Your cart is currently empty!

Author: James

How to Select a Right DC Power Supply Part 2: Key Considerations

Welcome back to Part 2 of this series! Part 1 is all about the functions and characteristics of DC power supplies. In Part 2 here, we will take a look at the considerations when selecting a right power supply.

1. Key Considerations

There are too many considerations when selecting a DC power supply. This makes it hard to select a right power supply without any understanding, which is the topic we are going to explore here.

In Part 2, we will look at two main considerations: basic considerations and specific requirements for a DC power supply. First, start with the basic considerations which are most important factors in the power supply selection. The next is the specific requirements, which are mainly related to:

1) performance requirements 2) function requirements 3) system expansion requirements 4) requirements for flexibility in your system 5) safety requirements and 6) maintenance requirements.

In choosing a power supply, it is very important to be clear about what you want to achieve. So, Part 2 guides you to determine exactly what you are looking for in a DC power supply. Each of the sections below is considered in more details with particular examples or technical advice. Furthermore, we will not cover here in details, but you may need to think about your priorities, point of compromise, how to use or combination with other components in your system to find a best DC power supply.

1-1. Basic Considerations

The following are very important considerations that you should take into account.

1) Voltage and Current

Determine how much voltage and current that you need.

2) Wattage

Calculate the maximum power wattage to be achieved according to the voltage and current. Consider using a multiple-range power supply depending on your application.

3) Load Type and Current

Check your load type, load current (e.g. pulse current) and load current waveforms.

One last recommendation: You can use the five Ws and one H approach to find out what you need from a DC power supply: who, what, when, where, why and how.1-2. Specific Requirements

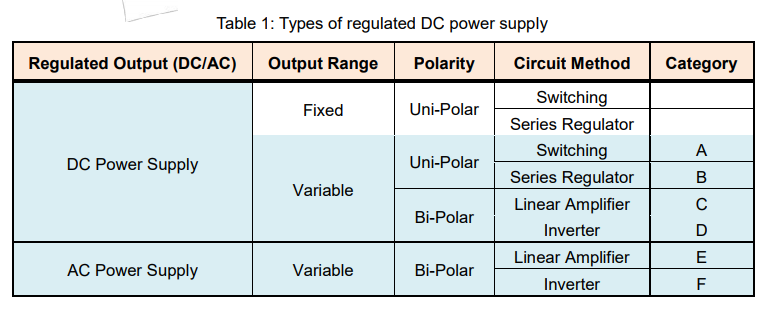

This section uses the table below again:

1-2-1. Performance Requirements

1) Low Ripple and Noise

To achieve a low ripple and noise, select the B-type or C-type power supplies. The B-type power supplies, series regulator DC power supplies, have a low ripple and noise. The C-type power supplies, linear DC power supplies, can offer high speed and low noise. Read data sheets or specifications for the details.

2) Pulse-waveform

If your project requires sharp pulses such as sharp rising and falling in 5 µs, choose the linear

power supplies (C-type). If your project requires 30 µs, you can also use the inverter DC or AC

power supplies (D and F-type) or linear AC power supplies (E-type). The E-type and F-type

power supplies are high-voltage power supplies, but if you need higher voltage and high-speed pulses, add a pulse generator in your system. With a pulse generator, the switching DC power supply (A-type) or series regulator DC power supply (B-type) can be also used.

3) Absorb reverse current from load

The bipolar linear DC or AC power supplies (C or E-type) can absorb a current source such as a motor reverse current. Some bipolar inverter AC power supplies can return the absorbed current to a power line. Other than them, place a resistor or electronic load in parallel with your power supply to absorb it.

4) Fine Voltage Adjustment

A voltage setting resolution is stated in data sheets or specifications; e.g. 0.012 % of full-scale (max. voltage). The more voltage the power supply has, the more rough adjustment is achieved in constant voltage mode. The voltage setting resolution may differ depending on the setting method: set by panel or communication command.

5) Inrush Current

You need to consider the voltage rise time before selecting a power supply.

Pulsed inrush current is drawn by DUT when first turned on. The voltage rise time for typical DC power supplies is 50 ms or more, so the inrush current cannot be easily obtained even if your DUT has capacitive properties. To correctly measure the inrush current, the input voltage should have the rapid rise time. Placing a switch at the power supply output is effective to control the voltage rise time within 1 µs or less.

Capacitive current (Ic) = C x dV/dt; Large capacitors may cause a large current spike.

The switching DC power supply (A-type) has a large capacitor at its output side to be able to flow more inrush currents. There are power supplies with specific inrush current capability designed for use of large motors.

6) Power Efficiency

The power loss is the power difference between electricity input and output as a result of an energy transfer from AC voltage to DC voltage. The power conversion efficiency is usually 70 – 90 % and the high efficient power supply is the switching type power supply such as A, D or F-type on Table 1.

The most efficient way is to use the rated power from your power supply. Do not select a power supply with much higher power ratings than you actually need.

7) Low Current Consumption

To reduce a current consumption, use a high efficient power supply (read 6. Power Efficiency) or get a higher input voltage as much as possible.

The power supplies with a power factor correction circuit use less input current. A high power factor (close to 1) indicates good use of the incoming supply.

8) Takt Time

Takt time is the rate at which a product needs to be completed and is used to describe how fast or slow production takes place based on customer demand. Manufacturers are expected to reduce the takt time while increasing the productivity per unit time.

The DC power supplies are typically used in production test systems to apply various test voltages on a DUT. Their high speed response is important to reduce the takt time. Also, the signal lags between transmitting an output-on command and actual voltage rising needs to be minimized.

C, D, E or F type power supplies, the high speed power supplies, can quickly switch the output voltage, but the time taken for the signal lag was not much different between all types of power supplies. You can find a multi-output power supply with high set speed, but consult with the vendor or maker to confirm the exact information before making any decisions.

For the analogue control power supplies, the takt time can be reduced depending on how they are used.

9) Pulse Current

In pulse current, a duty ratio is the ratio of the on-time to total time of the current waveform, where total time is an on-and-off cycle (pulse cycle). If your load accepts the pulse current to flow with duty ratio 50 % and pulse cycle 5 ms or more, use any DC power supplies. If a pulse cycle is 1 ms or less, use either of B, C, E or F type power supply.1-2-2. Function Requirements

1) Various Applications

When testing your DUT with different voltages or currents within the same operating area, the multiple-range DC power supplies are recommended. If you use a high-power power supply for small-power applications, its efficiency is decreased.

2) Bipolar Output

Using two units of DC power supplies can make a bipolar output. Place a switch to control the output on/off synchronization, if needed.

With a master-slave parallel operation function, the entire system can be controlled by the master unit. This function is similar to the dual tracking function (check Part 1 – Figure 9) of the multi-output power supplies. The multi-output power supplies often feature the output on/off synchronization function.

3) Remotely control power supplies

The modern DC power supplies often feature a LAN port. Multiple power supplies can be controlled with a LAN hub connected. Output on/off synchronization may be also available via LAN interface. The LAN interface will increase in popularity for DC power supplies.

4) Use as DC and AC power supply

C, D, E and F type power supplies, bipolar power supplies, can provide both DC and AC outputs. Especially, E and F type power supplies, bipolar AC power supplies, are more appropriate to provide high voltage output.

5) Voltage Waveform Generation

C, D, E and F type power supplies tend to have the voltage waveform generation function. These are the high speed power supplies and the voltage rising and falling time is from 3 µs to 30 µs, which can generate desired waveforms.

Some power supplies allow users to customize waveforms with their internal function generator. You can use this sequence feature to customize certain times or levels of waveforms and save the sequences into the power supply itself.1-2-3. System Expansion Requirements

1) Increase power supply capacity

There is the master-slave parallel function which is performed by designating one master unit and connecting it to one or more of the same models being the slave units. The entire system can be controlled by operating the master unit. Output current and power can be greatly amplified under this operation.

To double the output voltage, connect two units in series. The maximum number of series connection units differs by power supply models.

2) Increase control units

The number of control units can be adjusted via communication network.1-2-4. Requirements for Flexibility in Your System

1) Low Noise

DC power supplies were originally designed for use in laboratories and factories, so it is quite normal that their cooling fans get larger and louder. In some power supplies, the cooling fan can make less speed and noise during low-power outputs.

2) AC Input

Depending on the model, but mostly in E and F type power supplies, the input voltage range is specified from 85 VAC considering the input voltage drop. See the data sheets or specifications to check the input voltage range.

3) Under 15 A Circuit Breaker

Keep the power supply operation within the 15 A circuit breaker rating. Check the output power rating of a power supply before use.

4) Harmonic Current Reduction

A power factor correction circuit is necessary in high-power power supplies to improve the power factor. Please be noted that some power-saving power supplies do not have it.

5) Inrush Current Protection

Inrush current protection circuit is installed in almost all power supplies to prevent it. However, small-sized power supplies installed a commercial transformer may not have it.

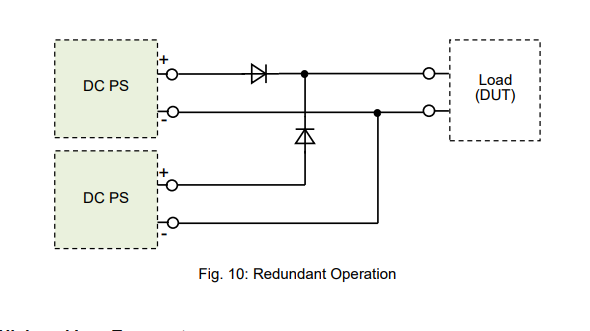

6) Backup or Redundant Power Supply

It is the best way to prepare a back-up power supply to ensure the operation for your critical application during power failure or breakdown, or you can have redundant power supplies.

A redundant power supply is when a DUT operates using two power supplies in parallel with diodes as below. Each of the power supplies has the capacity to run this DUT on its own, which allows it to operate even if one goes down. During normal operation, each of the power supplies provides half of the power that is needed.

7) High and Low Temperature

The typical safe temperature range for DC power supplies is 0 – 40 C°, but the range can be extended to 50 C° depending on the models.

8) Mount in 19-inch rack

Check the availability of 19-inch rack mount accessories.1-2-5. Safety Requirements

1) Safety

Most DC power supplies comply with IEC61010.1-2-6. Maintenance Requirements

1) Warranty Period

The warranty period has been recently extended. Ask your vendor or maker.

2) Lifetime and Mean Time Between Failure (MTBF)

DC power supplies can last a very long time by making a repair. There might be no specific expected lifetime but the mean time between failure (MTBF) is defined.Products Mentioned In This Article:

- DC Power Supplies please see HERE

Voltage Interruption Waveforms Provided by PCR-LE Series

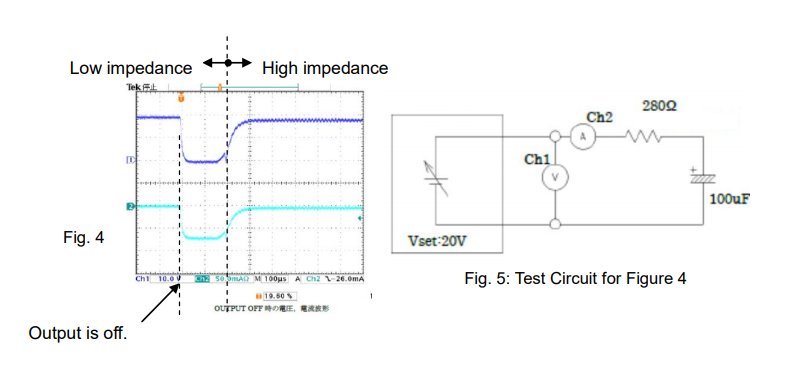

In an AC circuit, power supply interruption can be mainly divided into two types: it occurs with low impedance or with high impedance.

The power supply interruption with low impedance is a short-circuit interruption. A short circuit is an unintended path to flow a current with typically very low impedance. Whereas, the power supply interruption with high impedance is an open-circuit interruption. An open circuit is a circuit where a path has been interrupted or a path has been opened by any contact failure. Both interruptions are instantaneous interruptions that end in a short period of time.

As a reference, let’s see the measurement waveforms below showing short-circuit/open-circuit voltages. * This white paper is supplemental to the main paper ‘How Does Surge Suppression Work in PCR-LE/LE2 Series?’. For the details of the Surge Suppression function, please read the main paper.

Equipment Conditions:

Power Supply: PCR500LE, set voltage: 100 Vdc, load current (using resistance load): 2.82 A Application Software: SD11-PCR-LE

1. Short-Circuit Voltage Waveforms (Low Impedance)

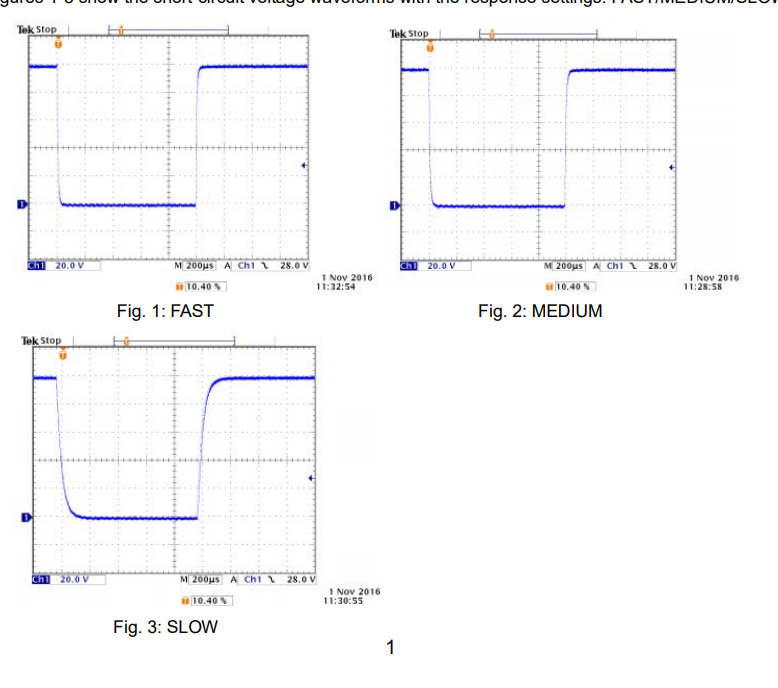

Power supply interruption method: The output voltage was set to 0 V for 1 microsecond. When the output was set to 0 V, PCR-LE provided the low impedance output.

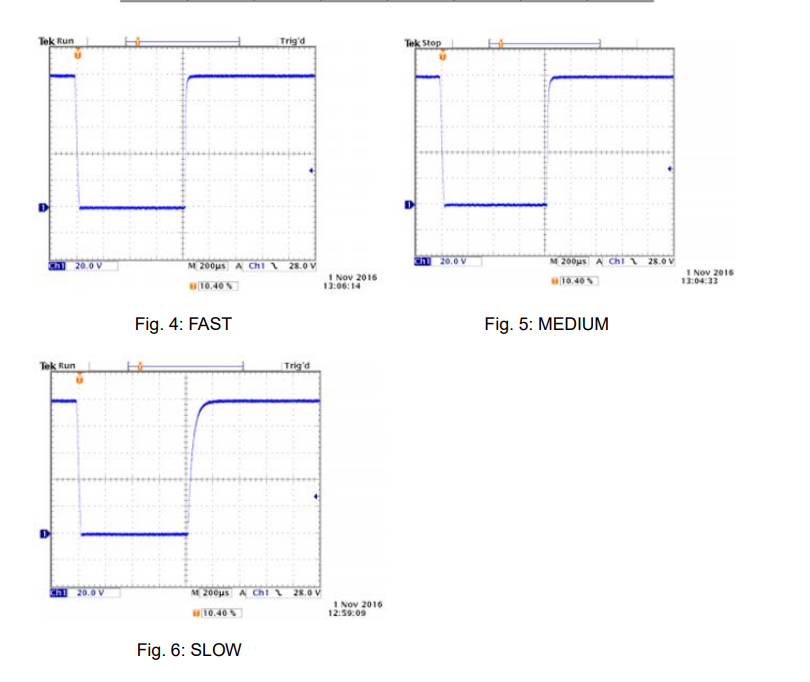

Figures 1-3 show the short-circuit voltage waveforms with the response settings: FAST/MEDIUM/SLOW.

2. Open-Circuit Voltage Waveforms (High Impedance)

Power supply interruption method: The output was turned off for 1 microsecond. Specific setting: Surge Suppression was set to off.

When the output was turned off, PCR-LE provided the high impedance output. See the high impedance value in Table 1.

Figures 4-6 show the open-circuit voltage waveforms with the three response settings.

Products Mentioned In This Article:

- PCR-LE Series please see HERE

How to Reduce Power Supply Noise

In a test system, AC power supply is one of the significant components that can create test sequences for output and supply source to DUT. However, the power supply may cause a noise issue during test. There is some noise interference such as conducted noise and magnetic field that may enter into the test system.

This article focuses on a noise terminal voltage at an input and output terminal which is regarded as conducted noise and introduces how to reduce it. The procedures below are also effective for DC power supplies.

*In the following examples, the measured noise is below 150 kHz.1. Type of Power Supply Noise

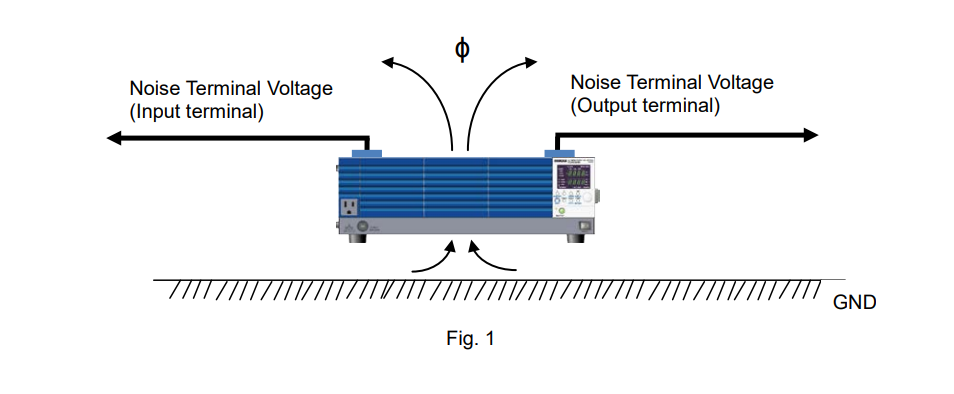

As shown in Figure 1, the power supply noise is mainly classified into the noise terminal voltage (at the input and output terminal) and emission noise. The emission noise is emitted as the magnetic field and measured as the noise voltage.

2. Noise Terminal Voltage at Input Terminal

2-1 Measurement Circuit Configuration

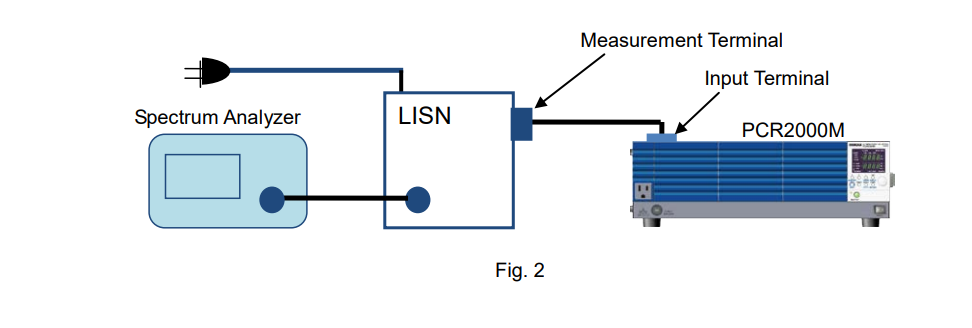

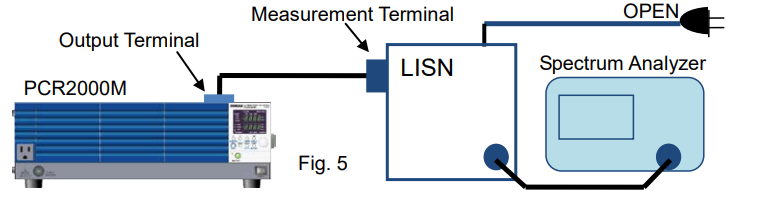

Figure 2 shows that the input terminal of PCR2000M is connected to the Line Impedance Stabilization Network (LISN) to measure the noise terminal voltage.

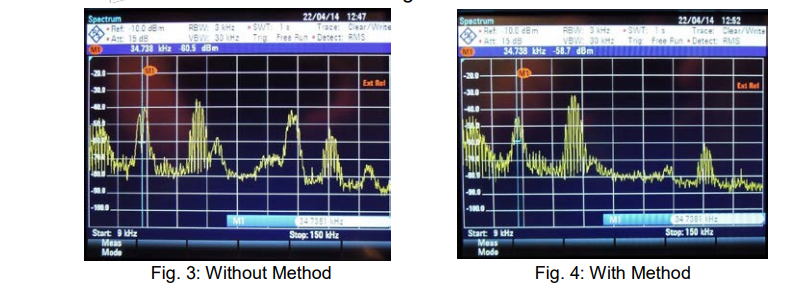

2-2 Method and Result

Connect the input N terminal to the GND terminal (See Figure 4 for the result). If the system has a leakage current breaker, it may shut down. To avoid this, add a capacitor between the N terminal and GND terminal to flow the leakage current.

3. Noise Terminal Voltage at Output Terminal

3-1 Measurement Circuit Configuration

Figure 5 shows that the output terminal of PCR2000M is connected to the LISN to measure the noise terminal voltage.

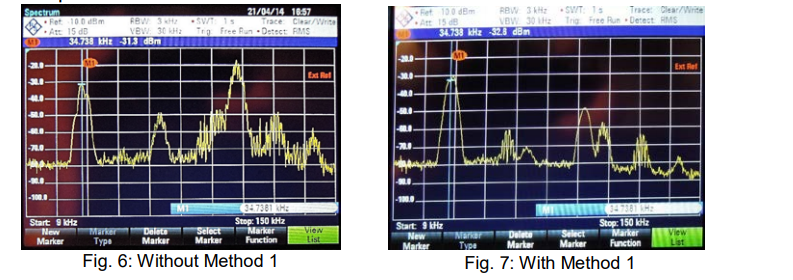

3-2 Method 1 and Result

Method 1: Connect the output N terminal to the GND terminal. If you cannot directly connect them, add a capacitor between the N terminal and the GND terminal.

3-3 Method 2 and Result

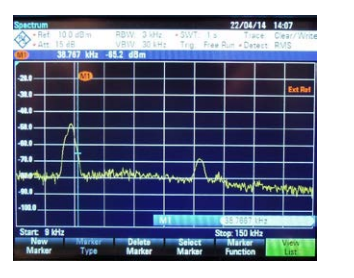

Method 2:

1) Add an inductance* to the output L terminal.

2) Connect the output N terminal to the GND terminal. (*Wind 6 turns on a toroidal core.)

Products Mentioned In This Article:

- Kikusui AC Power Supplies please see HERE

DC Electronic Load – Part 6: Application and Example (2)

Continuing from the previous white paper, here are three more effective applications and examples of electronic loads.

6-1. Applying the Load to a Motor

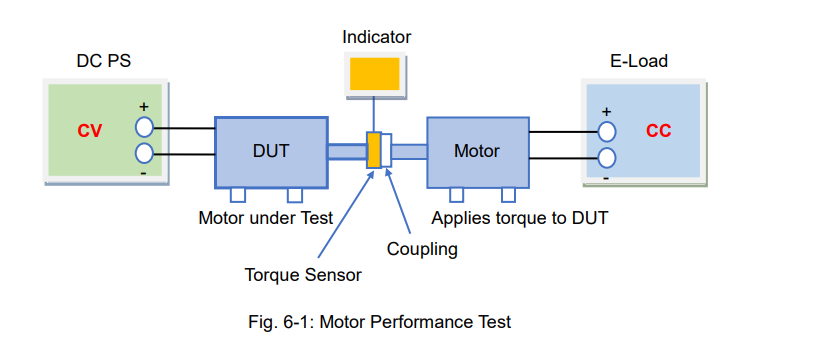

Figure 6-1 shows a block diagram illustrating an example of the DC motor test system.

In this system, the test motor (DUT) is driven by the DC power supply. The coupling is connected to the DUT and another motor in order to apply torque to the DUT. The torque sensor is placed between the DUT and coupling in order to measure the torque and rotation speed. The electronic load is connected to the motor to draw the current.

If the motor’s current in increased by the load while operating the DUT, the DUT’s motor torque will also increase. So, the electronic load adjusts the torque applied to the motor in order to obtain the T-N characteristics: the relationship between the rotation speed and torque.

6-2. Absorbing the Motor Regenerative Current

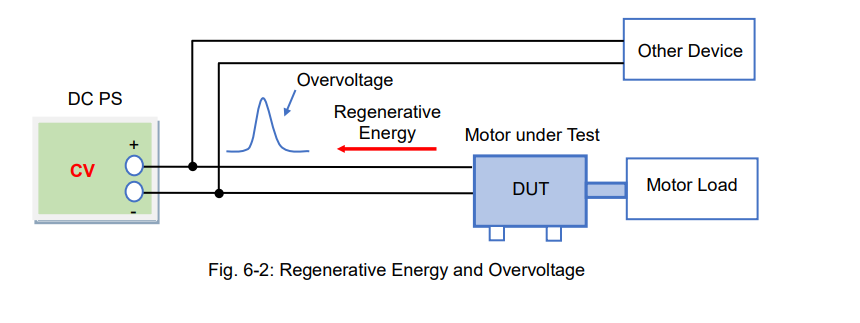

Reverse voltage is generated and returned to a power source by reversing the direction of the motor. Batteries can absorb this regenerative energy, but typical DC power supplies*1 cannot. So, the overvoltage may flow to the output terminal of a DC power supply. This activates an overvoltage protection in the DC power supply, but this overvoltage may reach other devices on the same test system.

*1: A bipolar DC power supply can absorb regenerative power like a battery.

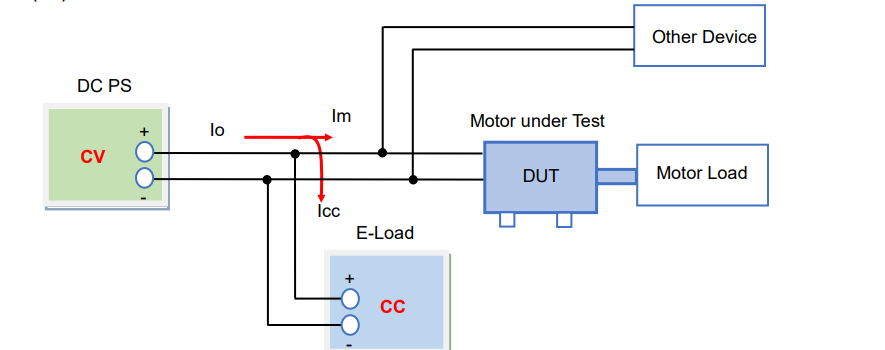

To prevent this, set the electronic load to the constant voltage (CV) mode as described in Part 3, Sec.3-1 or, set it to the constant current (CC) mode as described in figure 6-3 blow. In figure 6-3, the DC power supply and electronic load are connected in parallel. The electronic load operates in CC mode and this CC current should be set to exceed the DUT’s regenerative current. When the current (Io) flows from the DC power supply, the electronic load draws ‘Io’ and converts in into ‘Icc’. And when the test motor (DUT) is driven, the motor current (Im) is fed into the DUT. Therefore, Io = Icc + Im.

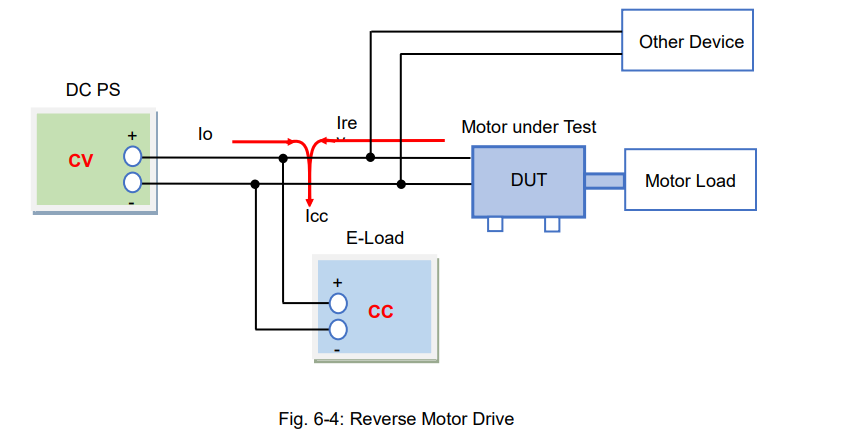

Figure 6-4 shows how the DUT regenerates the current to the DC power supply. During power regeneration the motor regenerative current’s (Irev) direction reverses and flows into the electronic load. However, the electronic load works to keep its current (Icc) constant. Therefore, Icc = Io + Irev. When ‘Irev’ increases, the DC power supply current (Io) decreases, and vice versa (‘Irev’ decreases = ‘Io’ increases).

This system is more effective for preventing overvoltage than clipping the voltage with the CV setting, but it consumes more power.

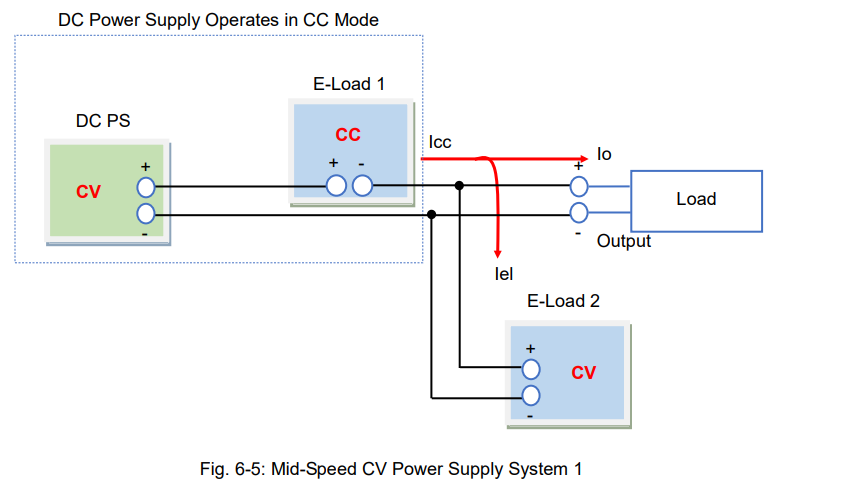

6-3. Building a Mid-Speed CV Power Supply System

The voltage rising and falling time of typical DC power supplies exceeds 10 milliseconds (ms), but high-speed DC power supplies limit it to 3 micro seconds (µs).

Instead of buying a high-speed power supply model, you can build a mid-speed CV power supply system (Tr/Tf: 100 μs to a few ms) by combining your own DC power supply with an electronic load. Let’s look at the two examples below.

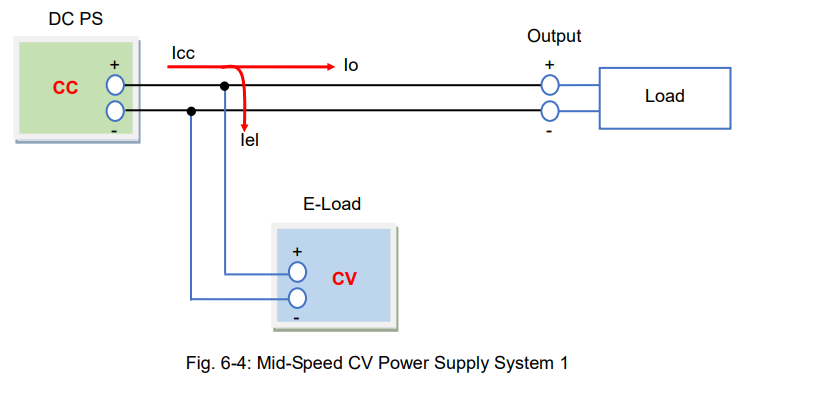

1. Mid-Speed CV Power Supply System (1)

In figure 6-4, the DC power supply and electronic load are connected in parallel. For the DC power supply, set the CC value to more than the maximum current that the load uses. The electronic load maintains a CV set voltage, and you can adjust it using your PC.

Under the no-load condition, the output current from the DC power supply (Icc) all flows into the electronic load.

With the load-on condition activated, the load current (Io) is fed into the load by reducing the flow of the E-load current (Iel). Therefore, Icc = Io + Iel.

If you use a series regulator power supply, the response time could take a few milliseconds. For typical switching power supplies, the response time takes more than 10 milliseconds. However, this depends on how quickly the electronic load activates the CV mode, so you need to verify the actual time.

Note: this system can maintain speed even with capacitive loads because the electronic load can sink (absorb) current from the load. The regenerative current of the motor mentioned above can be absorbed.

2. Mid-Speed CV Power Supply System (2)

The system, as shown in figure 6-5, is faster than the system shown in figure 6-4, achieving about 100 microseconds.

In figure 6-5, the DC power supply and electronic load are connected in series to allow the DC power supply to operate in CC mode. The operation of this DC power supply is the same as the one shown in figure 6-4. For electronic load 1, set the CC value above the maximum current that the load uses. Since electronic load 2 operates in CV mode, it maintains a CV set voltage and you can adjust it with your PC.

Under the no-load condition, the output current from load 1 (Icc) all flows into load 2.

With the load-on condition, the load current (Io) is fed into the load by reducing the flow of the electronic load current (Iel). Therefore, Icc = Io + Iel.

The reason this system is faster is because the CC mode operation of load 1 is exceptionally fast (approx. 50 microseconds faster).

DC Power Supply Operates in CC Mode

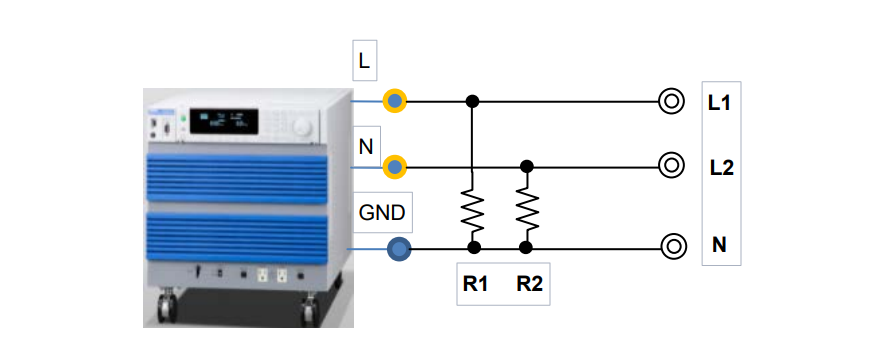

Single-phase Three-wire Output from One AC Power Supply

A single-phase three-wire output can be achieved usually by connecting two AC power supplies. However, if you need to output from one AC power supply and the required current through DUT is small, you can output it by configuring the following circuit.

1. Single-phase Three-wire System

In the figure below, R1=R2. Appropriate resistance for power supply should be applied on R1 and R2. With smaller resistance, the output can be nearly equivalent to the actual single-phase three-wire. The L1 to N voltage and L2 to N voltage are half the L1 to L2 voltage.

Note:

With the above circuit configuration, the L1 to N and L2 to N at AC100V are not available to consume the power.

2. Other Method

Transformer can be used to provide the single-phase three-wire output.Products Mentioned In This Article:

- Kikusui AC Power Supplies please see HERE

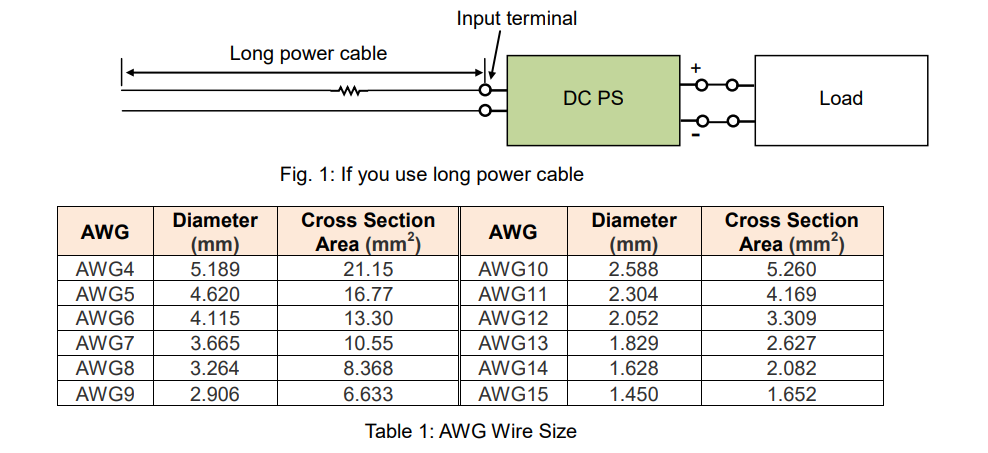

What It Takes to Keep Regulated DC Power Supply Stable Part 1: Connecting Cable

A regulated DC power supply (referred as DC power supply) is an electrical device to convert AC into a constant DC. Its function is to maintain a constant output voltage, however, unfortunately even if you use an intelligent DC power supply, improper wiring can mess up a whole system operation or performance.

In this white paper, we explain the best practices for connecting a power cable and load cable to the DC power supply (assuming that the DC power supply operates in constant voltage mode). It can help you learn more about typical wiring problems in an electrical system and how to avoid them.

1. If you use long power cable

A power cable is a fundamental component that transmits electric power to devices in any electrical system. Basically, as the more power is produced by a DC power supply, the more current flows through a power cable.

Also, a power cable resistance is proportional to its length. That is, an AC-line input voltage can drop over a long power cable. As the more power is produced by a DC power supply, the more AC-line input voltage drops.

If an AC-line input voltage falls to a minimum rated input voltage of a DC power supply, an output voltage can decrease or fluctuate. Even worse, an input voltage drop protection may activate to turn the output off.

Before you have such issues, check whether an AC-line input voltage meets a rated input voltage first and then take the following preventive actions, if needed:

1) Use a power cable as short as possible. If a cable length becomes half, an input voltage drop becomes half, or

2) Use a power cable as thick as possible. If a cross section area of a power cable is doubled, an input voltage drop becomes half, or

3) Check for a loose power cable connection and tighten it when necessary.

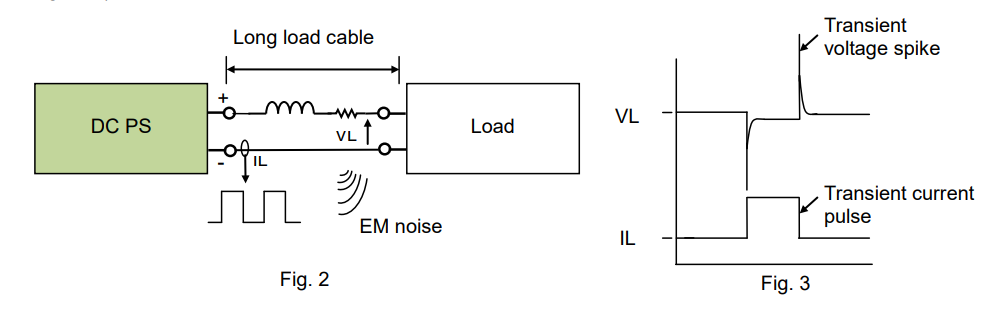

2. If you use long load cable

With a long load cable, a load current can increase and then a load voltage drops. To compensate for the voltage drops, some DC power supplies feature a remote sensing function. This section explains the different effects between using and not using the remote sensing function.

2-1 Using remote sensing function

The wire inductance is proportional to the length of the load cable. When the load current (‘IL’) is pulsating and rapidly fluctuates, the load voltage (‘VL’) also oscillates in response to IL (See Figure 3).

With the long load cable, the entire system may not work as expected because;

The transient load voltages may cause the malfunction to the load.

The transient cable current may become an EM noise source.

To avoid them;

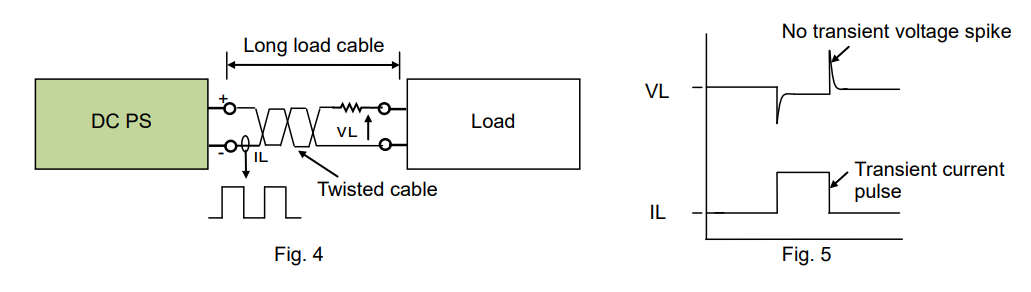

1. Twist the positive and negative load cables together as shown in Figure 4 or 2. Place them as close as possible.The twisted pair cable can reduce the effect of the EM noise and then reduce the transient voltage change (See Figure 5).

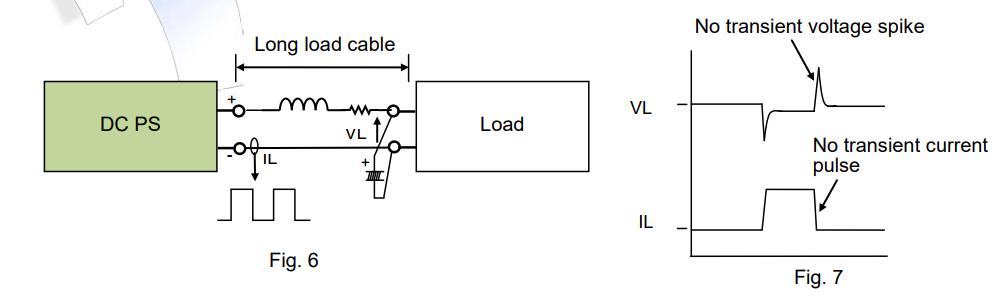

With or without above actions taken, if the transient voltages still persist, place an electrolytic capacitor (‘C’) as shown in Figure 6 below. The capacitor can prevent the transient current from superimposed on IL. For faster transient currents, place a ceramic capacitor in parallel with C. As shown in Figure 7 below, IL has no rapid change, and consequently VL is regulated.

*Note: All figures given in this section illustrate the equivalent circuits of the system. The wiring diagrams are simplified that the resistance and inductance components are illustrated on the positive terminals only.

2-2 Not using remote sensing function

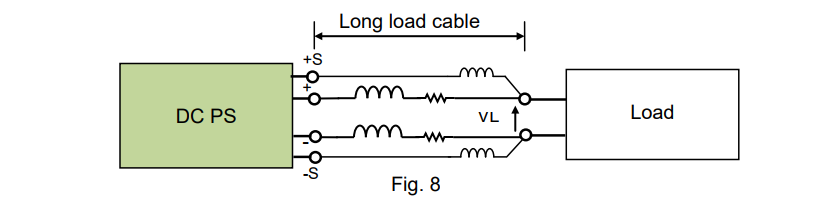

See Figure 8 for the equivalent circuit of the remote sensing connection. All cables consist of resistance and inductance components and the voltage will drop across these components. The remote sensing function can compensate for this voltage drop and keep the load voltage (‘VL’) stable within a set voltage. However, sometimes it does not work that the cable inductance may induce the oscillation.

To avoid the oscillation;

1) Twist the positive and negative load cables together (or place them as close as possible) to reduce the cable inductance.

2) Twist the positive and negative sensing cables together or use a shielded twisted pair cable to reduce the cable noise and inductance.

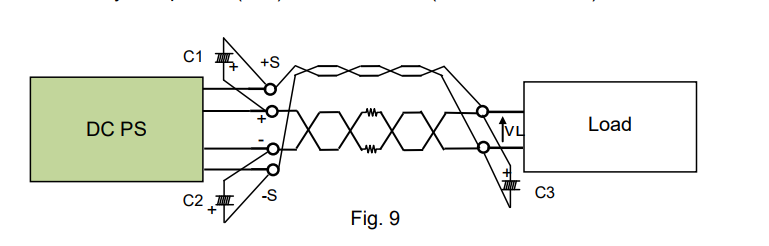

For further improvement;

3) Place a capacitor ‘C1’ and ‘C2’ across each positive terminals and negative terminals as shown in Figure 9. It allows the DC power supply to make a slow response to the load voltage fluctuations at a high-frequency, but the load voltage may become unstable. To fix it, place an electrolytic capacitor (‘C3’) on the load line (Read Section 2-1).

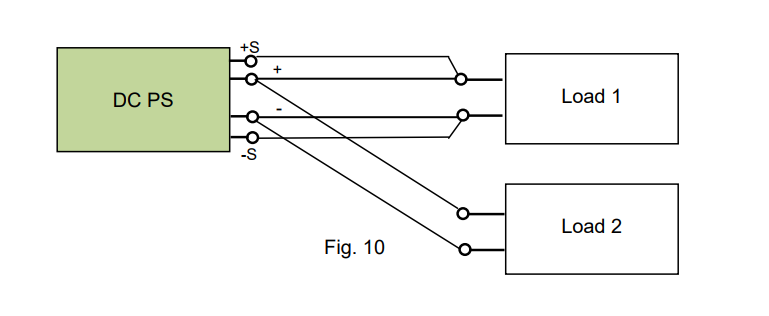

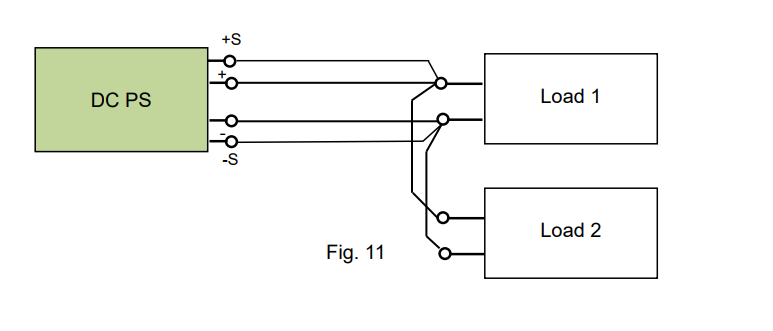

Figure 10 and 11 show the multiple load connection examples. As you can see, the sensing connection should be made to only one unit of load.

In Figure 10, assuming that the wire resistance and cable length are the same in Load 1 and Load 2, then the similar load voltage can be achieved for both loads. Also note that, if Load 2 is in a light-load state, the voltage drop can be offset by the sensing function for Load 1, but this compensation voltage may be directly added to Load 2.

In Figure 11, the load cable connected between Load 1 and Load 2 are thicker and shorter to minimize the wire resistance. This is especially helpful in obtaining a stable voltage when Load 2 is in a light-load state.

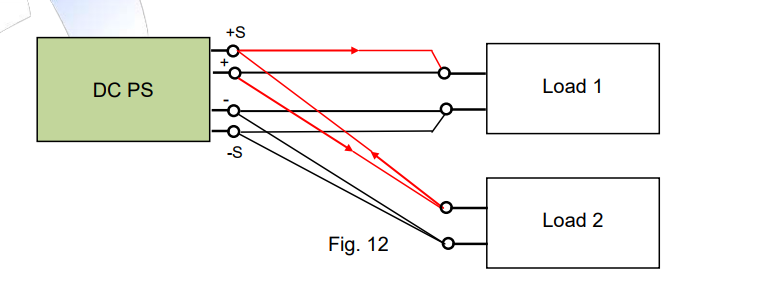

Figure 12 below shows the incorrect example that the sensing connection is made to each load. In such connection, the following may happen;

First, the load current through the load cable depends on each load state, and the voltage across each load depends on the load current. If using loads with different capacity, the load voltage balance cannot be maintained and the potential difference may be applied between the loads. With the potential difference, the current may flow from the high to low voltage via the sensing wiring. For example, see the red arrows in Figure 12 (positive side example only). If this current is high enough, the sensing cable may burn out.

Caution: Always perform a single sensing connection on multiple loads for safety.

Part 1 has so far focused on the wiring effects on the DC power supply.

Next, Part 2 will continue how the DC power supply depends on load conditions. Please also read Part 2 to gain further understanding or insights.Products Mentioned In This Article:

Kikusui DC Power Supplies please see HERE

Switching Function Improvement in PLZ5W Series

PLZ5W Series features a switching current function to repetitively fluctuate between two current levels, and this function has been improved as compared with the previous model of PLZ4W Series for the following characteristics:

1) Switching speed

2) Switching waveform quality

* In PLZ4W Series, the switching speed tends to become slow when connecting a resistance load.

Here you will find the switching function comparison of two models and learn how PLZ5W Series has improved this function.

1. Switching Test: PLZ5W Series vs. PLZ4W Series

Compare the current rise time in two conditions: with/without resistance load connected. Ideally the both current can rise at the same speed; however it may not be so.

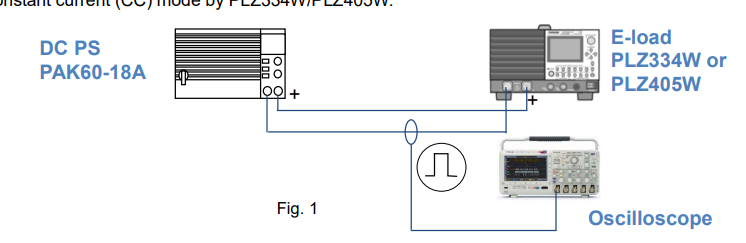

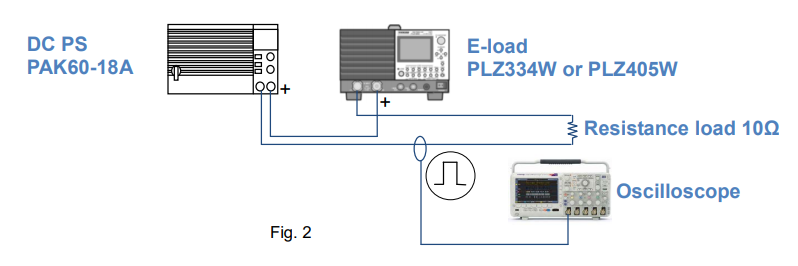

Test Device: PLZ334W and PLZ405W – relatively similar power capacity

Test Condition: Set the power supply voltage to 50 VDC and electronic load current to 4 A.1) Test Circuit without Resistance Load Connected

Connect PLZ334W/PLZ405W in parallel to PAK60-18A. Perform the switching function in constant current (CC) mode by PLZ334W/PLZ405W.

2) Test Circuit with Resistance Load Connected

Connect PLZ334W/PLZ405W and a resistance load in series to PAK60-18A. Perform the switching function in CC mode by PLZ334W/PLZ405W.

2. Test Results

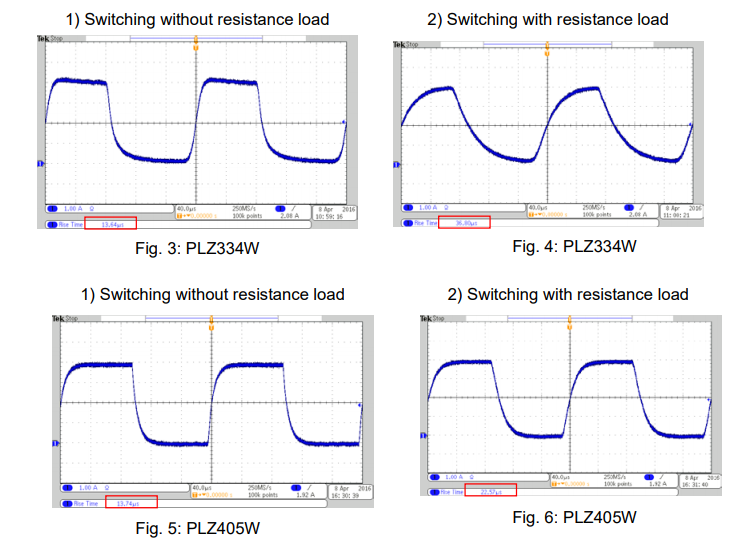

2-1 Switching Rise Time ComparisonPLZ334W (See Figure 3 and 4):

1) Without resistance load: approx. 14 μs → 2) With resistance load: approx. 37 μs PLZ405W (See Figure 5 and 6):

1) Without resistance load: approx. 14 μs → 2) With resistance load: approx. 22 μs Obviously, PLZ405W can achieve the faster switching speed with a resistance load.

2-2 Switching Rise Time Comparison – Faster Speed

PLZ405W (See Figure 7 and 8):

1) Without resistance load: approx. 5 μs → 2) With resistance load: approx. 17 μs

PLZ334W cannot reach this speed; the rise time will be approx. 37 μs as showing Figure 4.

2-3 PLZ405W: Rise Time Relations with/without Resistance Load Connected

3. Conclusion

While the switching is performed with a resistance load, the voltage fluctuates at the electronic load input terminal as below:

In conclusion, the test results prove that PLZ5W Sires can offer the higher switching speed than PLZ4W Series in both conditions of with/without resistance load connection (which means regardless of the voltage fluctuation at the electronic load input terminal). This is because the capacitor capacitance of PLZ5W Series has been reduced compared to the previous PLZ4W Series.

Table 1 shows the value of capacitor and resistor in PLZ5W and PLZ4W Series and Figure 11 shows the equivalent circuit.

The C1 capacitance increases according to increasing power capacity of PLZ5W and PLZ4W (See Table 1).

*As the reference; the rise time of PLZ405W without a resistance load is approx. 13.7 μs (See Figure 5). When the C1 and R1 value of PLZ405W are changed to those of PLZ1205W as above, the switching rise time with a resistance load is clearly slowing down to approx. 61.5 μs (See Figure 12).

When performing the switching operation with a resistance load, we encourage you to use a smaller capacity electronic load as possible.

Products Mentioned In This Article:

PLZ-5W Series please see HERE

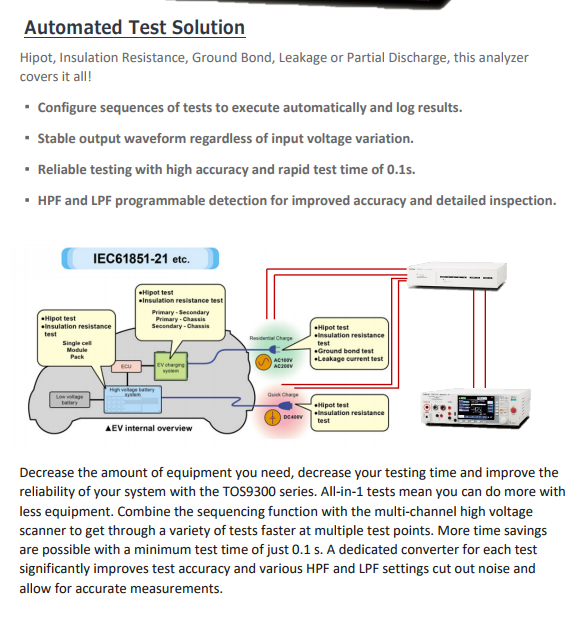

When to use the LPF Setting TOS9300 Series

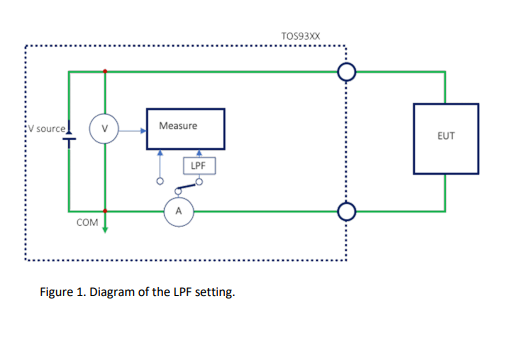

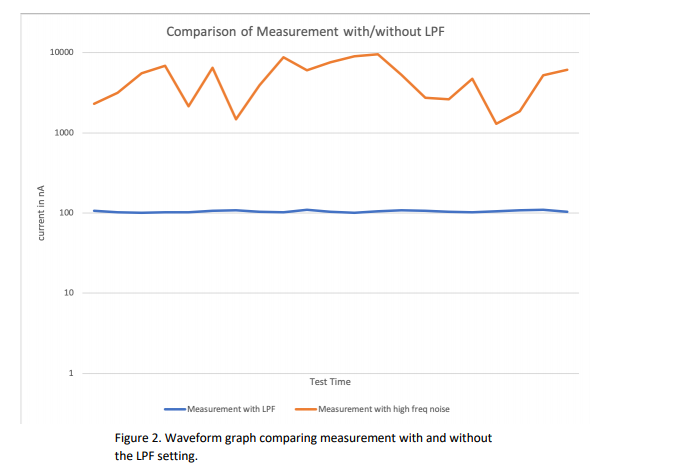

The TOS9300 series of electrical safety testers is a robust all-in-one solution. When performing AC Hipot, DC Hipot and Insulation Resistance tests there are setting options which allow the user to optimise testing as necessary for all applications. In certain situations where EUT’s are being tested for very high insulation resistances the LPF can be used to significantly improve the accuracy of the tester.

WHEN TO USE THE LPF SETTING

The LPF of the TOS9300 series is a second order Bessel filter with a 3dB cutoff at 1 kHz. This filter was designed to remove the transmission line noise that causes stray capacitance to affect the measurement. Any application that expects an insulation resistance measurement higher than 50 M ohm should consider using the LPF.

When measuring high insulation resistances at high voltages we expect to see very low currents measured at the ammeter because of Ohm’s Law. Readings where the expected current is only nA are greatly affected by high frequency noise. This type of noise is hard to avoid so it is useful to have a LPF which removes the high frequency current components just before measurement. It should be noted that a longer test time should be used to compensate for the lower frequency signal being measured in the test. See the operation manual for more information.

Products Mentioned In This Article:

- TOS9300 Series please see HERE

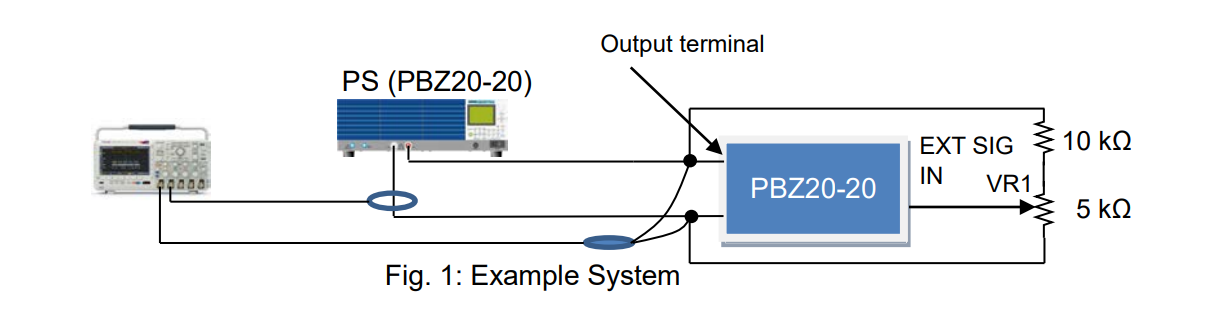

Using Bipolar Power Supply PBZ Series as AC Electronic Load

In this white paper, we are going to share the techniques to make the system that our bipolar power supply PBZ Series acts as a constant resistance load.

1. System Details

First, we are describing the system. See Figure 1 below; two units of PBZ20-20 are required for the system to operate as an AC electronic load ‘PBZ20-20’ and an AC power supply ‘PS (PBZ20-20)’:

1. CC mode is set on PBZ20-20.

2. The resistances are placed at the output terminal of PBZ20-20 to divide the voltage.

3. The divided voltage is applied via EXT SIG IN (BNC) to control the output current from PBZ20-20.

4. When the AC voltage is applied from PS, PBZ20-20 operates as a constant resistance load.

5. To adjust the current, connect a variable resistance (VR1) to EXT SIG IN.

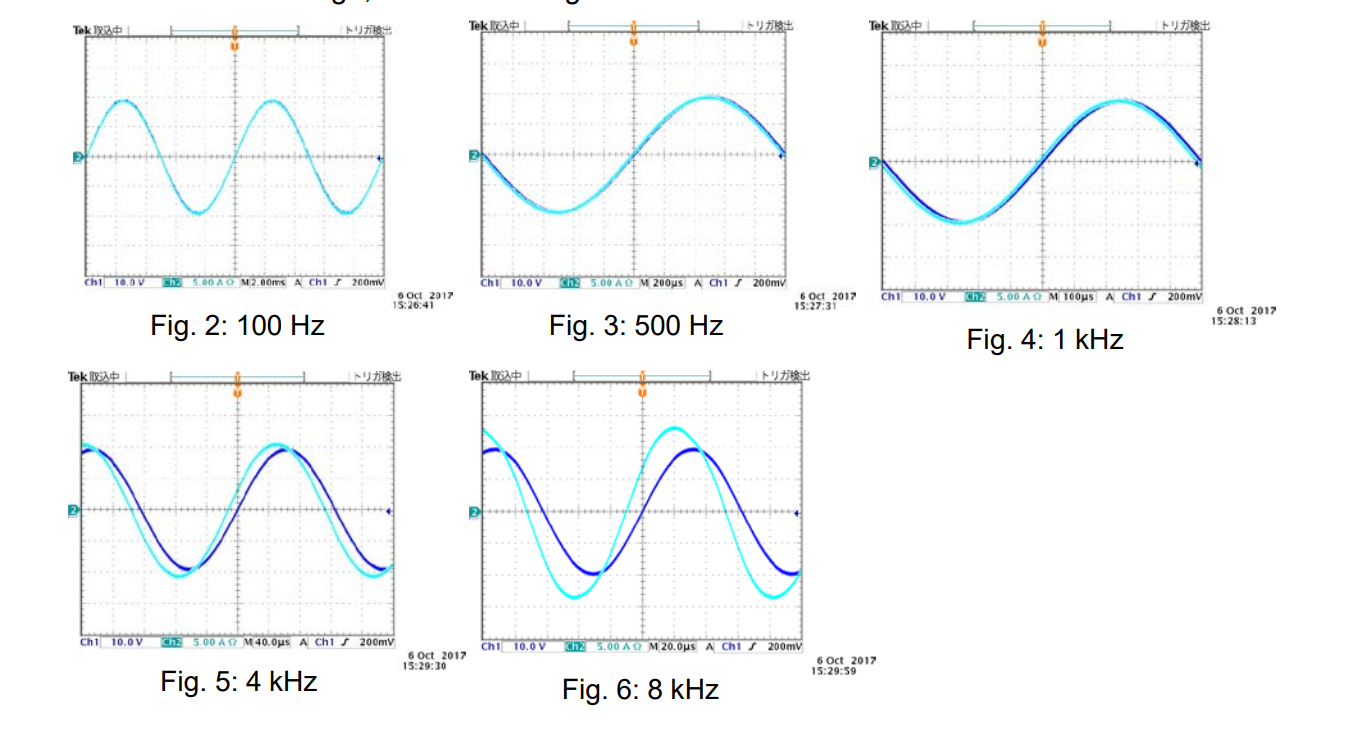

2. Test Results

Next, let’s look at the test results on this system.

Given below are the phase relationships between the voltage and current under this system. Figure 2 – 6 show the input AC voltage waveforms and current waveforms:

Test Conditions: PS PBZ20-20: 40 VP-P, PBZ20-20: 40 AP-P specified by VR1 Waveform in blue: Voltage, Waveform in light blue: Current

3. Conclusion

As the frequency is getting higher, the current leads the voltage. This implies that PBZ20-20 operates like a capacitive load at the higher frequency in this system. When the sinewave frequency is 8 kHz (Fig. 6), the phase difference between the voltage and the current is approx. 28°. From this phase difference, the power factor will be 0.88.Products Mentioned In This Article:

- PBZ Series please see HERE

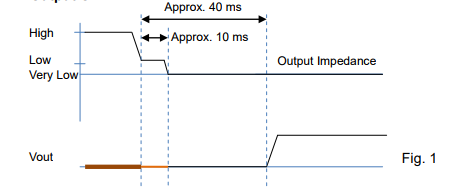

Output On/Off Behaviour of PBZ Series

For PBZ Series, a magnetic relay is used to turn the output on/off. The relay is off to turn the output off; when the output is off, the output is in the high impedance state.

In addition, if the output-on/off is controlled by an external signal input, the embedded firmware in PBZ may cause a jitter on the output voltage.

Now we are going to focus on the following two topics of the output on/off behaviour of PBZ and explain how:

1. the output voltage and output impedance change during the output on/off operation

2. PBZ responses to the output-on/off external signal input.1. Change in Output Voltage and Output Impedance during Output-On/Off Operation

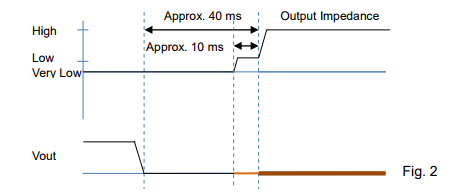

Figure 1 shows: change in the output voltage (Vout) and output impedance when the output is turned on. Figure 2 shows: change in Vout and output impedance when the output is turned off.

* The rise and fall time of Vout is dependent on the response setting by PBZ.1-1. Output On

1-2. Output Off

Output Impedance:

High:

・ PBZ20-20: 120 kΩ ・ PBZ40-10: 220 kΩ ・ PBZ60-6.7: 320 kΩ ・ PBZ80-5: 420 kΩ Low:

・ a few hundred Ω Very Low:

・ Output is turned on.1-3. Recommended Method to Frequently Turn Output On/Off

If you want to repeatedly switch the output on/off over a long period of time, we recommend the following procedures to prolong the lifetime of the relay:

1. Keep the output on.

2. To turn the output off, set the output voltage (Vset) to 0 V.

For DC output only: If you want to set the high impedance when the output is off, place a diode in series with the output terminal of PBZ and set Vset to 0 V.

* For the battery charging application, also place a diode in series with the output terminal of PBZ.

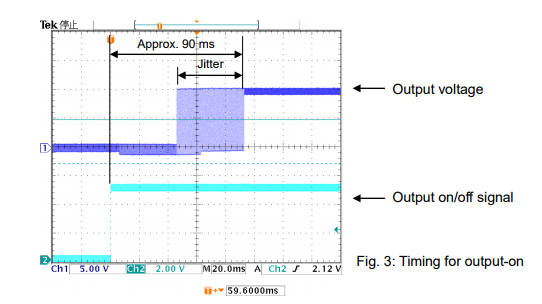

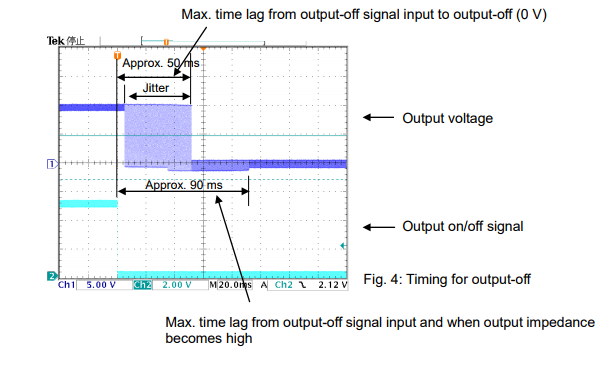

2. Output-On/Off Response to External Signal

In Figure 3 and 4, you can find the jitters when the output is turned on/off via the external signal input: ● Signal lag for output-on: approx. 90 ms max.

● Signal lag for output-off: approx. 50 ms max. ● Jitter during output-on/off: approx. 45 ms

In Figure 4, the lag between the output-off signal input and when the output impedance becomes high is approx. 90 ms max. and the jitter is approx. 45 ms; this lag is 50 ms min. and 90 ms max.

2-1. Output On

2-2. Output Off

Products Mentioned In This Article:

PBZ Series please see HERE

Precautions When Operating AC Power Supply ‘PCR-LE Series’ in DC Mode

PCR-LE/LE2 Series can produce a DC output that enables you to test DC-powered devices such as DC-input converters. This article introduces the important precautions and useful functions to effectively operate PCR-LE/LE2 Series in DC mode.

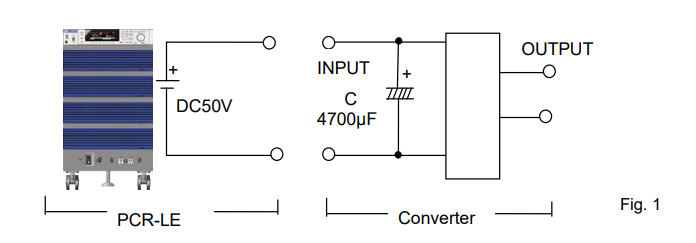

1. Circuit Model

See Figure 1 for the test circuit model with PCR-LE. It illustrates the DC-input converter/inverter that has a capacitor-input circuit but without an inrush current prevention circuit.

2. Rated DC Current and Maximum Instantaneous Current

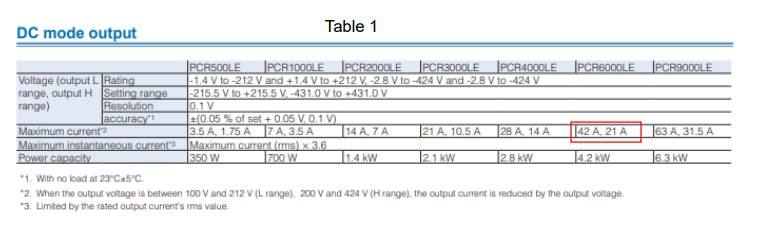

2-1 Rated DC Current for PCR6000LE

From Table 1;

DC input 200V: The rated DC current (maximum current) is 21A. The maximum instantaneous current, 3.6 times the rated DC current, is 75.6A.

DC input 100V: the rated DC current is 42A. The maximum instantaneous current is 151.2A. The rated DC current is 70% of the rated AC current.

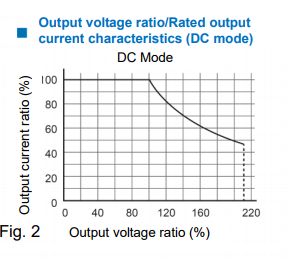

From Figure 2;

Example 1) If DC input is 100V and the output voltage is DC50V; the output voltage ratio is 50% → The output current ratio is 100% → The output current equals the rated DC current.

Example 2) If DC input is 200V and the output voltage is DC400V; the output voltage ratio is 200% → The output current is limited by 50% → The rated DC current is 10.5A and the maximum instantaneous current is 37.8A.

2-2 Maximum Instantaneous DC Current

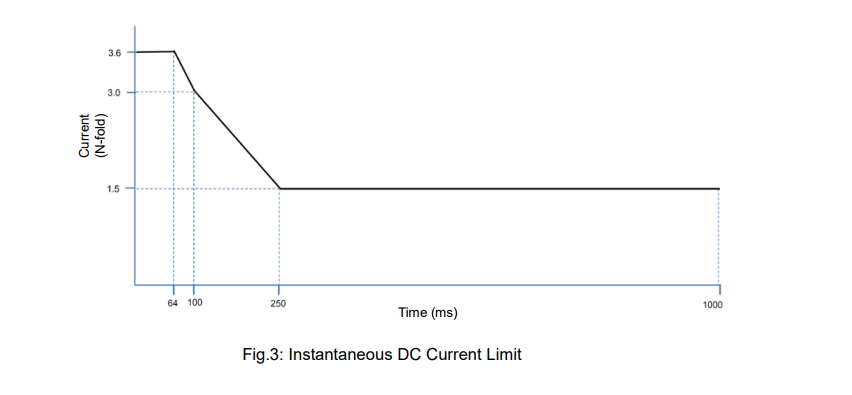

As stated above, the maximum instantaneous current is 3.6 times the rated DC current. The overcurrent protection (OCP) in PCR-LE activates when the output DC current exceeds the maximum instantaneous current. See Figure 3 for the DC current limit characteristics. DC current can remain within this limit. If the RMS DC current exceeds the limit for 1 second or more, the overload alarm is triggered to shut off the current.

3. Inrush Current

The rise time of PCR-LE is less than approx. 80μs in any response setting. While large inrush current would flow to the model circuit shown in Figure 1, PCR-LE equipped the current limit circuit can hold the DC current level to the maximum instantaneous current. If the RMS DC current exceeds the limit for 1 second or more, the overload alarm is triggered to shut off the current. The alarm can be cancelled by pressing the ALARM CLR key.

To prevent such inrush current, the power supply capacity should be increased. In PCR-LE, you just turn Soft Start on to raise the output voltage gradually and limit the current through the capacitor. To set Soft Start, press OTHERS (SHIFT + MEMORY) > RISETIME (F1).4. Impedance when output is off

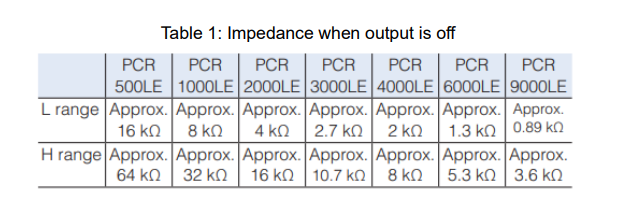

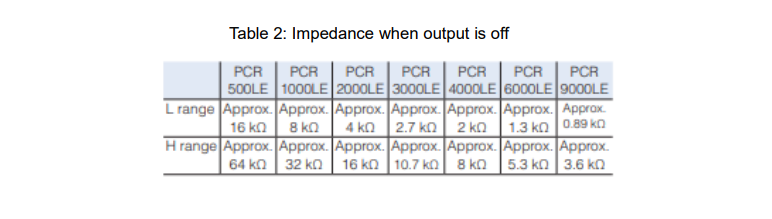

When an output is turned off, PCR-LE has a high impedance as shown in Table 2 (approx. several kΩ to several tens kΩ). As shown in Figure 4, the voltage reaches 0V for approx. 200μs when the output is turned off, and then PCR-LE is in a high impedance state. During this 200μs, the capacitor in Figure 1 discharges its electric charge and the OCP activates to shut off the current.

Table 2: Impedance when output is off

If you have any trouble during this 200μs, it is recommended that you insert a diode in series for the PCR-LE output or set COFIG > Surge Suppression > OFF to leave the high impedance (Voltage does not reach 0V). To set surge suppression, press CONFIG (SHIFT + OPR MODE) > 1/2 (F6) > SURGE S (F2) > OFF (F/W Ver.4.50 or later).

5. Others

PCR-LE uses a high-speed amplifier. The output may become unstable due to capacitive loads or wiring conditions. With such loads, we recommend that you change the response setting to SLOW to keep stable operations.

To set the response, press OTHERS (SHIFT + MEMORY) > 1/3 > RESP.Products Mentioned In This Article:

PCR-LE Series please see HERE

Output Connection Methods with Parallel Control

Parallel operation is very useful to expand an output capacity; especially master-slave parallel operation allows you to control an entire system by one master unit.

When making the master-slave connection such as signal wiring and load connection, you may find some issues with load connection. Improper connection may cause oscillation so that our user’s manual describes how to connect the load.

In this article, you will learn not only the basic connection methods also the advanced techniques to stabilize an unstable output, which can apply to almost all our DC power supplies (except for high-speed power supply PBZ Series).

1. Basic Connection Methods

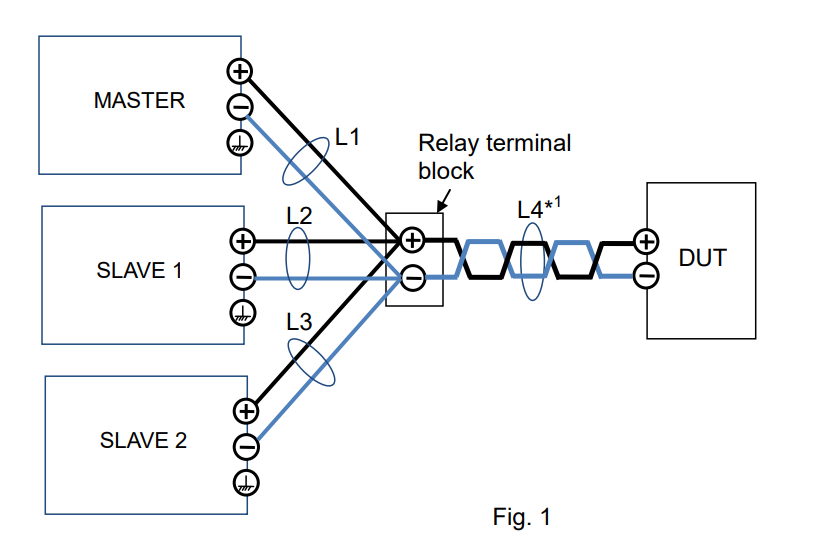

1) Make the cable connection between the master/slave units and DUT as short as possible and each connection should be the same length; In Figure 1, the cable connection L1, L2 and L3 should be the same length and then connect them to the DUT as short as possible.

2) If the above cable length is too long, connect the master/slave units to a relay terminal block as short as possible. Then, tightly twist the relay terminal block cables and connect them to the DUT at an appropriate length (See L4 in Figure 1).

See Figure 1 for the example:

*1: The L4 cables should withstand the total current from the master and slave 1 & 2.

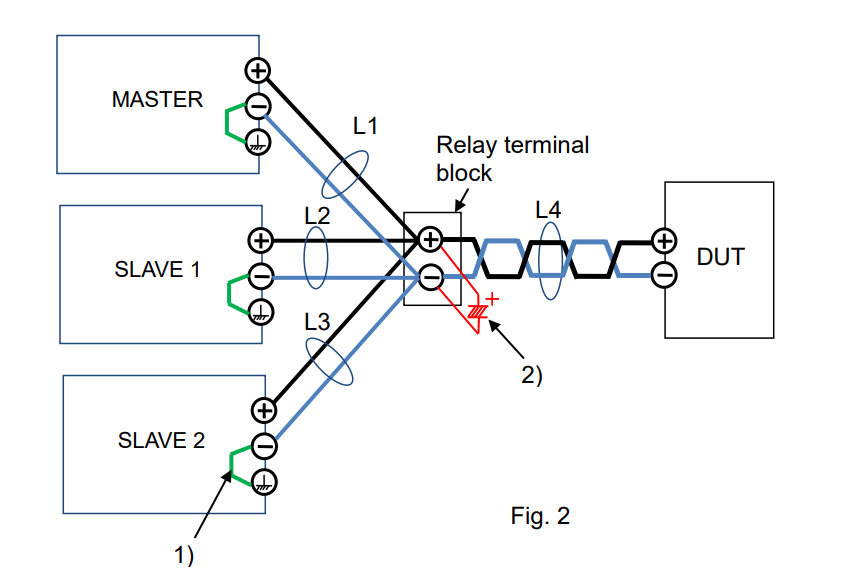

2. Advanced Connection Methods

If the output becomes unstable under the basic connection, the following methods are available. Use all or any of three methods as required.

1) Ground either the positive or negative terminal of output (See the green lines in Figure 2). If either of the DUT input is grounded, check if short circuit may occur due to the output grounding.

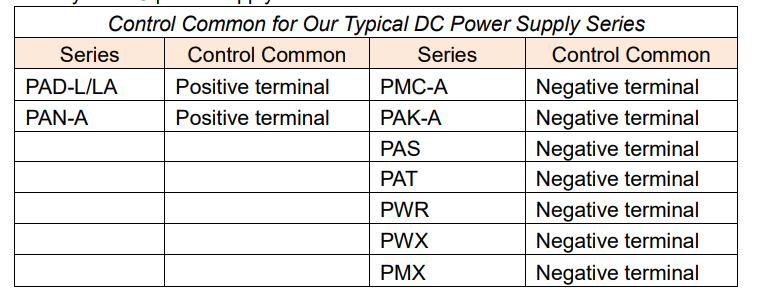

For the parallel operation, you also need to check that all paralleled DC power supplies have the same control common terminal. Keep in mind that the control common terminal differs by our DC power supply series as follows:

2) Add a large capacitor to the relay terminal block (See the red lines in Figure 2). If high speed power supply such as PBZ Series has been used, avoid this method.

Products Mentioned In This Article:

To view Kikusui’s DC Power Supply range please see HERE