Bode Plot Ⅱ release)

Signal Source: Siglent SDG2042X

Power Supply: Siglent SPD3303X

Probe: Siglent PP215 passive probe switched to 1X

Injection Transformer: Picotest J2100A

Device-Under-Test: Picotest VRTS v1.51

2.2 Circuit Connection

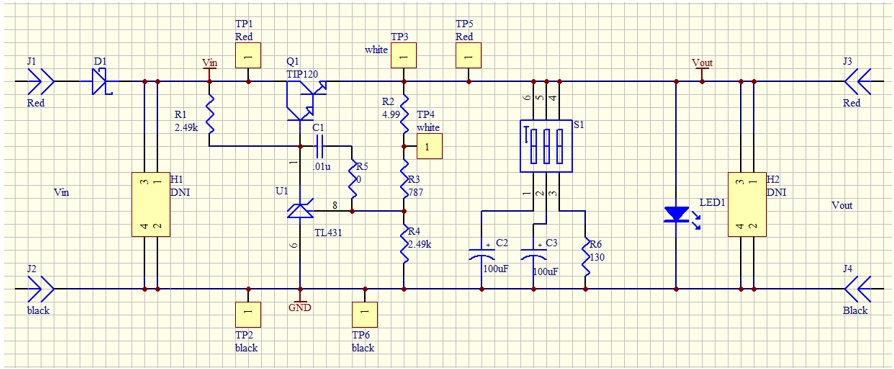

The Picotest VRTS v1.51 is a demonstration board for voltage regulator testing. Technically it is a linear regulator built from the famous TL431 and a discrete transistor. The schematic is shown in Figure 7. Different output capacitors can be selected to see the impact on the control loop stability.

Figure 7: VRTS v1.51 schematic

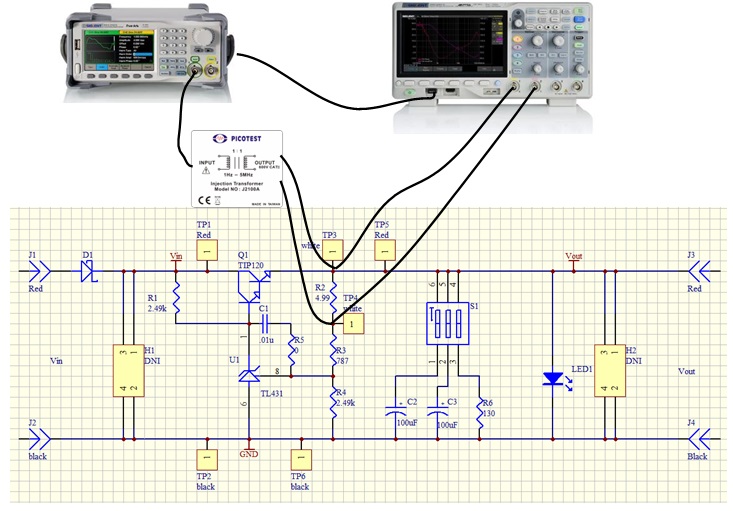

Figure 7: VRTS v1.51 schematicFor the propose of our power supply control loop response measurement, the injection point is TP3 and TP4. The circuit connection is shown in Figure 8.

The generator is connected to the oscilloscope through USB (connection through Ethernet is also supported).

The injection transformer is connected in parallel with the injection resistor so that the signal is injected to the loop while preventing the circuit DC operation point from being affected by the generator.

The TP3 and TP4 points are also connected to the oscilloscope, and the TP4 is defined as the DUT Input while the TP3 is the DUT Output in the Bode Plot Ⅱ.

Figure 8: Circuit connection

Figure 8: Circuit connection Figure 9: Probe and Transformer connections to the DUT

Figure 9: Probe and Transformer connections to the DUT2.3 Instrument Configuration

In this section, we will show how the key configuration should be made in order to make the measurement correctly. For complete instructions to the Bode Plot Ⅱ, please refer to the user manual and the quick start guide.

Before entering the Bode Plot Ⅱ, it is recommended that you enable the oscilloscope’s 20 MHz bandwidth limit setting.

At this time, we want to measure the bode plot from 10 Hz all the way to 100 kHz. This frequency range should be enough for a circuit with an expected crossover frequency at about 10 kHz.

Enter the Config menu and set the Sweep Type to Simple, then enter Set Sweep to set the sweeping frequency. Set the Mode to Decade and Start to 10 Hz, Stop to 100 kHz. Set Points/dec to 20, enough for a typical sweep. Enter the Set Stimulus menu to set Amplitude to 50 mV. Enter the Set Channel menu to set DUT Input to CH1 and DUT Output to CH2.

Figure 10: Bode II scope configuration

Figure 10: Bode II scope configuration2.4 Results and Data analysis

After the configuration is done, return to the main menu and press Run to start the sweep.

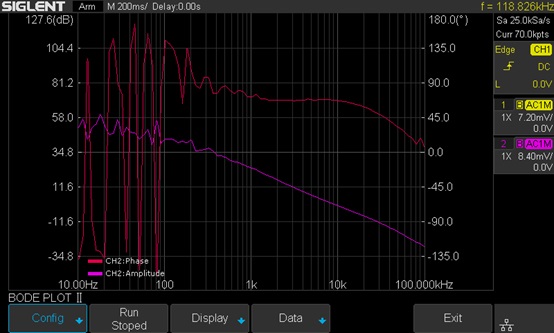

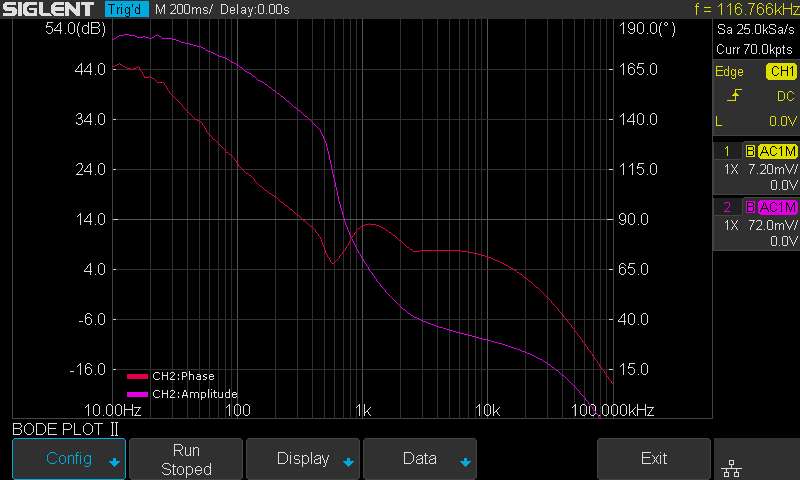

Wait to see the results as shown in Figure 11.

The result is somewhat confusing and suspect because of the trace at low frequency, especially the phase trace, alternating up and down. We will introduce a method called Vari-level to resolve this problem in the next section.

Figure 11: Measurement results

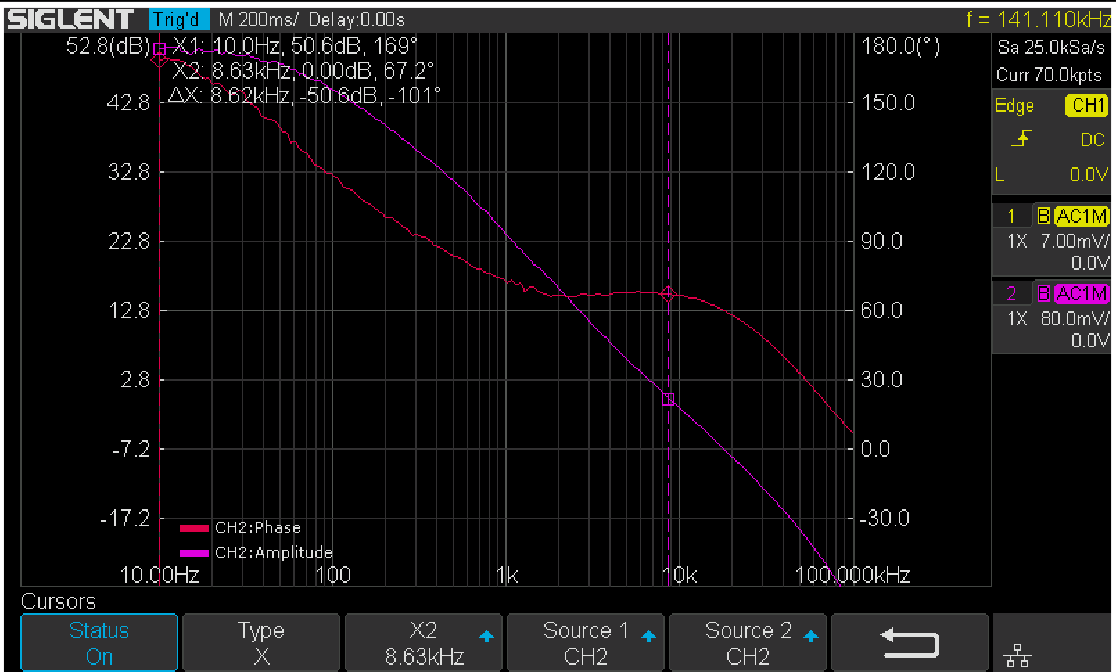

Figure 11: Measurement resultsAfter the sweep has completed, press Run again to stop the sweep. Enter the Display menu and then enter the Cursors menu to turn on the cursors. Use the Adjust knob to move the cursors and set the phase margin as shown in Figure 12.

Figure 12: Cursor measurement on the Bode plot

Figure 12: Cursor measurement on the Bode plotYou can also turn on the List feature in the Data menu to examine the measured data, or you can export the data to an external USB FLASH driver for further analysis on a computer.

Figure 13: Exporting data

Figure 13: Exporting data2.5 Vari-level

In the previous section, we can see that the results are not ideal, for the bouncing trace at low frequency. This is because at low frequency the amplitude difference between the input and output channel is relatively large, and since we are using a relatively small stimulus signal (this time 50 mVpp), the signal presented at the DUT Input channel is extremely small so that a commercial general propose oscilloscope cannot measure it accurately.

But we cannot simply increase the stimulus’ signal amplitude. The result will be similar to what is shown in Figure 14. The large signal near the crossover frequency region causes serious distortion to the loop. The distorted signal in the time domain is shown in Figure 15.

Remember that a bode plot only makes sense in a linear system, and has no meaning in a heavily non-linear system. The result is useless.

Figure 14: Increased stimulus signal amplitude and distortion

Figure 14: Increased stimulus signal amplitude and distortion Figure 15: Distortion in the time domain

Figure 15: Distortion in the time domainOne possible solution to the problem is Vari-level (other manufactures may call it “Shaped Level” or “Level Profile”). The Vari-level concept is simple: The stimulus signal amplitude is variable over the frequency. If we use a large signal at low frequencies, and decrease the amplitude to a fairly small level near the crossover region so that it causes little distortion to the loop, in theory, we can get an ideal result.

Under the Configure menu, set Sweep Type from Simple to Vari-level, and push Set Vari-level to enter the Vari-level profile editor.

Figure 16: Set Sweep Type to Vari-level

Figure 16: Set Sweep Type to Vari-levelFigure 17 shows the Vari-level profile editor. The Profile option allows the user to select and save up to 4 profiles. The Nodes sets the number of nodes in the profile trace, the minimum allowed number of nodes is 2 because at least 2 points can determine a line, and always the first and the last node set the start and stop of the trace. Press Edit Table will enter the profile editor mode. The parameter under editing is highlighted by cursors, and next push Edit Table again to cycle the cursors between “Freq”, “Ampl” and the entire row, which allows the user to navigate through the entire table. Users can use the Adjust knob to set the highlighted parameter, and pushing the knob will call out a visual keypad which allows direct input to the parameter. The Set Sweep and Set Stimulus option is somewhat similar to that in the Simple type of sweep, but they are not correlated. This time we set the sweep Mode to Decade and a 40-point-per-decade is sufficient. The profile shown in Figure 17 is used in this measurement. It is not the optimum profile for this circuit but should be a good place to start.

Figure 17: Vari-level profile editor

Figure 17: Vari-level profile editorIn practice, one should always experiment with those parameters to find an optimum solution for a particular circuit.

One practical way to do this is to monitor the signal in the time domain, decrease the amplitude of the stimulus signal until no visible distortion can be observed, then decrease the amplitude by another 6 dB. Next, record the amplitude and frequency, jump to another frequency and repeat the process.

There is a better way to find the optimum profile if you already have a known good profile. Reduce the signal amplitude by 6 dB and run a sweep to see if the plot changes. If it does change, reduce the amplitude by another 6 dB and sweep again. Until the result doesn’t change, then you can increase the amplitude by 6 dB and that’s an optimum profile. This is time-consuming but necessary to get a meaningful result.

Once profile editing is completed, return to the main menu and push Run to start the sweep. Figure 18 shows the final result of the measurement with Vari-level. Changing the capacitor selection switch S1 on the VRTS v1.51 demo board will alter the loop response due to the impact of different capacitors.

Figure 18: Results with Vari-level

Figure 18: Results with Vari-level3. Summary

The Siglent oscilloscope with newly released Bode Plot Ⅱ together with a Siglent signal generator and a Picotest injection transformer offer a very flexible and easy-to-use power supply control loop measurement system.

Using EasyScope X to retrieve Average Waveform Data

Waveform averaging can be a useful method to decrease noise in a particular signal.

The SIGLENT SDS series of oscilloscopes can easily collect average waveform data using EasyScope X software.

NOTE: At this time, average waveform data is not able to be saved in CSV format via the front panel USB connection to a USB memory stick.

Initial Setup

– Download NI-VISA Runtime Engine that matches your operating system, if your computer does not already have the VISA library.

It can be downloaded from National Instruments: https://bit.ly/2pw5gQW

– VISA library installed. This is the communication library used by EasyScope X software to communicate with the instrumentation

– Download EasySpectrum Software from the SSA3000X Product Page on the SIGLENT America website: https://bit.ly/2okc8wG

Connect and Collect

1. Connect the scope to the computer using a USB or LAN connection and power it on.

NOTE: This example uses a USB connection for communication between the scope and computer.

2. Open an instance of EasyScopeX by clicking on the desktop icon:

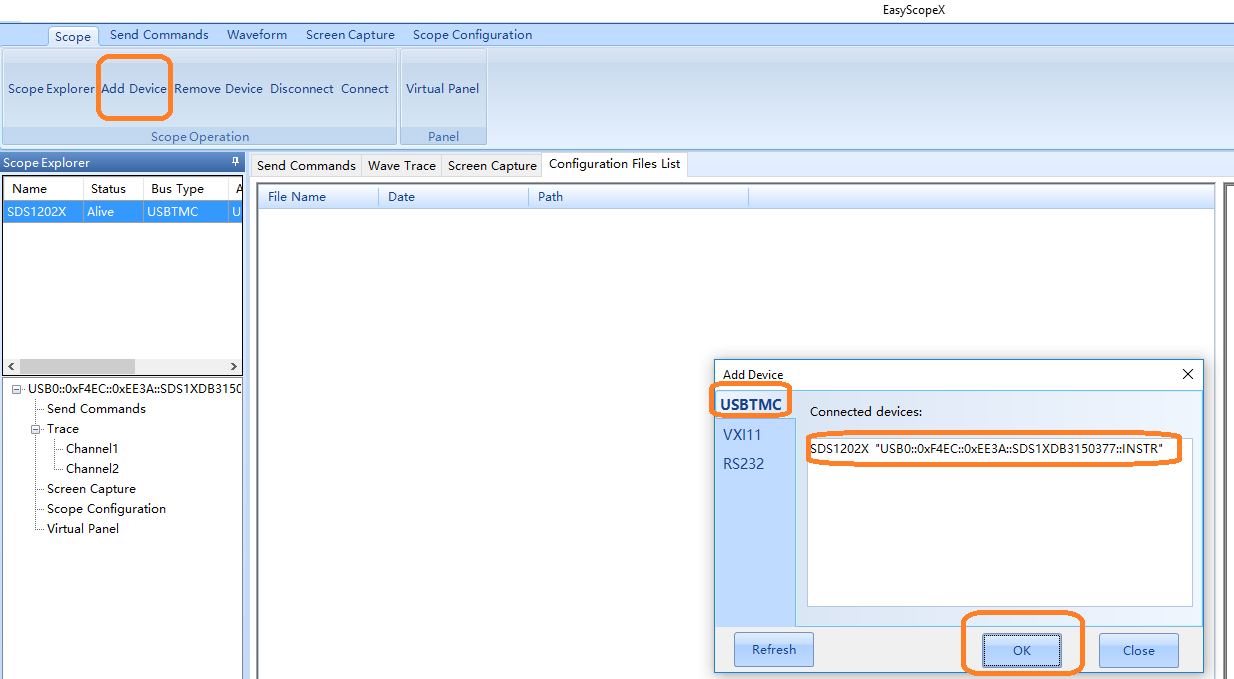

3. Add Device and select the session address for the instrument you wish to connect:

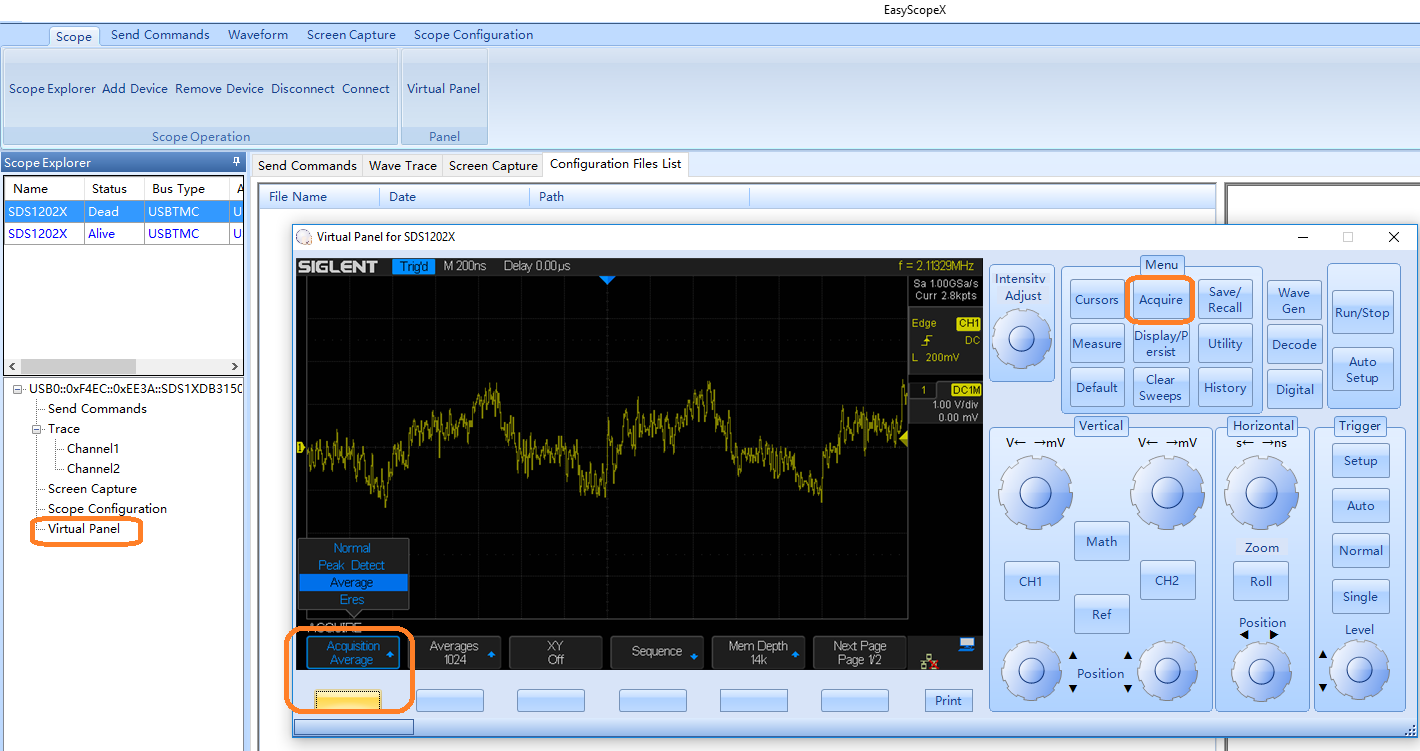

4. Configure the instrument to capture the signal of interest. You can perform this manually on the front panel, or you can use the Virtual Panel control.

Select Virtual Panel > Acquire > and press the button labeled Acquisition until the type = Average:

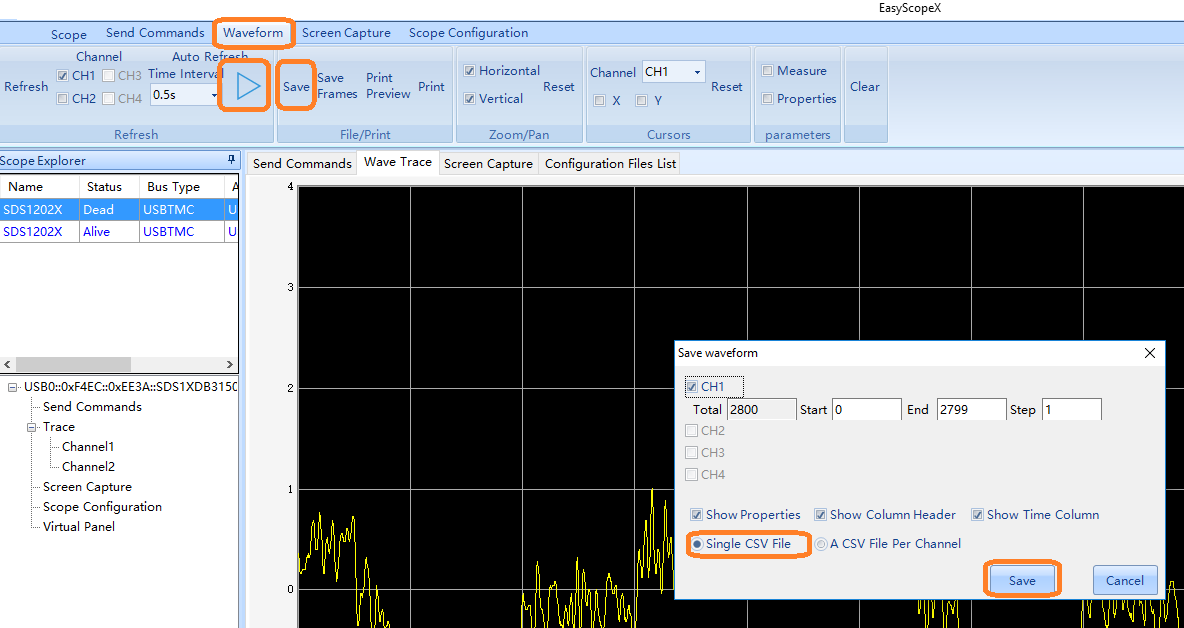

5. Select Waveform, and use the Play/Pause button to acquire the waveform of interest. Then, select Save > select the channel of interest > select the type of CSV to save > Press Save to open a file dialog box.

Quick remote computer control using LXI Tools

Introduction:

There are many options for people considering remote communication and control of test and measurement instrumentation. In most cases, a computer is used to communicate to test instrumentation using USB or LAN connections. The computer can configure the instruments, collect and organize data, and present it in a useful and flexible way.

Remote control provides:

- Increased repeatability: The instrumentation is set up the same way, every time.

- Efficient data collection: Data can be automatically filtered and stored.

- Easily configure the test system parameters: Each command is executed in the same order and in the same timeframe.

- Quickly visualize system performance: Graphical or tabular data formatting is easy.

There are numerous platforms (Windows, Linux, etc..) and software programs (LabVIEW, .NET, Python) available to build automated test systems. The right choice for your application is highly dependent on your needs and the available skills you have.

In this note, we are going to discuss how to use LXI Tools to communicate with SIGLENT instrumentation. LXI Tools is an open source software application that uses the local area network (LAN) connection to quickly control remote instrumentation. It is easy to install, has a small operating footprint, and is really powerful while being quite easy to use. Let’s start by looking at the basics.

You can also see the video version of this note here: https://siglentna.com/video/lxi-tools/

Why Open Source?

Open source coding is a community-based development style in which a group of contributors work together to build and maintain programs using shared code and components. In this way, a platform can be built and tested quickly and may cost significantly less than commercial programming environments. LXI Tools is free open source software and the project welcomes new contributors that would like to help improve the tools.

Here is a link to the LXI Tools website: https://lxi-tools.github.io

Why LXI Tools?

LXI-Tools is a collection of open source software tools that provide direct control of LXI compatible instruments such as modern oscilloscopes, power supplies, spectrum analyzers, and more.Simply install LXI Tools, connect your instrument, and start communicating.

It really is that easy.

LXI-Tools Provides:

- Quickly discover the available instruments on the LAN

- Retrieve copies of the displayed images (quickly see signals, data, and instrumentation setups) and convert image file types

- Benchmark LAN performance

- Send individual commands to an instrument to perform simple test actions. For example, you could return the measured data from a DMM.

To learn more about LXI-Tools, please see https://github.com/lxi-tools/lxi-tools

Instructions:

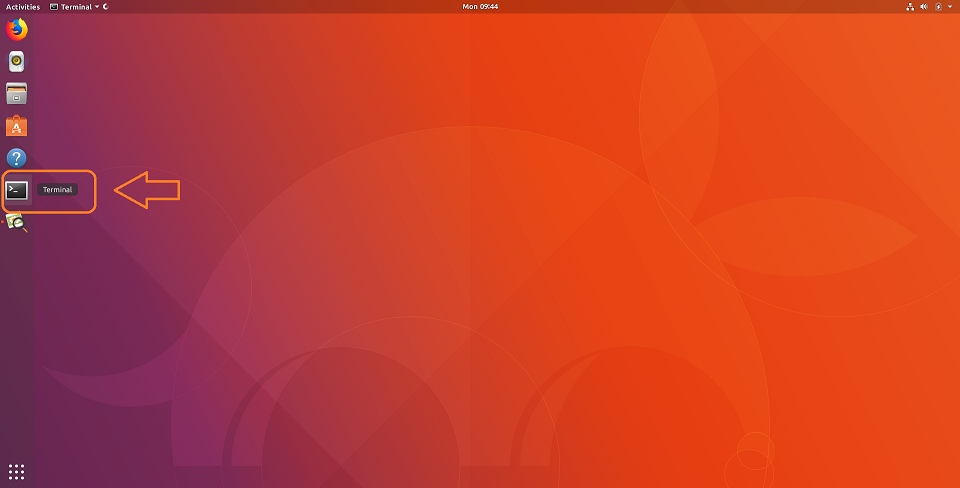

- Install the appropriate version of LXI-Tools for your operating system

2. Open a terminal. In this example, I am using Ubuntu (17.10) running on a virtual machine hosted by a Win 10/64 bit OS.

To learn more about the virtual machine used in this example:https://www.virtualbox.org/

The OS is Ubuntu: https://www.ubuntu.com/

3. Once loaded, startup Linux:

With Ubuntu, you can use Snap to install:

$ snap install lxi-tools

LXI Discover:

Quickly searches the LAN for instruments and lists their identification string and IP address.

Plug in and power on your instrumentation and make sure that they are connected to a working LAN connection. You can manually check the instrument IP address and save this info to compare to later steps.

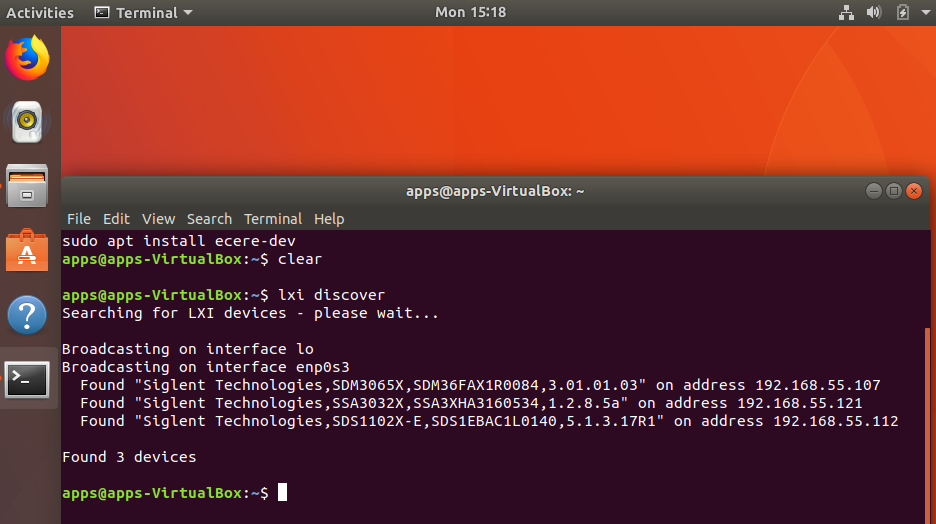

Open up a terminal window. At the “$” prompt, simply type lxi discover… LXI tools will search the LAN for connected instruments.

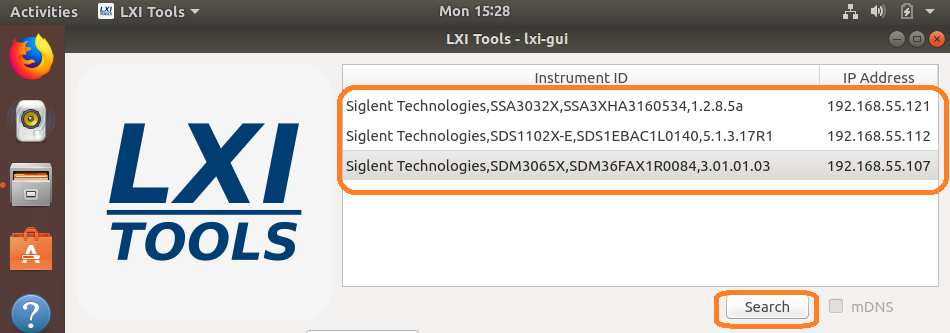

Here, we have three devices connected: an SDM3065X, SSA3032X, and an SDS1102X-E (which has been superseded by the SDS1202X-E series here in North America). It also includes the instrument serial number, firmware revision, and IP address.

NOTE: This has been tested with a large number of instruments, but may not be supported by some. There is a list of compatible instruments at the end of this note or you can check LXI-Tools support for the latest list of supported products.

Screenshot:

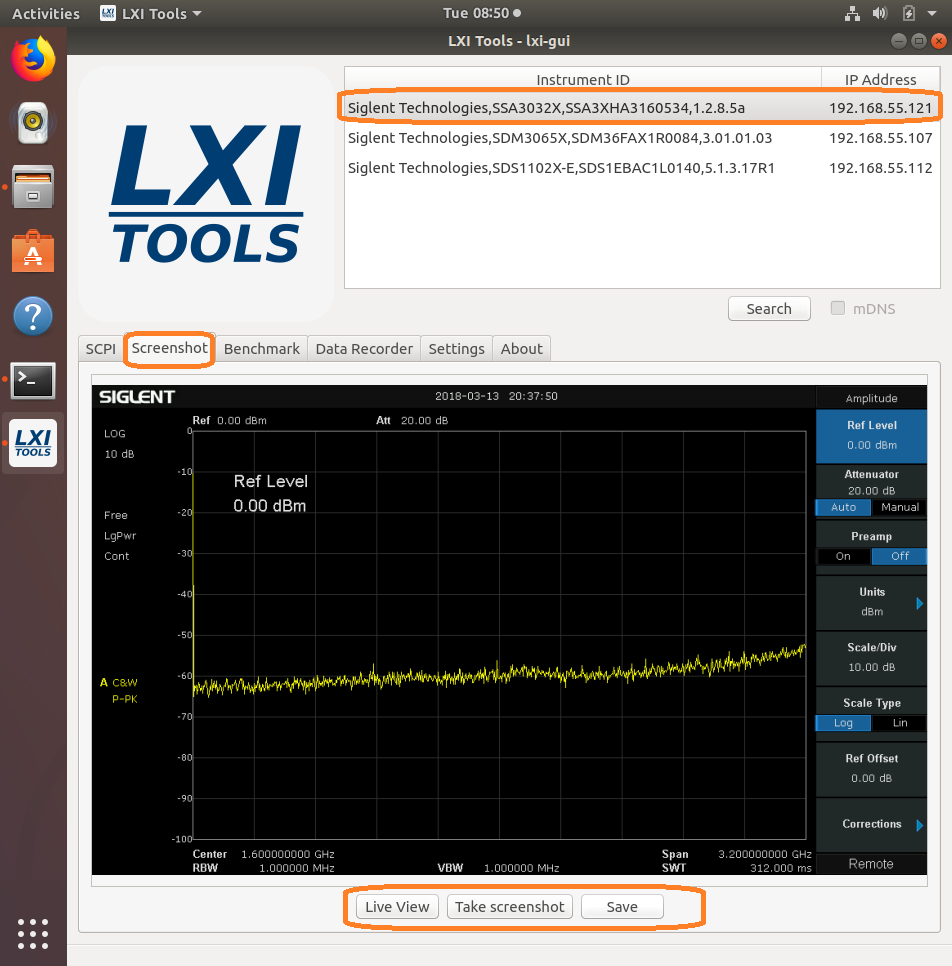

This function retrieves a copy of the instrument display and saves it to the local drive. This is ideal for adding information to reports and sharing events with colleagues.

Type “lxi screenshot – – address <device address>”

NOTE: There should be two “-” with no spaces before “address” for every command.

Image Edits using ImageMagicks

Use ImageMagick® to create, edit, compose, or convert bitmap images. It can read and write images in a variety of formats (over 200) including PNG, JPEG, JPEG-2000, GIF, TIFF, DPX, EXR, WebP, Postscript, PDF, and SVG. Use ImageMagick to resize, flip, mirror, rotate, distort, shear and transform images, adjust image colors, apply various special effects, or draw text, lines, polygons, ellipses and Bézier curves.

For more information, visit… https://www.imagemagick.org/script/index.php

$ lxi screenshot –address <ip> – | convert – screenshot.jpg

$ lxi screenshot –address <ip> – | convert – screenshot.tiff

$ lxi screenshot –address <ip> – | convert – screenshot.bmpBenchmark:

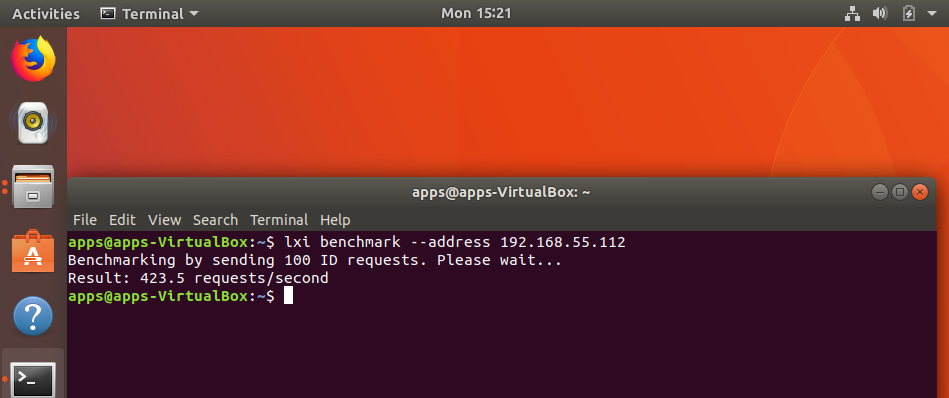

The benchmark command sends 100 requests via LAN and measures the average response time of the instrument. It can be used as a gauge for the health of the connection. Higher response rates = faster links.

$ lxi benchmark –address <ip>

Manual vs. Auto-load:

The commands can also be manually or auto-loaded:

Auto-load/detect:

$ lxi screenshot –address 10.0.0.42

Vs. manually specifying which screenshot plugin to use:

$ lxi screenshot –address 10.0.0.42 –plugin siglent-ssa3000x

The only advantage of manually specifying which plugin to use it that it is a bit faster because it does not go through the instrument auto detection steps (retrieve ID, parse regex rules to match correct plugin etc.).

Sending instrument specific commands:

You can also use the SCPI command to send any command to the instrument.

Note that if you have an SCPI command with spaces you must remember to send the specific command in quotes like so:

$ lxi scpi –address 192.168.55.113 “MEAS:VOLT? CH1”

This way the tool knows how to parse the full SCPI string.

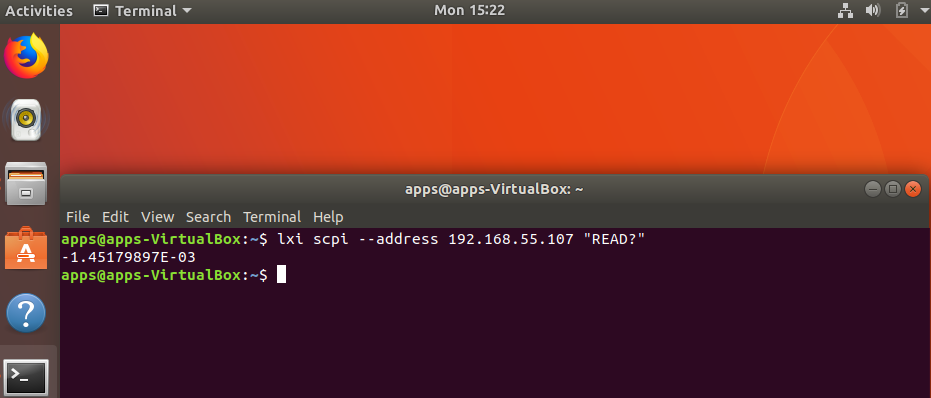

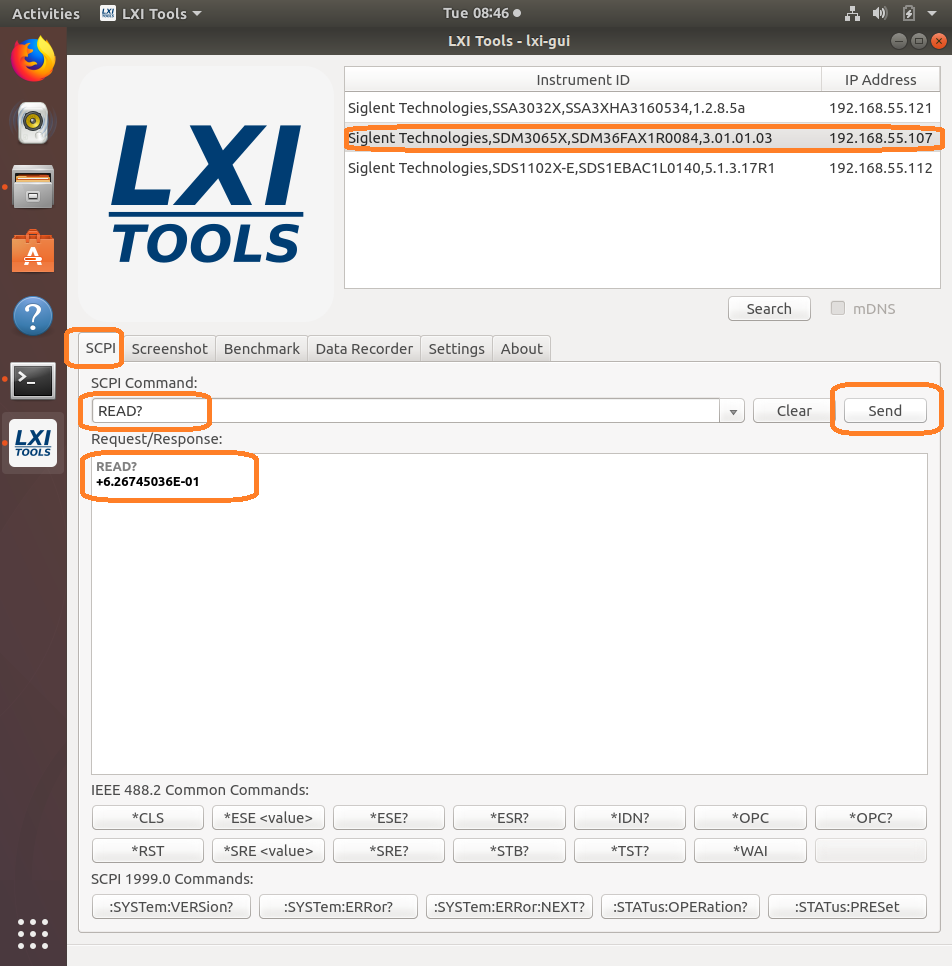

In this example, we send the “READ?” command to an SDM and return a reading:

GUI

Another really great feature is the GUI for LXI Tools. This allows you easy access to discovery of instruments on the network as well as some powerful tools for data capture and instrument control.

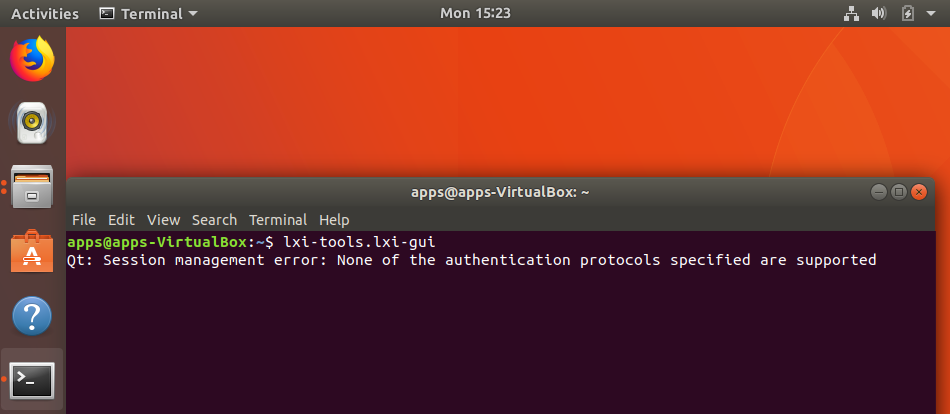

$ lxi-tools.lxi-gui

This adds a very simple yet powerful graphical interface for the LXI tools program:

NOTE: Ignore the “Qt” error shown.

This opens a clean control window:

- Search: Discover the instruments connected to the LAN. Here, we have three instruments connected:

- SCPI command line: Send instrument specific commands. Click on the instrument you wish to communicate with and then enter the command. For queries (commands that require an instrument response, or read function), the returned string will be shown in the text box:

NOTE: The specific commands that can be used are available in the instrument programming guide. Check out the specific instrument documentation for more details.

This tool can be helpful when trying out specific sequences of commands. You can send them one-at-a-time and then observe the instrument functionality.

- Screenshot: Capture and save an image from the instrument. This also features a “live” button that will continuously poll the instrument.

After saving, you can recall the image:

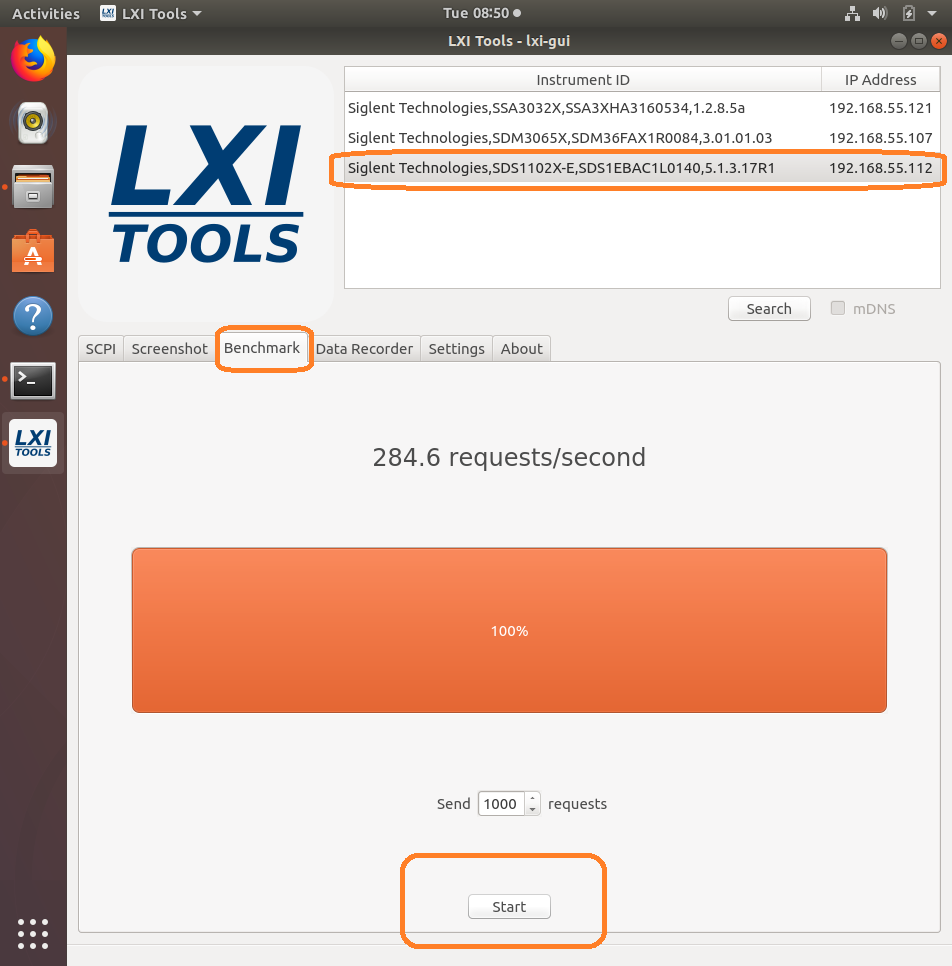

- Benchmark: Checks the performance of the LAN connection by sending a series of commands and measuring the response time. Larger “requests/second” = greater possible bus performance.

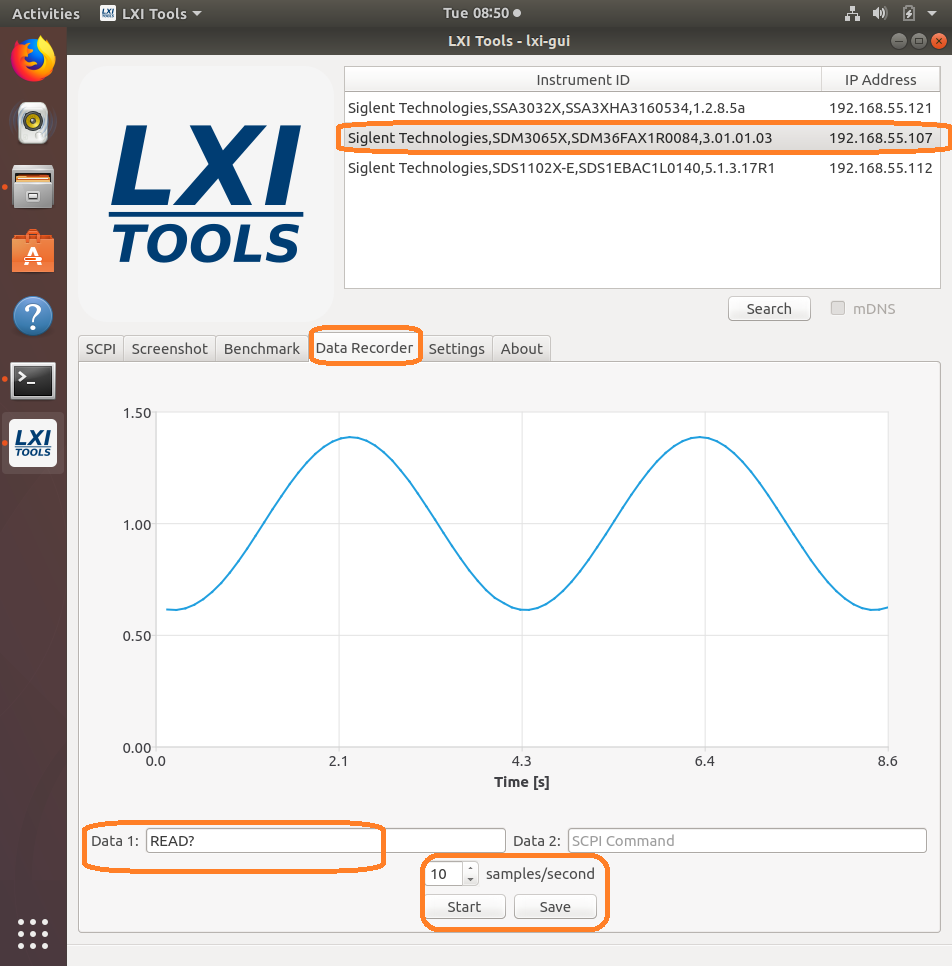

- Data Recorder: Sends the user-defined command a number of times/second and attempts to graph the data. Be aware that data can be returned in different formats and at different rates depending on device configuration. Going faster can make the system unstable and could cause a crash or hang-up.

And the data:

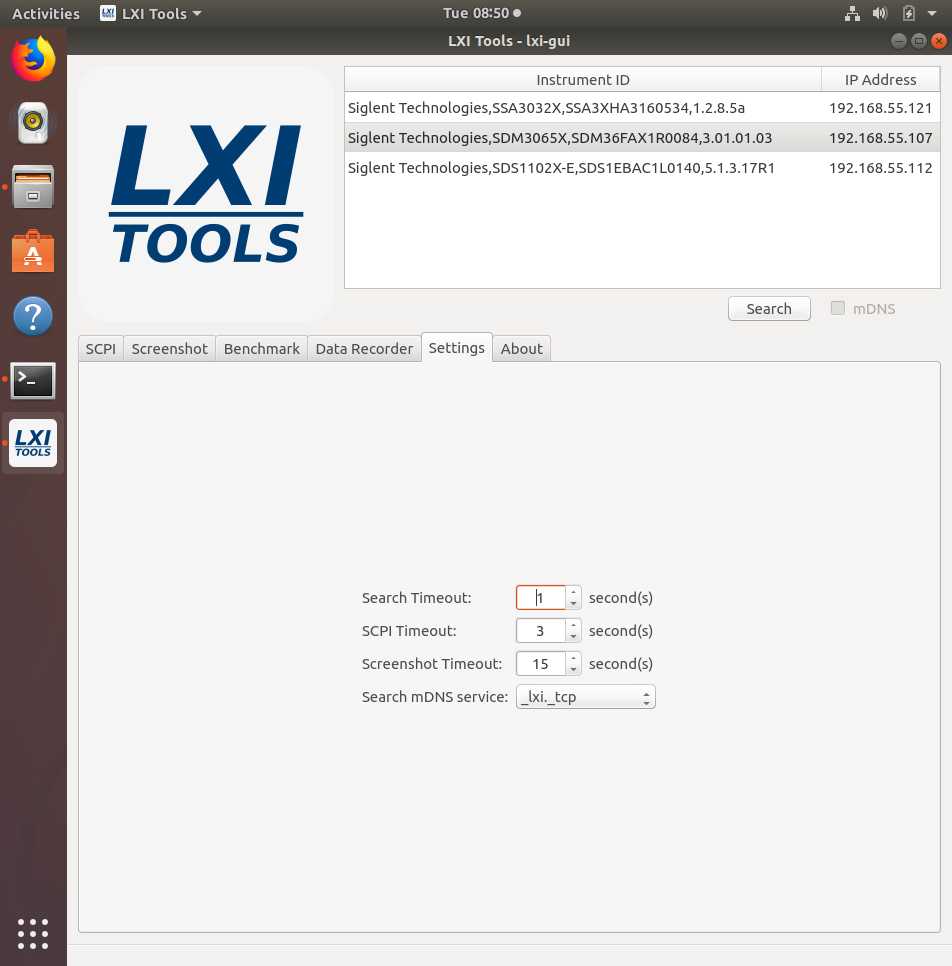

- Settings: Configure the timeouts and other controls.

- About: Version info.

*Here is a list of the latest compatible instruments tested with Lxi-Tools (03/13/2018)

SSA3000X Series:

SSA3000X (Latest 1.2.8.5a)

SDS1000X-E Series:

SDS1202X-E (Older 5.1.3.8R2)

SDS1202X-E (Latest 5.1.3.13)

SDS1204X-E (Latest/first production release 7.6.1.12)

SDS1000X/X+ Series:

SDS1202X+ (Latest 1.1.2.15E3)*

*LIMITED COMMAND SET AVAILABILITY

SDS2000X Series:

SDS2304X (Older 1.2.2.2)*

SDS2304X (Latest 1.2.2.2R10)*

*LIMITED COMMAND SET AVAILABILITY

SDS2000 Series (replaced by the SDS2000X):

SDS2204 (Latest 1.2.2.2)*

*LIMITED COMMAND SET AVAILABILITY

SDM3000 Series:

SDM3045X (Older rev 5.01.01.01)

SDM3045X (Latest rev 5.01.01.03)

SDM3055 (Latest rev 1.01.01.01.19)

SDM3065X (Older rev 3.01.01.02)

SDM3065X (Latest rev 3.01.01.03)

SDG1/2/6X Series:

SDG1032X (Latest 1.01.01.22R5)

SDG20122X (2.01.01.23R7)

SDG6052X (Latest 6.01.01.28R1): 405.3