Your cart is currently empty!

Category: Blog

Blown Fuse Testing Precautions When Using Electronic Load

Blown Fuse Testing Precautions When Using Electronic Load

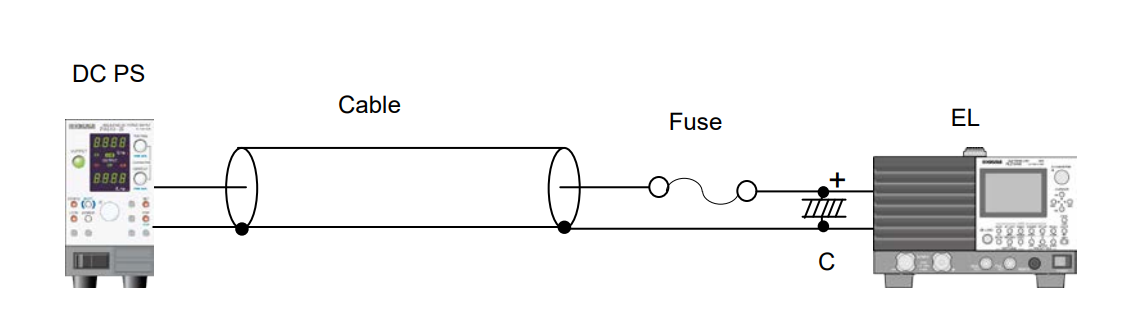

This article will address some precautions on the blown fuse testing such as the unit testing or cable and fuse testing (see Figure 1) and fuse component testing.

1. Test System

A DC power supply, cable, fuse and electronic load are connected as shown in Figure 1.

1) Prepare a DC power supply whose current and voltage capacity are greater than a test range.

2) Set an electronic load to CC mode and set a test current from an electronic load panel.

3) DC power supply: Turn the output on. Electronic load: Turn the load on.

4) Monitor a current with an electronic load ammeter. In general, an electronic load ammeter is more accurate than that of power supply.

Fig. 1

2. Precautions

1) Cable inductance may cause oscillations on electronic loads, especially using longer cables. To prevent it, lower the response speed (RESPONSE) of electronic load (Example for PLZ-4W Series: set RESPONSE to 1/10).

2) If the oscillations persist longer even after lowering the response speed, place an electrolytic capacitor (C = approx. 1000μF) on input terminals of electronic load as shown in Figure 1.

3) Electronic loads can also dynamically change a current (E.g. 0.5A-5A, Duty: 30%, at 200HZ). The rise and fall times vary with the response setting and slew rate setting.Products Mentioned In This Article:

Kikusui’s full range of DC Power Supplies and Electronic Loads please see HERE

How to Measure Output Impedance of Power Supply with Bipolar Power Supply PBZ Series

How to Measure Output Impedance of Power Supply with Bipolar Power Supply PBZ Series

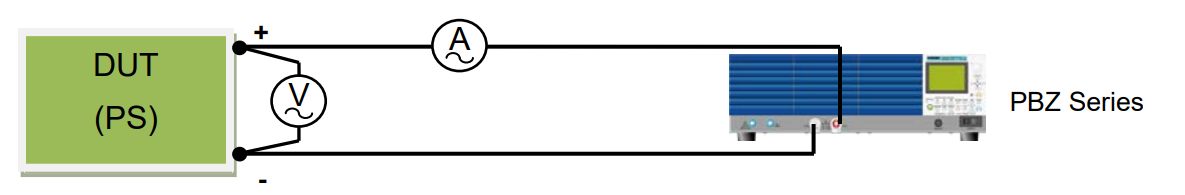

PBZ Series is a bipolar power supply that can be also operated in quadrant 2 to sink the current. This function enables you to measures an output impedance of DUT (e.g. fuel cell, DC power supply) by using PBZ Series as an electronic load. PBZ Series equips with an AC waveform generation function so that you do not need to prepare another oscillator.

The following procedures explain how to flow the load current of DC5A and AC1Arms (1 kHz) to DUT power supply. To accurately measure the impedance, an AC voltmeter and AC ammeter are required.

<Procedures>

1) Reset PBZ to the factory default, if needed. SHIFT+POWER ON

2) Set PBZ to the constant current (CC) mode. Press the CONFIG key (menu page 1/7). MODE

POLARITY: BIPOLAR/UNIPOLAR *Press▼ to move the cursor. Turn the knob to specify the setting. CONTROL: CC

3) Set a DC current on PBZ.

Press the DC key.

DC -5.000A (Note: Negative current should be set.)

4) Set an AC current on PBZ. Press the AC key. FUNC Sine wave

AMPL 2.8 A p-p (AC will flow at 1Arms.) FREQ 1000.00Hz (1 kHz)

AC ON

5) Turn DUT’s output on.

After checking that the negative voltage is applied on the PBZ COM terminal and the positive voltage is applied on the PBZ OUT terminal, turn DUT’s output on.

6) Turn PBZ’s OUTPUT on.

PBZ will sink the current from DUT.

7) Check the current.

Press the MEASURE key.

FUNC DC : Measure DC current/voltage *Turn the knob. FUNC AC : Measure AC current/voltage

8) Turn PBZ and DUT off.

Turn PBZ’s OUTPUT off. Then, Turn DUT’s output off.

Please be noted that the negative voltage might be applied to the DUT by wrong procedures. If the DUT has a diode in parallel with the output, it will be protected that the sink current flows through the diode.Products Mentioned In This Article:

- PBZ Series please see HERE

Vibration Testing Method for Automotive Wiring Harness Connector

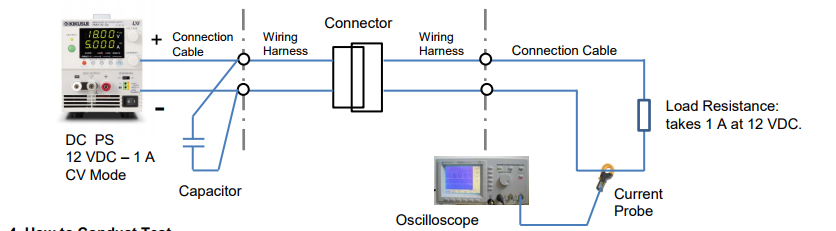

1. Test Condition: Conduct the vibration testing on the automotive wiring harness connector under supplied at 12 VDC/1 A.

2. Test Criteria: If the resistance of the wiring harness connector exceeds 7.0 Ω for more than 1 microsecond (us),

it defines an electrical discontinuity.

3. Test Circuit:

4. How to Conduct Test

• Calculate the resistance of the wiring harness connector based on the current change using Ohm’s law (measure the current and the time interval with an oscilloscope); E.g. If the current changes from 1.0 A to 0.63 A; it would be approx. 7.0 Ω (excluding the resistance of the connection cables).

• If the connection cables are too long from the DC power supply to the wiring harnesses, place a capacitor at their connecting point to reduce the cable’s inductance.

• Operate the DC power supply in constant voltage (CV) mode. Since the voltage is constant, the current depends on the connector’s contact resistance and the load resistance. So, the connector’s contact resistance can be accurately measured.

• The resistance calculation accuracy is affected by the inductance of the wiring harnesses and the connection cables. To minimize the induction effect, make them into a twisted pair and as short as possible.

• Use a non-inductive resistance for the load resistance (Do not use an electronic load instead, otherwise the current cannot be accurately measured.)

• We recommend you to use a current probe for the current waveform observation. If connecting a resistor to observe the waveform, you may not obtain an accurate measurement especially if the voltage becomes lower due to noise generated from the connector.Products Mentioned In This Article:

- PMX Series please see HERE

PBZ Series: How to Output Synchronised Square Wave from TRIG OUT Terminal

PBZ Series: How to Output Synchronised Square Wave from TRIG OUT Terminal

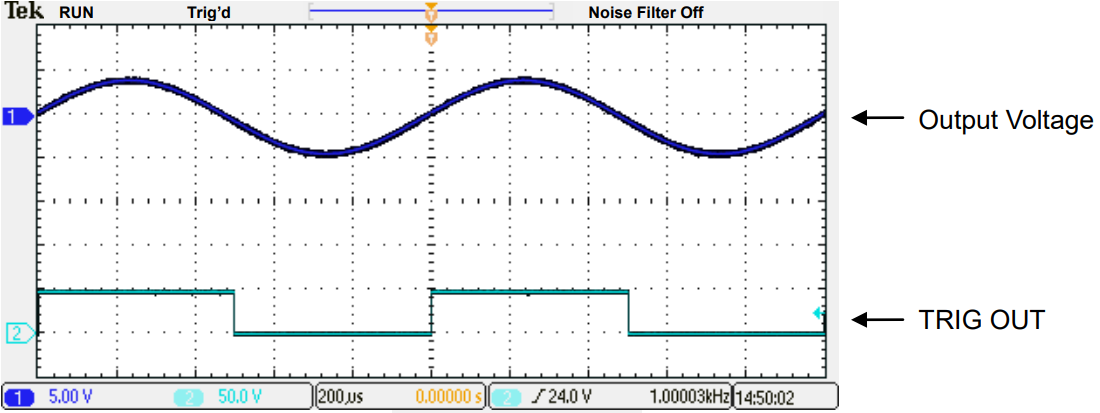

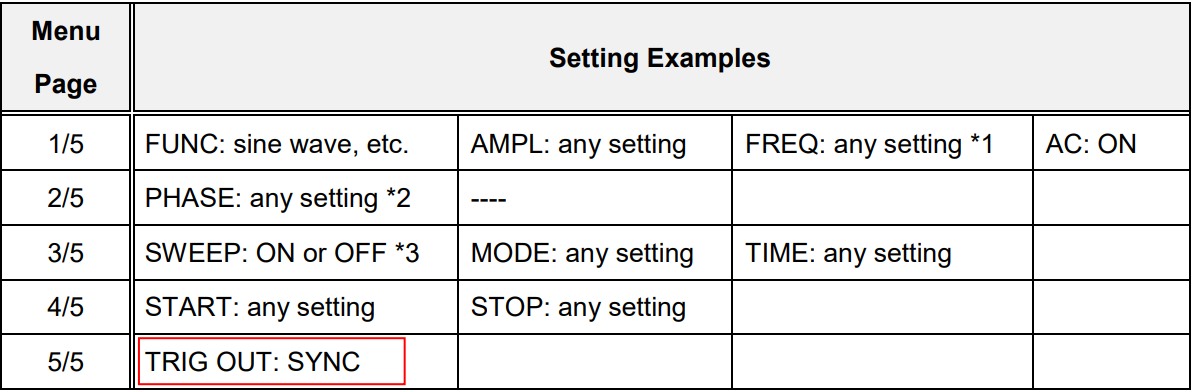

To transmit a synchronised trigger pulse for output, you can create a trigger signal output (TRIG OUT): through the sequence function or with the following settings. When you output a square wave signal, it is easier to configure the following settings. The settings are available in a single operation only, not in a synchronized operation.

1. Output ExamplePBZ outputs at 1 kHz.

2. Settings

Note: Set TRIG OUT to SYNC in the menu page 5/5. See the actual setting examples below:

*1: If SWEEP is set to OFF, set AC signal frequency in the FREQ setting.

*2: You can change the phase of output and trigger signal output (TRIG OUT) in the PHASE setting. *3: If TRIG OUT is set to SYNC, the square wave signal is outputted regardless of the SWEEP

setting.Products Mentioned In This Article:

- PBZ Series please see HERE

Current and Voltage Accuracy in Two Setting Methods

Current and Voltage Accuracy in Two Setting Methods

When setting the output current or voltage from DC power supply, a higher accuracy can be achieved by panel setting or remote PC setting instead of ammeter adjustment. Below explains the accuracy difference between these two methods taking PMX35-1A and PMX18-5A as an example.

CC Accuracy

1. Panel Setting/Remote PC Setting Accuracy

When setting CC with the SET button and knob, CC setting accuracy regards as how an actual CC value differs from a true value.

E.g.) For PMX35-1A and PMX18-5A, the setting accuracy value is: ± (0.3% of setting + 0.1% of rating).

When setting 300mA from the panel, the following error is included: PMX35-1A: ± (0.3 x 0.003 + 1 x 0.001) = ± 0.0019 (A)

PMX18-5A: ± (0.3 x 0.003 + 5 x 0.001) = ± 0.0059 (A)

It means that PMX18-5A may cause a larger error with this setting method. If you need to pass 1A, a higher accuracy can be achieved through PMX35-1A.

The same applies to the remote PC setting.

2. Ammeter Adjustment Accuracy

When setting CC (300mA) by adjusting an ammeter, the ammeter accuracy regards as how an actual CC value differs from a true value.

E.g.) For PMX35-1A and PMX18-5A, the ammeter accuracy value is: ± (1% of reading + 5 digits);

When setting 300mA by adjusting the ammeter, the following error is included: PMX35-1A: ± (0.3 x 0.01+ 0.005) = ± 0.008 (A)

PMX18-5A: ± (0.3 x 0.01+ 0.005) = ± 0.008 (A)

It means that PMX35-1A andPMX18-5A obtain the same error results with ammeter adjustment.Generally, the higher accuracy can be obtained by setting from panel or PC instead of adjusting

the ammeter.

Therefore, the current accuracy will be determined which method to be used.

Conclusion:

To improve the current accuracy;

1) Choose DC power supply whose rated current is close to your required value.

2) Set current from SET button or PC instead of ammeter adjustment.CV Accuracy

1. Panel Setting/Remote PC Setting Accuracy

When setting CV with the SET button and knob, CV setting accuracy regards as how an actual CV value differs from a true value.

E.g.) For PMX35-1A and PMX18-5A, the setting accuracy value is: ± (0.2% of setting + 0.1% of rating).

When setting 5V from the panel, the following error is included: PMX35-1A: ± (5 x 0.002 + 35 x 0.001) = ± 0.045 (V)

PMX18-5A: ± (5 x 0.002 + 18 x 0.001) = ± 0.028 (V)

It means that PMX35-1A may cause a larger error with this setting method.

If you need to apply 5V, a higher accuracy can be achieved through PMX18-5A. The same applies to the remote PC setting.

2. Voltmeter Adjustment Accuracy

When setting CV (5V) by adjusting a voltmeter, the voltmeter accuracy regards as how an actual CV value differs from a true value.

E.g.) For PMX35-1A and PMX18-5A, the voltmeter accuracy value is: ± (0.5% of reading + 2 digits);

When setting 5V by adjusting the voltmeter, the following error is included: PMX35-1A: ± (5 x 0.005 + 0.04) = ± 0.065 (V)

PMX18-5A: ± (5 x 0.005 + 0.04) = ± 0.065 (V)

It means that PMX35-1A andPMX18-5A obtain the same error results with voltmeter adjustment.Generally, the higher accuracy can be obtained by setting from panel or PC instead of adjusting

the voltmeter.

Therefore, the voltage accuracy will be determined which method to be used.

Conclusion:

To improve the voltage accuracy;

1) Choose DC power supply whose rated voltage is close to your required value.

2) Set voltage from SET button or PC instead of voltmeter adjustment.

Please be sure to verify each setting accuracy and meter accuracy before setting the output.Products Mentioned In This Article:

PMX Series please see HERE

How to Enable Positive/Negative Output from DC Power Supply

How to Enable Positive/Negative Output from DC Power Supply

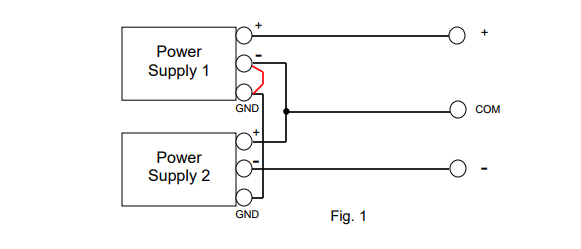

DC power supply can provide dual (positive and negative) output by following the method described in Section 1 below.

1. How to Produce Positive/Negative Output

1. Connect Power Supply 1 to Power Supply 2 in series.

2. Connect COM terminal to GND terminal.

3. Set each voltage from Power Supply 1 and 2.

2. Dual Tracking Function

Generally, DC power supply can feature ‘master-slave series operation’ function. With this function, Power Supply 1 acts as the controller for Power Supply 2.

E.g.) If Power Supply 1 outputs 5V voltage, Power Supply 2 automatically outputs also 5V voltage.

In dual (positive/negative) output power supply, this function is called as ‘dual tracking’ function that varies positive and negative voltages simultaneously.

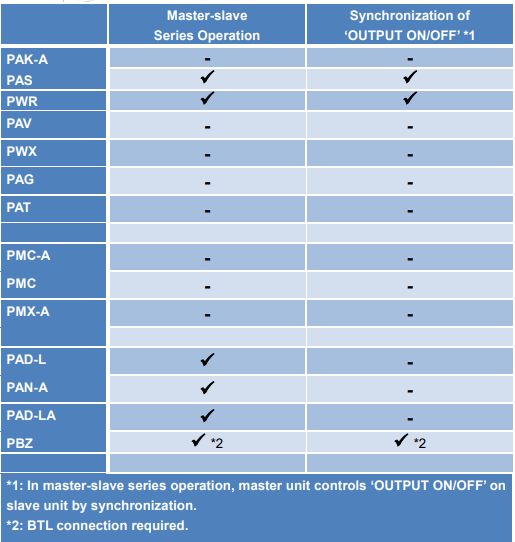

Some Kikusui’s DC power supplies support the master-slave series operation. For the function availability, please check the user’s manual of your model or see Table 1 in the next page.

In addition, if you output from two units of PCR-LE Series with 2P05-PCR-LE (optional board for single-phase three-wire output) in DC output mode, these units can act as dual tracking power supply.3. Dual Tracking Function Availability

Products Mentioned In This Article:

To view all Kikusui Power Supplies please see HERE

PLZ Series: How to Effectively Improve Safety during Load Testing of Non-isolated AC/DC Converter

PLZ Series: How to Effectively Improve Safety during Load Testing of Non-isolated AC/DC Converter

Considering minimising the potential shock hazard, the use of an isolation transformer or regulated power supply is critical during load testing of a non-isolated AC/DC converter (such as PFC). This white paper explains; what happens without an isolation transformer or regulated AC power supply and how important these are for safety reasons.

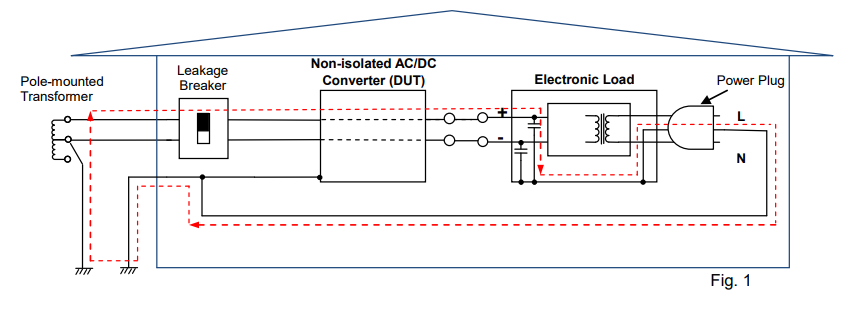

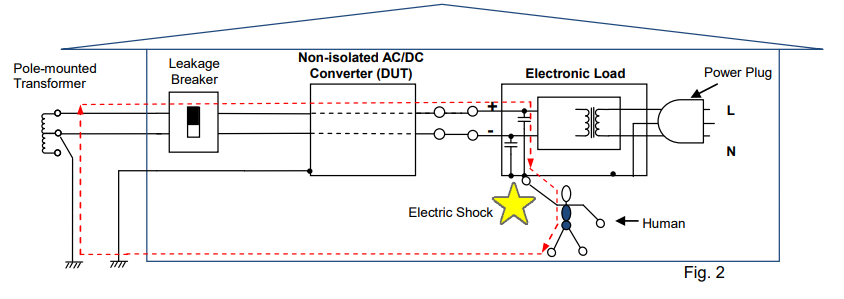

1. What happens if non-isolated AC/DC converter is directly connected to electronic load?

Figure 1: Since the DUT is non-isolated, the capacitor of electronic load, which placed at its DC input, passes the current though the enclosure of electronic load to the leakage breaker, thus shutting the breaker off.

Figure 2: Example that the GND terminal of electronic load (at the power plug) is not grounded; The leakage breaker will not shut itself off, but the voltage is applied to the enclosure of electronic load. Contacting such electronic load could expose an operator to an electric shock. Note: Our user’s manual advises users; ‘Be sure to earth ground the product to prevent electric shock’.

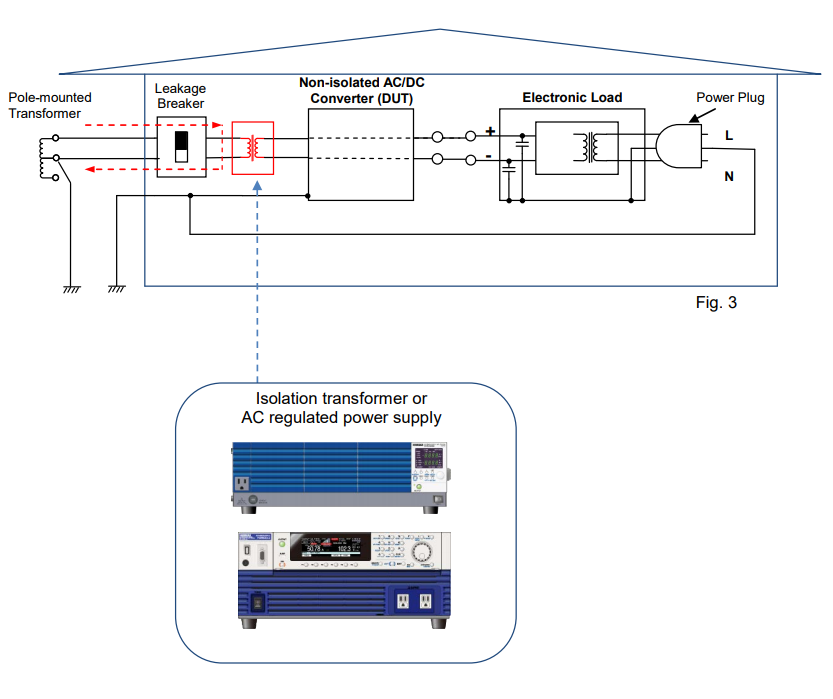

2. Preventive Action

To prevent the above interruption or shock hazard, add the isolation transformer or AC regulated power supply as shown in Figure 3, which can provide the electrical isolation between the utility power line and the primary and secondary terminals of DUT. This can greatly reduce the potential shock hazard for an operator.

3. Non-isolated DC/AC Converter Testing

The same situation may occur while performing a load testing on a non-isolated DC/AC converter (such as power conditioner) by using our AC electronic load PCZ1000A. In this case also, we highly recommend to use an isolation transformer or regulated power supply.Products Mentioned In This Article:

To view all PLZ Series please see HERE

PBZ Series: How to Change Pulse Width Using Sequence Function

PBZ Series: How to Change Pulse Width Using Sequence Function

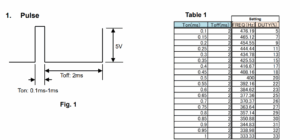

PBZ Series can change the square waveform frequency and duty cycle. Using the sequence function, you can also change the pulse width. The following sections explain how to change the pulse width according to Ton/Toff specified in figure 1 and table 1.

2. Create and Execute Sequence

1) Square wave frequency and duty cycle: See the ‘Setting’ column in Table 1. FREQ=1/ (Ton+Toff), DUTY=Ton/ (Ton+Toff)

2) Enter the above data into the sequence creation software (Wavy for PBZ).

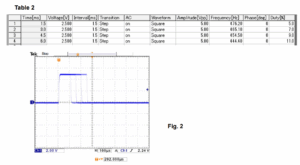

Table 2 shows the sequence example of the first four steps.

Note: Enter 0 in the Phase field. Interval should be shorter than one time period of the square waveform.Figure 2 shows the actual generated waveform (for Ton).

Products Mentioned In This Article:

PBZ Series please see HERE

How to Calculate Input Current for PCR-LE/MA Series

How to Calculate Input Current for PCR-LE/MA Series

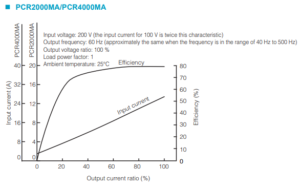

Before installing PCR-LE or MA Series, you may want to know how much current should be supplied from the distribution board. The best way is to calculate the current consumption (= input current) of your PCR-LE or MA Series. Here are the examples how to calculate the input current based on your output requirement (your output voltage and current):

Example 1: PCR3000LE

Condition: Input Voltage: Single-phase, 200 VAC

Output Voltage: 230 VAC rms, 10 A

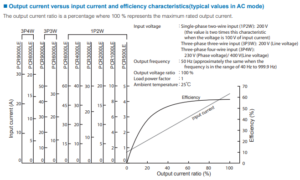

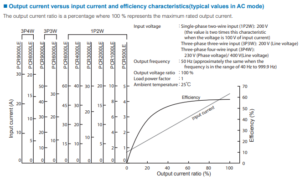

Method 1: Calculate based on Input Current Characteristics Graph

See Figure 1 from User’s Manual of PCR-LE Series – ‘Operating Characteristics’ (Page 93).

1. Calculate output current ratio

The output voltage is 200 V or higher: e.g. 230 V as above example. Calculate the percentage of output power to the rated power. This percentage is regarded as output current ratio:

Output power: 230 V x 10 A = 2,300 VA

Output current ratio: 2,300 VA / 3,000 VA = 0.766 = 76.6% 2. Find input current

You can find the input current through the red points on the above graph: e.g. If output current ratio is 76.6%, the input current is approx. 21 A.Method 2: Calculate based on Efficiency Characteristics Graph

See Figure 2 from User’s Manual of PCR-LE Series – ‘Operating Characteristics’ (Page 93).

1. Calculate output current ratio

The output voltage is 200 V or higher: e.g. 230 V as above example. Calculate the percentage of output power to the rated power. This percentage is regarded as output current ratio:

Output power: 230 V x 10 A = 2,300 VA

Output current ratio: 2,300 VA / 3,000 VA = 0.766 = 76.6%

2. Find efficiency

You can find the efficiency through the red points on the above graph: e.g. If output current ratio is 76.6%, the efficiency is approx. 57%.

3. Calculate input power (active power: W)Input power (active power): 2,300 VA / 0.57 = 4,035 W

4. Calculate apparent power (VA) and input currentThe power factor from the specification: 0.97

Input power (apparent power): 4,035 W / 0.97 = 4,159 VA Input current: 4,159 VA / 200 V = 20.79 A = approx. 21 A.Example 2: PCR1000MA

Condition: Input Voltage: Single-phase, 200 VAC

Output Voltage: 200 VAC rms, 3 A

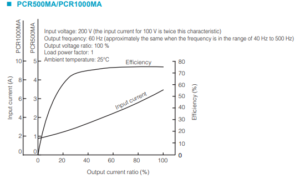

Method 1: Calculate based on Input Current Characteristics Graph

See Figure 3 from User’s Manual of PCR-MA Series – ‘Operating Characteristics’ (Page 63).

1. Calculate output current ratio

The output voltage is 200 V or higher: e.g. 200 V as above example. Calculate the percentage of output power to the rated power. This percentage is regarded as output current ratio:

Output power: 200 V x 3 A = 600 VA

Output current ratio: 600 VA / 1,000 VA = 0.6 = 60%2. Find input current

You can find the input current through the red points on the above graph: e.g. If output current ratio is 60%, the input current is approx. 4.4 A.Method 2: Calculate based on Efficiency Characteristics Graph

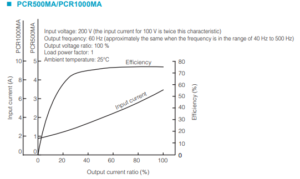

See Figure 4 from User’s Manual of PCR-MA Series – ‘Operating Characteristics’ (Page 63).

1. Calculate output current ratio

The output voltage is 200 V or higher: e.g. 200 V as above example. Calculate the percentage of output power to the rated power. This percentage is regarded as output current ratio:

Output power: 200 V x 3 A = 600 VA

Output current ratio: 600 VA / 1,000 VA = 0.6 = 60%

2. Find efficiency

You can find the efficiency through the red points on the above graph: e.g. If output current ratio is 60%, the efficiency is approx. 75%.

3. Calculate input power (active power: W)Input power (active power): 600 VA / 0.75 = 800 W

4. Calculate apparent power (VA) and input currentThe power factor from the specification: 0.9

Input power (apparent power): 800 W / 0.9 = 888 VA Input current: 888 VA / 200 V = 4.44 A = approx. 4.4 A.

Below is the Operating Characteristics Graph for PCR2000MA/4000MA as reference.

You can also calculate the input current for PCR2000MA/4000MA using the same method as above.

Products Mentioned In This Article:

Parallel Operation with Different Power Supply Models

Parallel Operation with Different Power Supply Models

The same model of Kikusui DC power supplies can be connected in parallel. By connecting the signal cables, one unit is set as the master unit and it can control the other units. This operation is called as ‘master-slave parallel operation’.

Master-slave parallel operation is not available when connecting the different power supply models. To increase the output capacity with the different models, the parallel operation described below is recommended. To perform this operation, you need to set the voltage or current for each unit. The simultaneous power on/off is available with the external control. Below is the operation example.

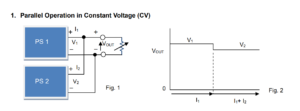

1. Parallel Operation in Constant Voltage (CV)

Firstly, connect two different power supplies ‘PS1’ and ‘PS2’ in parallel as shown in Fig. 1.

1. Set the output voltage for PS1 and PS2. The output voltage value for PS1 should be approx.

0.3V higher than that of PS2.

2. Set the rated CC value for PS1 and PS2.

3. Turn the output on for both units. The voltage is outputted from PS1.

4. Gradually decrease the load resistance to increase the current. Since the setting voltage for PS1 is higher, the current flows from PS1 only. When the current exceeds the rated CC value for PS1, the output voltage changes to the setting voltage for PS2. Then, the current also flows from PS2. In this example, the total current (I1+I2) is: rated CC value for PS1 + PS2 (see Fig. 2).

During this operation, the output voltage changes with the current; e.g.) It changes 0.3V in the above example. If the same voltage is set for PS1 and PS2 (the voltage difference is 0V), the current becomes unstable that alternately flows from PS1 or PS2. The required voltage difference depends on the power supply type in use. Please set the appropriate voltage difference to keep the parallel operation stable.

2. Parallel Operation in Constant Current (CC)

To operate in CC mode, it is not necessary to set a specific voltage difference on each power supply. The constant current can flow from both PS1 and PS2.Products Mentioned in this Application note:

Kikusui DC Power Supplies please see HERE

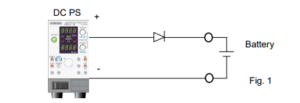

CC-CV Charging System without Series Diode

CC-CV Charging System without Series Diode

To charge batteries, it is recommended that you connect a diode in series at an output of DC power supply (See Figure 1). With a diode, constant current (CC) can be properly supplied; however constant voltage (CV) may be unstable if using remote sensing at battery terminals. Without a diode, a high current can flow between a battery and power supply when connecting or disconnecting a battery. Now, let me tell you other stable CC-CV charging methods with a switch instead of a diode.

1. Connect Sense Leads to Battery

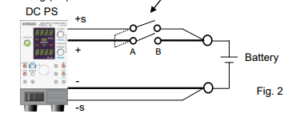

1.1 System Structure

Connect a double switch (SW1) as shown in Figure 2; one is for the output on/off switch and the other is for the sensing (+S) on/off switch.

1.2 How to Set Voltage and Turn SW1 On

Set the output voltage equal to the battery voltage and then turn SW1 on.

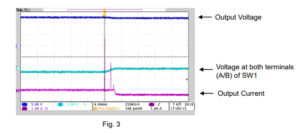

Figure 3 shows the output voltage, output current and voltage at both terminals (A/B) of SW1 when SW1 is turned on.

First, the output voltage increases by approx. 0.6 V because the sensing switch (+S) is open. At the time when SW1 is turned on, the small overcurrent is generated because an output current starts flowing or a switch chattering occurs. After SW1 is turned on, the output voltage becomes nearly equal to the battery voltage; the current will stop flowing.

Finally, apply CV voltage to start CC-CV charging.

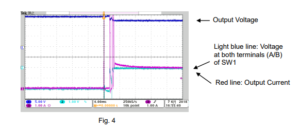

Note: If you initially set CV voltage and then turn SW1 on, an excess overcurrent flows as shown in Figure 4.

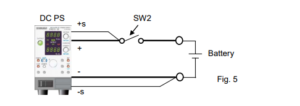

2. Connect Sense Leads to Switch

Figure 5 shows how to connect sense leads to switch (SW2). Set the output voltage equal to the battery voltage and turn SW2 on; an overcurrent will not flow.

Then, apply CV voltage to start CC-CV charging.

3. Others

Above systems can serve as your reference. Before configuring your own system, please be sure what type of switch you need.How do I pick the right spectrum analyser for my application?

Introduction

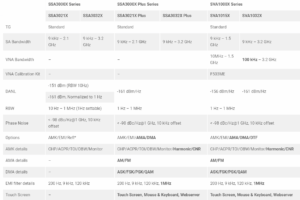

The SIGLENT SSA3000X, SSA3000X Plus and SVA1000X products are based on a similar swept superheterodyne spectrum analyser platform and have very similar starting prices. There are quite a few similarities, but also a few differences that could affect the end results for particular applications.

The table below compares the major specifications and the comparable options as they pertain to specific applications like VSWR.

*Compatible with many commercially available return loss bridges/directional couplers

Additional SVA Features and Options

Still having trouble choosing?

Here are some additional features and options that are exclusive to the SSA PLUS and SVA platforms that may help:

Free Features:

- Touch screen control with shortcut widget

- Mouse/Keyboard support

- Easy web browser web control

- Power-On-Line – Instrument will automatically restart when power is restored to the mains power connection (power cord) when this feature is enabled.

Additional Options:

- AM/FM modulation analysis (SVA1000X-AMA. SSA3000XP-AMA) enables visualization of data encoded using AM/FM

- Digital modulation analysis (SVA1000X-DMA. SSA3000XP-DMA) enables visualization of data encoded using FSK/ASK

- Advanced measurement kit (SVA1000X-AMK, SSA3000XP-AMK) feature Harmonic and CNR measurements in addition to CHP/ACPR/TOI/OBW/Monitor.

- Mechanical calibration kit for VNA (F503ME)

If you have additional questions, you can always contact our applications team (info@siglent.com) and we would be happy to answer any additional questions you may have.

Products Mentioned In This Article: